Title: Ultimate Packaging Solution: Automatic 10-Piece Mask Bag Packaging Machine

Description:

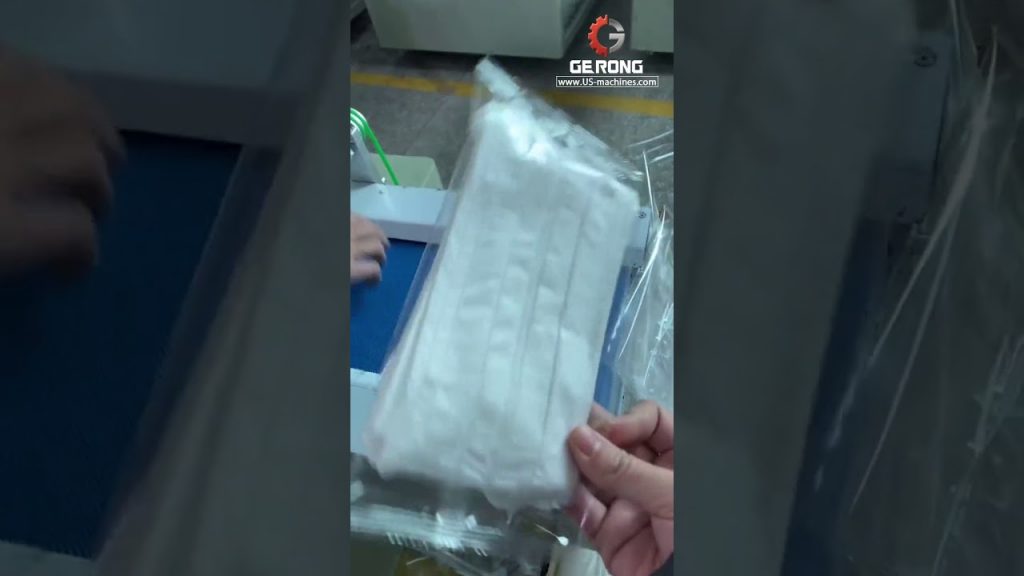

Welcome to the world of cutting-edge packaging technology with the Automatic Packaging Line and its star performer, the Automatic 10-Piece Mask Bag Packaging Machine. This innovative machine, designed to meet both Chinese and U.S. standards, revolutionizes the packaging process for mask bags, ensuring efficiency and precision.

🔹 Introduction:

In this video, we delve into the advanced features and benefits of the Automatic 10-Piece Mask Bag Packaging Machine. Whether you're a manufacturer or a business owner, this video will provide you with valuable insights into optimizing your packaging operations.

🔹 Video Content:

Discover the remarkable capabilities of the Automatic 10-Piece Mask Bag Packaging Machine as we explore its key features and functionalities. From its state-of-the-art technology to its seamless operation, this machine guarantees increased productivity and cost-effectiveness.

🔸 Key Highlights:

✅ Unparalleled Efficiency: With its automatic packaging line, this machine can swiftly handle the packaging of 10 mask bags simultaneously, significantly reducing manual labor and production time.

✅ Precision Packaging: The machine ensures precise sealing, preventing any leakage or damage to the masks. This guarantees the highest quality packaging, maintaining the integrity of the products.

✅ Versatility: The Automatic 10-Piece Mask Bag Packaging Machine adapts to various mask bag sizes, allowing for flexibility in your packaging requirements.

✅ User-Friendly Interface: Experience hassle-free operation with its intuitive control panel, enabling easy customization and adjustment of packaging settings.

✅ Robust Construction: Built with durable materials and adhering to stringent quality standards, this machine offers long-lasting performance and reliability.

🔹 Operation Steps:

Step 1: Load the mask bags onto the feeding conveyor.

Step 2: Adjust the machine settings according to the desired packaging specifications.

Step 3: Activate the machine, and witness the automatic packaging process in action.

Step 4: The machine completes the packaging, ensuring each mask bag is perfectly sealed and ready for distribution.

🔹 Call to Action:

If you found this video insightful, don't forget to like, subscribe, and share it with others who might benefit from this technology. Stay updated with the latest advancements in packaging solutions by joining our community.

🔹 Additional Tags and Keywords:

Automatic Packaging Line, Mask Bag Packaging Machine, Packaging Automation, Advanced Packaging Solutions, Packaging Technology, Manufacturing Efficiency, Precise Packaging, Packaging Equipment, Packaging Innovation

🔹 Hashtags:

#AutomaticPackaging #MaskBagPackaging #PackagingAutomation #AdvancedPackaging #PackagingTechnology #ManufacturingEfficiency

Here's a potential tilter for an automatic 10-piece mask bag packaging machine:

Title: Automatic 10-Piece Mask Bag Packaging Machine Tilter

Introduction:

The Automatic 10-Piece Mask Bag Packaging Machine Tilter is a crucial component of the mask bag packing line, designed to efficiently and accurately tilt mask bags for optimal packaging. This tilter ensures seamless integration with the packaging machine, enhancing productivity and reducing manual effort. With its advanced features, it guarantees precise positioning and consistent performance, making it an indispensable tool for the mask bag packing line.

Features:

1. Robust Construction:

The tilter is built with high-quality materials, ensuring durability and long-lasting performance. Its sturdy frame provides stability during operation, minimizing vibrations and maintaining precision.

2. Motorized Tilt Mechanism:

Equipped with a powerful motor, the tilter offers automated tilting of the mask bags. This eliminates the need for manual intervention, saving time and reducing labor costs. The motorized tilt mechanism ensures smooth and controlled movements, preventing any damage to the mask bags.

3. Adjustable Tilt Angle:

The tilter allows for adjustable tilt angles, catering to various packaging requirements. This flexibility enables the machine to handle different sizes and shapes of mask bags, accommodating the production needs effectively.

4. Sensor-Based Positioning:

Incorporating advanced sensors, the tilter precisely detects the position of the mask bags. This accurate positioning ensures consistent alignment with the packaging machine, minimizing errors and optimizing the packaging process.

5. User-Friendly Interface:

The tilter features a user-friendly interface, allowing operators to easily control and monitor the tilting operations. The intuitive controls enable swift adjustments of tilt angles, ensuring seamless integration with the rest of the packaging line.

6. Safety Measures:

Safety is a top priority, and the tilter is equipped with safety features to protect both the machine and operators. Emergency stop buttons, safety guards, and automatic shutdown in case of malfunctions or abnormalities ensure a secure working environment.

7. Easy Maintenance:

The tilter is designed for easy maintenance, with accessible components and clear instructions for routine upkeep. This minimizes downtime and maximizes productivity, keeping the packaging line running smoothly.

Conclusion:

The Automatic 10-Piece Mask Bag Packaging Machine Tilter is an essential component of the mask bag packing line, offering automated and precise tilting of mask bags for optimal packaging. With its robust construction, adjustable tilt angles, sensor-based positioning, user-friendly interface, and safety measures, this tilter enhances productivity, reduces manual effort, and ensures consistent performance. Embrace this tilter to streamline your mask bag packaging process and elevate your production efficiency. Automatic Packing Line

#Automatic #pieces #mask #bag #packaging #machine #mask #bag #packing #line