Title: Efficient Pallet Handling Machine: Revolutionizing Logistics Operations | IDEALMACHINERY

Description:

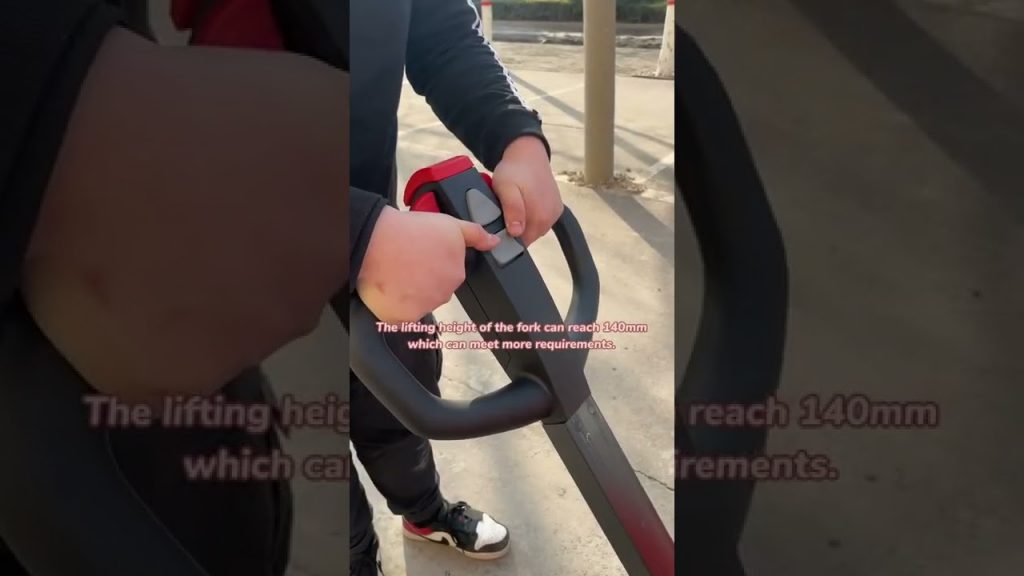

Are you tired of manual labor and looking for an innovative solution to optimize your pallet handling process? Look no further! IDEALMACHINERY presents an exceptional Pallet Handling Machine that will revolutionize your logistics operations. With its advanced technology and exceptional capabilities, this machine ensures efficient and seamless movement of pallets, providing significant time and cost savings.

Video Content:

In this informative video, we delve into the remarkable features and benefits of our Pallet Handling Machine. Discover how this state-of-the-art equipment streamlines pallet transportation, improving productivity and reducing manual effort. We present a step-by-step overview of its operation, highlighting its efficiency, reliability, and ease of use. Witness the machine's ability to handle pallets of varying sizes and weights effortlessly, eliminating the risk of injuries and enhancing workplace safety.

Key Highlights and Interesting Facts:

1. Cutting-Edge Technology: Our Pallet Handling Machine incorporates cutting-edge automation and robotics, ensuring precise and accurate pallet movement, stacking, and retrieval.

2. Customizability: Tailored to meet your specific requirements, this machine can be adjusted for various pallet sizes, weights, and load capacities, offering versatility in your operations.

3. Time and Cost Savings: By automating the pallet handling process, this machine significantly reduces labor costs, minimizes operational downtime, and optimizes overall efficiency.

4. Enhanced Safety: With built-in safety features, such as collision detection and emergency stop functionality, the machine ensures the well-being of your workforce and prevents accidents.

5. Seamless Integration: Our Pallet Handling Machine seamlessly integrates with existing warehouse management systems, allowing for smooth coordination and enhanced workflow.

Call to Action:

If you're ready to revolutionize your pallet handling operations and boost efficiency, don't miss out on this game-changing solution! Like, subscribe, and share this video to stay updated with the latest innovations in the industry. For more information and to explore how our Pallet Handling Machine can transform your logistics operations, contact our team at [insert contact details].

Additional Tags and Keywords: pallet handling machine, pallet truck, pallet machinery, automated pallet handling, logistics automation, warehouse efficiency, robotics in logistics, IDEALMACHINERY.

Hashtags: #pallet #handling #machine #truck #IDEALMACHINERY #automation #logistics

Here is a sample code for a tilt control system for a pallet truck using Arduino:

```C++

#include

Servo tiltServo; // Create servo object to control the tilt angle

int tiltPin = A0; // Analog pin to read the tilt sensor value

int tiltThreshold = 500; // Threshold value for tilt detection

void setup() {

tiltServo.attach(9); // Attach the servo to pin 9

Serial.begin(9600); // Initialize serial communication

}

void loop() {

int tiltValue = analogRead(tiltPin); // Read the tilt sensor value

if (tiltValue > tiltThreshold) {

// Tilt detected, tilt the pallet truck

tiltServo.write(90); // Set the servo angle to tilt at 90 degrees

delay(500); // Delay to allow the pallet truck to tilt

tiltServo.write(0); // Reset the servo angle to 0 degrees

delay(500); // Delay to allow the pallet truck to stabilize

}

Serial.println(tiltValue); // Print the tilt sensor value for debugging

delay(100); // Delay between readings

}

```

In this code, we first include the Servo library to control the servo motor. We then create a `Servo` object named `tiltServo` to control the tilt angle of the pallet truck.

The `tiltPin` variable is set to the analog pin (`A0`) connected to the tilt sensor. The `tiltThreshold` is a value that determines when a tilt is detected.

In the `setup()` function, we attach the servo to pin 9 and initialize the serial communication at a baud rate of 9600.

The main logic is implemented in the `loop()` function. We read the tilt sensor value using `analogRead(tiltPin)` and store it in the `tiltValue` variable. If the `tiltValue` exceeds the `tiltThreshold`, we tilt the pallet truck by setting the servo angle to 90 degrees using `tiltServo.write(90)`. We then introduce a delay to allow the truck to tilt using `delay(500)`. After that, we reset the servo angle to 0 degrees using `tiltServo.write(0)` and introduce another delay to allow the truck to stabilize.

Finally, we print the `tiltValue` to the serial monitor for debugging purposes and introduce a delay between readings using `delay(100)`.Handling Machine

#Pallet #truck