Are you interested in learning more about the processes involved in making a wide range of plastic products? Look no further than this educational tool from Conair. In this YouTube video, we will explain the injection, extrusion, and blow molding processes used in plastic manufacturing. Whether you are a student, engineer, or simply curious about how everyday items are made, this video is perfect for you.

Plastic injection molding is a widely used process in the manufacturing industry. It involves injecting molten plastic into a mold cavity, allowing it to cool and solidify, and then ejecting the finished product. This process is suitable for producing a variety of complex shapes and sizes, making it a popular choice for mass production.

Extrusion is another important process in plastic manufacturing. It involves forcing molten plastic through a die, which shapes the plastic into a continuous profile. This process is commonly used for creating products such as pipes, tubes, and sheets. By understanding the extrusion process, you can gain a deeper appreciation for the products you use on a daily basis.

Blow molding is yet another fascinating process in plastic manufacturing. It involves inflating a heated plastic tube, known as a parison, inside a mold cavity to create hollow objects. This process is commonly used for producing bottles, containers, and other similar products. By learning about blow molding, you will gain insights into the techniques used to create these everyday items.

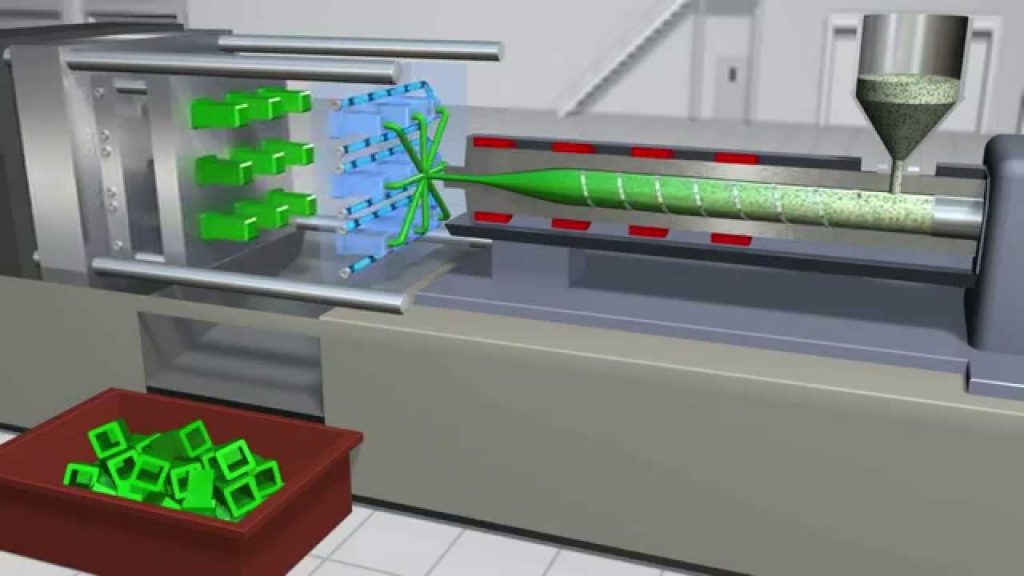

Now that you have a basic understanding of the injection, extrusion, and blow molding processes, let's delve into the world of plastic injection machines. A plastic injection machine, also known as an injection molding machine, is a crucial piece of equipment used in the plastic manufacturing industry. It is responsible for injecting molten plastic into molds and ensuring the precise formation of the desired product.

Plastic injection machines come in various sizes and configurations, depending on the specific manufacturing requirements. They consist of several components, including a hopper, heater bands, a reciprocating screw, and a mold clamping unit. These machines offer a high degree of control and precision, making them ideal for creating intricate and detailed plastic products.

In conclusion, this educational tool from Conair provides a comprehensive overview of the injection, extrusion, and blow molding processes used in plastic manufacturing. By understanding these processes and the role of plastic injection machines, you will gain a deeper appreciation for the wide range of plastic products that surround us in our daily lives.

Check out the video to learn more about plastic injection machines and how they contribute to the production of everyday items. Enhance your knowledge and discover the fascinating world of plastic manufacturing!

Check the coil packing solution with a leading manufacturer for the professional solution just here. Plastic Injection Machine

"Understanding Plastic Processing: A Comprehensive Overview of Plastic Injection Machines"