Plastic Injection Machine: A Revolution in Manufacturing

Introduction:

In the world of manufacturing, plastic injection machines have emerged as a game-changer. These machines have revolutionized the production process by enabling efficient and cost-effective manufacturing of plastic products. This article will delve into the details of plastic injection machines, their working mechanism, and their significance in the manufacturing industry.

What is a Plastic Injection Machine?

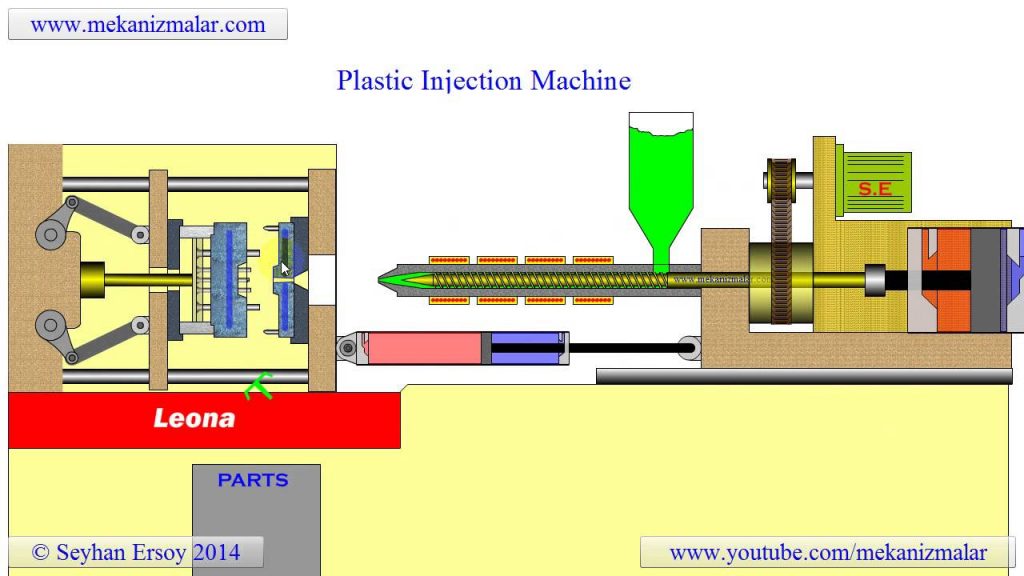

A plastic injection machine, also known as an injection molding machine, is a device used to create plastic products through the injection molding process. It consists of several essential components, including an injection unit, a clamping unit, and a mold. The machine melts plastic pellets and injects the molten material into a mold cavity, where it solidifies and takes the desired shape.

Working Mechanism of a Plastic Injection Machine:

The working mechanism of a plastic injection machine involves several steps. Let's take a closer look at each of these steps:

1. Clamping:

The first step of the injection molding process is clamping. The mold halves are securely closed and clamped together, creating a cavity for the plastic material.

2. Injection:

Next, plastic pellets or granules are fed into the injection unit. The pellets are heated and melted, forming a molten plastic material. This molten material is then injected into the mold cavity under high pressure.

3. Cooling and Solidification:

Once the molten plastic is injected into the mold cavity, it begins to cool and solidify. This cooling process is crucial for ensuring the final product's quality and dimensional accuracy.

4. Ejection:

After the plastic has solidified, the mold opens, and the newly formed plastic product is ejected from the machine. The cycle then repeats for the production of additional parts.

Significance of Plastic Injection Machines:

Plastic injection machines have gained immense significance in the manufacturing industry due to the following reasons:

1. Cost-effective Production:

Injection molding allows for high-volume production at a lower cost per unit. The automation and efficiency of plastic injection machines contribute to reducing production costs, making them a preferred choice for manufacturers.

2. Versatility:

Plastic injection machines offer great versatility in terms of the types of products that can be manufactured. From intricate and complex components to simple everyday items, these machines can produce a wide range of products with ease.

3. Enhanced Efficiency:

The automation and precision of plastic injection machines result in improved efficiency. With faster cycle times and minimal wastage of material, manufacturers can achieve higher productivity levels.

4. Quality and Consistency:

Injection molding ensures consistent and high-quality production. The controlled environment of a plastic injection machine ensures that each product is manufactured with precision, meeting the required specifications.

Conclusion:

Plastic injection machines have revolutionized the manufacturing industry by enabling efficient and cost-effective production of plastic products. From reducing production costs to ensuring high-quality output, these machines have become an integral part of the manufacturing process. As the demand for plastic products continues to grow, the importance of plastic injection machines will only increase.

Check the coil packing solution with a leading manufacturer for a professional solution. Contact us today! Plastic Injection Machine

"Efficient Plastic Injection Machine: Boost Your Production with Advanced Technology"