If you're in the industrial sector, you understand the importance of efficient packing systems. The right packing system can save time, money, and resources, while ensuring that your products are securely packaged for transport or storage. In this YouTube video, we will explore the benefits of industrial packing systems and showcase the FANUC M-420iA Cookie Picking & Packing Robot, a leading solution in industrial automation.

Industrial packing systems play a crucial role in various industries such as food and beverage, pharmaceuticals, electronics, and automotive. These systems are designed to streamline the packing process, minimize human error, and optimize productivity. With advancements in technology, packing systems have evolved to incorporate robotics and automation, offering even greater efficiency and precision.

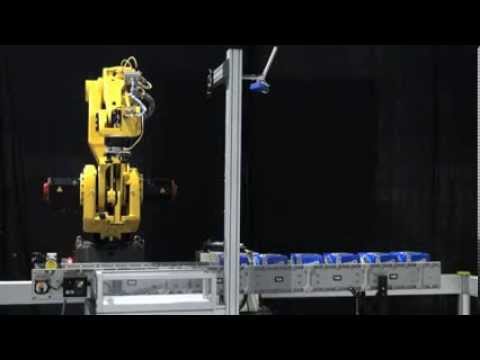

The FANUC M-420iA Cookie Picking & Packing Robot is a perfect example of how automation can revolutionize industrial packing. This robot is specifically designed for picking and packing applications, making it ideal for industries that require high-speed and accurate packaging. Equipped with intelligent vision systems, the M-420iA robot can identify and handle products of various shapes, sizes, and materials, ensuring consistent and reliable packing results.

One of the key advantages of the FANUC M-420iA robot is its ability to increase productivity. With its high-speed operation and precise movements, this robot can significantly reduce packing time compared to manual labor. By automating the packing process, companies can achieve higher output rates, meet tight production deadlines, and ultimately enhance their overall operational efficiency.

Furthermore, the M-420iA robot offers improved product quality and consistency. Human error is inevitable, and it can lead to packaging defects or inconsistencies. However, with the robot's advanced vision system and programming capabilities, it can consistently apply the correct packing methods, ensuring that each product is packaged accurately and securely.

In addition to its productivity and quality benefits, the M-420iA robot also enhances workplace safety. Industrial packing often involves handling heavy or bulky items, which can pose risks to workers. By automating these tasks, companies can minimize the risk of injuries and create a safer work environment for their employees.

As technology continues to advance, industrial packing systems are becoming more intelligent and adaptable. The integration of artificial intelligence and machine learning enables packing systems to learn and improve over time. This means that the packing process can be continuously optimized, leading to even greater efficiency and cost savings.

In conclusion, industrial packing systems are essential for businesses in various industries. They offer numerous benefits, including increased productivity, improved product quality, and enhanced workplace safety. The FANUC M-420iA Cookie Picking & Packing Robot exemplifies the power of automation in industrial packing, providing companies with a reliable and efficient solution.

Check the coil packing solution with the leading manufacturer for the professional solution just here. Packing System

"Efficient and Automated Cookie Picking & Packing with the FANUC M-420iA Robot - Industrial Packing System"