Title: Fully Automated Packaging Line for Samosas | Animation at Aliya's Foods

Description:

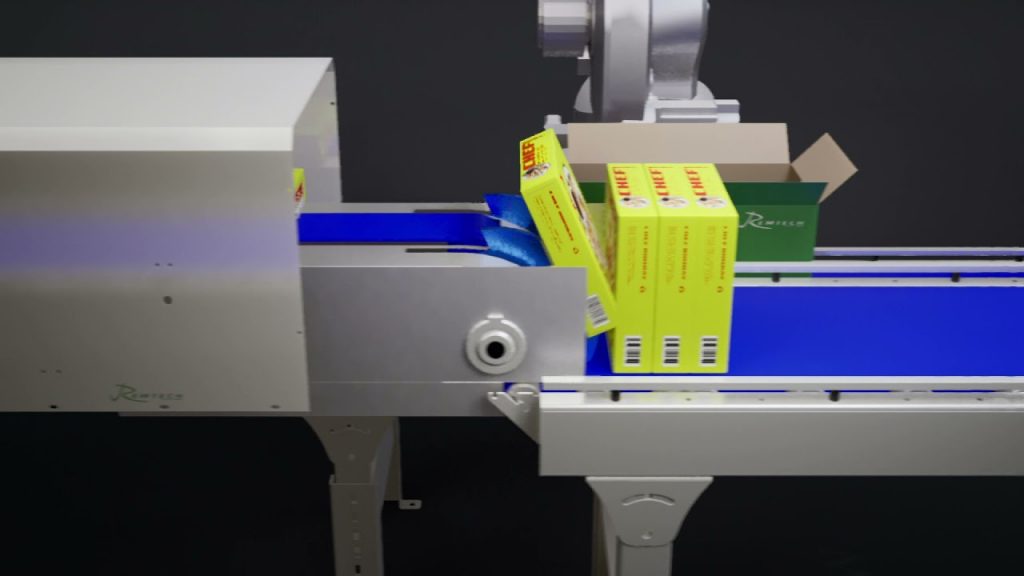

Welcome to Aliya's Foods, where innovation meets efficiency in our fully automated packaging line for samosas. In this captivating animation, witness the seamless process of packaging samosas with utmost precision and speed. Our state-of-the-art technology ensures that each samosa is carefully handled, packed, and ready for distribution.

Introduction:

Experience the future of packaging with Aliya's Foods! This mesmerizing animation showcases our advanced automatic packaging line for samosas. Get ready to be amazed by the seamless operation and unparalleled efficiency of our cutting-edge machinery.

Video Content:

Discover how our automated packaging line revolutionizes the way samosas are packaged. From the moment the samosas enter the line, our technology takes over, ensuring each step is flawlessly executed. Here are the key points covered in the video:

1. Precise Sorting: Our packaging line starts with the meticulous sorting of samosas, ensuring uniformity in shape and size.

2. Hygienic Handling: Witness the hygienic handling of samosas throughout the packaging process, eliminating any risk of contamination.

3. Accurate Weighing: Our advanced weighing system guarantees that each samosa meets the desired weight requirements.

4. Seamless Packaging: Experience the seamless packaging process as the samosas are individually wrapped in high-quality materials.

5. Efficient Sealing: Our automated sealing machines ensure airtight packaging, preserving the freshness and flavors of the samosas.

6. Quality Control: Explore how our packaging line incorporates rigorous quality control measures to maintain the highest standards.

Call to Action:

If you enjoyed this mesmerizing animation of our automated packaging line for samosas, don't forget to like, subscribe, and share the video. Stay updated with our latest innovations in the food industry. Subscribe now to Aliya's Foods for more exciting content!

Additional Tags and Keywords:

automated packaging, samosa packaging, packaging line animation, Aliya's Foods, advanced machinery, hygienic handling, precise sorting, efficient sealing, quality control

Hashtags:

#automatedpackaging #samosapackaging #packaginglineanimation #AliyasFoods #innovationinpackaging

Title: Automated Packaging Line Revolutionizes Samosa Production

Introduction:

In recent years, the demand for samosas has been on the rise globally. To meet this growing demand efficiently, manufacturers are turning towards automation to streamline their production processes. This article presents an innovative tilter for an automated packaging line that promises to revolutionize samosa production.

1. Increased Productivity:

The tilter in the automated packaging line plays a crucial role in optimizing the production process. By automatically tilting the samosas onto the packaging tray, it eliminates the need for manual labor, significantly increasing productivity. This results in a faster packaging process, allowing manufacturers to meet higher demand without compromising quality.

2. Enhanced Accuracy:

The tilter ensures precise placement of samosas onto the packaging tray, eliminating any human error caused by manual handling. This accuracy ensures all samosas are uniformly arranged, avoiding any inconsistencies in size, shape, or appearance. As a result, manufacturers can maintain a high standard of quality and presentation, meeting consumer expectations consistently.

3. Improved Efficiency:

With the integration of a tilter in the automated packaging line, manufacturers can achieve a higher level of operational efficiency. The tilter system is designed to work seamlessly with the rest of the packaging line, ensuring a smooth and continuous flow of samosas. This reduces downtime, minimizes bottlenecks, and maximizes overall production efficiency.

4. Cost Savings:

By automating the packaging process, manufacturers can reduce labor costs associated with manual handling and packaging. The tilter eliminates the need for dedicated workers to place samosas onto trays, leading to significant cost savings in the long run. Additionally, the automated system requires minimal maintenance, further reducing operational expenses.

5. Hygiene and Food Safety:

Maintaining hygiene and food safety standards is crucial in the food industry. The tilter in the automated packaging line is designed with food-grade materials, ensuring the sanitary handling of samosas. It minimizes the risk of contamination, as the samosas are untouched by human hands during the packaging process. This feature enhances consumer confidence in the product's safety and quality.

Conclusion:

The implementation of an automated packaging line with a tilter for samosas brings numerous advantages to manufacturers. Increased productivity, enhanced accuracy, improved efficiency, cost savings, and food safety are some of the key benefits. As the demand for samosas continues to grow, investing in such automated technology becomes essential for manufacturers to stay competitive and meet consumer expectations efficiently. Automatic Packing Line

#Automated #Packaging #Line #Samosas