Check out the leading manufacturer for professional coil packing solutions right here:

Title: Revolutionizing Case Packing with ABB IRB 1200 Robot: A Compact and Efficient Solution

Introduction:

In today's fast-paced manufacturing industry, automation plays a crucial role in streamlining processes and maximizing efficiency. A prime example of this is the utilization of robotic technology in case packing operations. This article will delve into the exciting world of a compact case packing cell that employs the ABB IRB 1200 robot, showcasing its capabilities, benefits, and its seamless integration with a used case packing machine. Join us as we explore how this innovative solution revolutionizes case packing operations.

Section 1: The ABB IRB 1200 Robot - Unleashing Efficiency

The ABB IRB 1200 robot is a true game-changer when it comes to robotic automation. With its compact design and high-speed operation, this robot is perfectly suited for case packing applications. Equipped with advanced technology and precise motion control, the IRB 1200 robot ensures optimal performance, accuracy, and reliability throughout the packing process.

Section 2: Seamless Integration with Used Case Packing Machine

To achieve a fully automated case packing solution, the ABB IRB 1200 robot seamlessly integrates with a used case packing machine. This combination offers a cost-effective solution for manufacturers who wish to upgrade their packaging operations without investing in new machinery. By leveraging the capabilities of both the robot and the machine, manufacturers can achieve enhanced productivity and reduced manual labor, resulting in significant cost savings.

Section 3: Unveiling the Operations

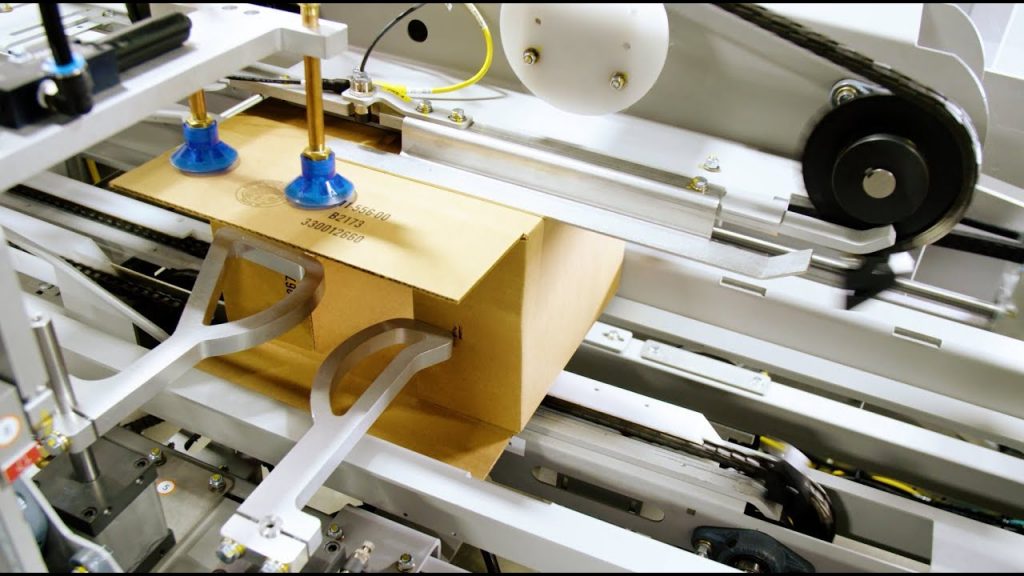

1. Opening the Case: The ABB IRB 1200 robot effortlessly opens the case, eliminating the need for manual intervention. Its precision grip and intelligent control ensure that the case is opened accurately and efficiently.

2. Jiggling and Adjusting: Once the case is open, the robot performs a jiggle and adjustment process to ensure that the contents are properly aligned within the case. This step guarantees that the packed products remain intact and secure during transportation.

3. Case Packing: With the utmost precision, the ABB IRB 1200 robot swiftly and accurately places the products inside the case. Its advanced vision system enables it to identify the correct positioning and orientation of the products, ensuring consistency and minimizing errors.

Section 4: Benefits of the Solution

1. Increased Efficiency: By automating the case packing process, manufacturers can achieve higher production rates, improved throughput, and reduced cycle times. The ABB IRB 1200 robot's speed and accuracy contribute to overall operational efficiency.

2. Enhanced Quality: The robot's precise movements and intelligent control ensure that each product is packed correctly, minimizing the risk of damage and ensuring consistent quality. This, in turn, leads to customer satisfaction and a positive brand image.

3. Cost Savings: Integrating the ABB IRB 1200 robot with a used case packing machine allows manufacturers to upgrade their packaging capabilities at a fraction of the cost of purchasing new equipment. Additionally, reduced labor costs and increased productivity contribute to significant long-term savings.

Conclusion:

The compact case packing cell utilizing the ABB IRB 1200 robot, in conjunction with a used case packing machine, presents a revolutionary solution for manufacturers seeking to optimize their packaging operations. By harnessing the power of automation, this innovative system offers increased efficiency, enhanced quality, and substantial cost savings. Embrace the future of case packing and explore the possibilities with the leading manufacturer for professional coil packing solutions today.

Check out the leading manufacturer for professional coil packing solutions right here: [Insert link to relevant product or service page] Case Packing Machine

"Efficient Robotic Solutions for Box Erecting, Case Packing, and Used Machinery"