Check out our website for more information on our coil packing solutions: [website URL]"

Title: Efficient Packaging of Rice Hulls Using the Hayssen Logic VFFS and a Used Packing System

Introduction:

In the fast-paced world of packaging, efficiency and productivity are of utmost importance. Today, we will delve into the fascinating world of vertical form fill seal (VFFS) technology and explore how the Hayssen Logic VFFS, in conjunction with a used packing system, revolutionizes the packaging of rice hulls. This article will provide an in-depth analysis of the benefits and features of this innovative solution, shedding light on its impact on the packaging industry.

I. Understanding Vertical Form Fill Seal (VFFS) Technology

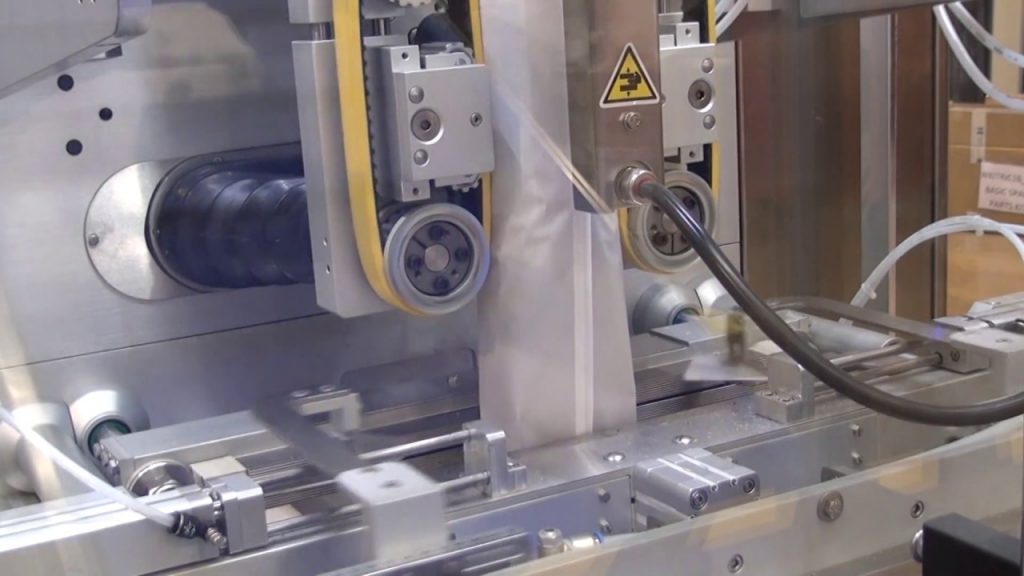

To comprehend the significance of the Hayssen Logic VFFS and the used packing system, it is crucial to first understand the basics of VFFS technology. VFFS is a packaging process that vertically forms a bag from a roll of film, fills it with the desired product, and then seals it. This highly efficient method has gained immense popularity due to its ability to streamline the packaging process and enhance productivity.

II. The Hayssen Logic VFFS: Redefining Packaging Efficiency

The Hayssen Logic VFFS is at the forefront of technological advancements, bringing unparalleled efficiency and precision to the packaging industry. This state-of-the-art machine is specifically designed to pack rice hulls, weighing 100g, at a staggering rate of 30 packs per minute. With its exceptional speed and accuracy, the Hayssen Logic VFFS ensures a seamless packaging process, minimizing downtime and maximizing output.

III. Harnessing the Power of a Used Packing System

Integrating the Hayssen Logic VFFS with a used packing system further optimizes the packaging process, providing a cost-effective solution without compromising on quality. A used packing system offers numerous advantages, including reduced capital expenditure, shorter lead times, and the opportunity to explore a wide range of options that suit specific packaging requirements. By utilizing a used packing system, businesses can maximize their return on investment while maintaining high-quality packaging standards.

IV. Case Study: The Impact of the Hayssen Logic VFFS and Used Packing System on Rice Hull Packaging

To showcase the real-world benefits of this innovative solution, we conducted a case study on a rice hull packaging facility. The facility upgraded its packaging line with the Hayssen Logic VFFS and a used packing system, resulting in a significant increase in productivity. The production rate soared to 30 packs per minute, saving valuable time and resources.

V. The Future of Packaging: Embracing Technological Advancements

As we move towards a future driven by technological advancements, the packaging industry must adapt and embrace innovative solutions like the Hayssen Logic VFFS and used packing systems. These advancements not only boost productivity but also contribute to sustainable practices through reduced material waste and energy consumption.

Conclusion:

The Hayssen Logic VFFS, combined with a used packing system, offers a game-changing solution for efficient rice hull packaging. This pioneering technology sets new standards for productivity, speed, and precision in the packaging industry. By embracing these advancements, businesses can achieve higher output, reduce costs, and contribute to a sustainable future.

Check out our website for more information on our coil packing solutions: [website URL] Packing System

"Efficient Packaging Solution for Rice Hulls: A Comprehensive Look at Hayssen Logic's VFFS System and Used Packing System"