Title: Advanced Food Packing Machines for Ready-to-Eat Meals | Retort Pouch Packing Solution

Description:

Introduction:

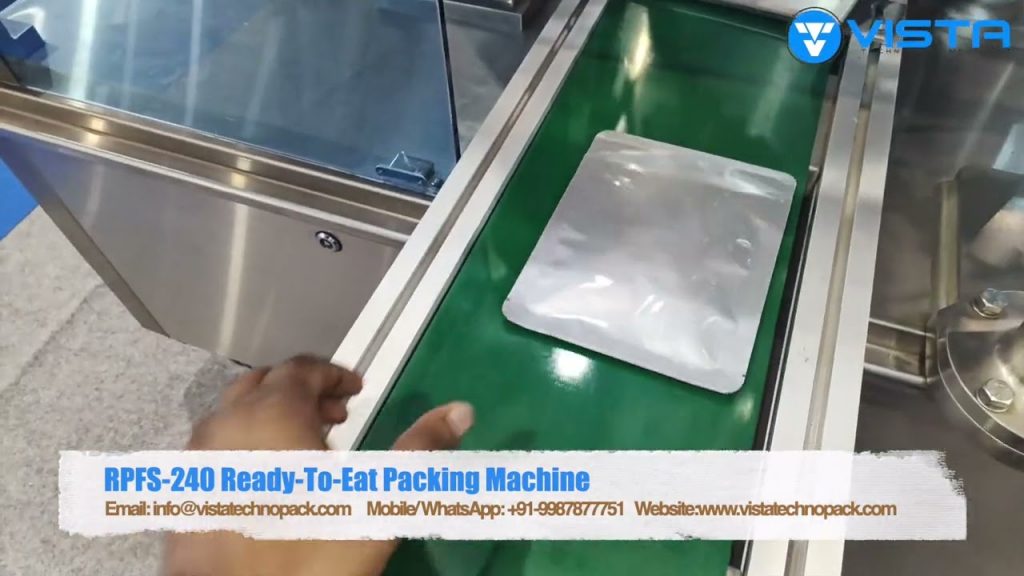

Experience the future of food packaging with our cutting-edge Food Packing Machine Manufacturer. Our innovative technology and expertise in producing top-quality Ready-to-Eat Packing Machines, Retort Packing Machines, and Retort Pouch Packing Machines have revolutionized the food packaging industry. In this video, we will delve into the features, benefits, and operation steps of our advanced machines, which are designed to meet the specific needs of food manufacturers.

Video Content:

Our Food Packing Machine Manufacturer offers a wide range of Ready-to-Eat Packing Machines that cater to the diverse requirements of the food industry. With our state-of-the-art technology, we ensure optimal efficiency, precision, and hygiene in the packaging process. Whether it's sealing, filling, or labeling, our machines excel in every aspect, providing seamless automation and reducing human errors.

Our Retort Packing Machines are specially designed for heat processing and sterilization of packaged food. With precise temperature control, these machines guarantee the safety and shelf life of your ready-to-eat meals. From soups and sauces to pre-packaged meals, our Retort Packing Machines ensure that your products stay fresh and delicious while meeting the highest industry standards.

Retort Pouch Packing Machines are ideal for packaging flexible and lightweight food items. These machines utilize advanced technology to create airtight and durable pouches that preserve the taste, texture, and nutritional value of your products. Our Retort Pouch Packing Machines are versatile and can handle various packaging formats, giving you the flexibility to meet market demands effectively.

Operation Steps:

1. Preparation: Ensure all necessary materials and ingredients are ready for packaging.

2. Machine Setup: Adjust the machine settings according to the packaging requirements.

3. Loading: Place the pre-packaged food items or pouches onto the conveyor belt.

4. Filling: The machine accurately fills the pouches with the desired quantity of food.

5. Sealing: The pouches are sealed using heat to ensure a secure and airtight packaging.

6. Sterilization (for Retort Packing Machines): The sealed pouches go through a heat processing and sterilization cycle to eliminate bacteria and extend shelf life.

7. Cooling and Inspection: The pouches are cooled down, and a thorough inspection is carried out to ensure quality control.

8. Labeling (optional): If required, the machine can add labels or stickers to the packaging.

9. Packaging Output: The finished packaged products are ready for distribution and sale.

Call to Action:

If you are a food manufacturer seeking advanced and reliable packing solutions, our Food Packing Machine Manufacturer is your perfect partner. Subscribe to our channel for more informative videos on food packaging technology. Like and share this video to spread the knowledge among your peers in the industry. For further inquiries, contact our team and let us assist you in choosing the ideal packing machine for your specific needs.

Additional Tags and Keywords: food packaging, packing machines, ready-to-eat meals, retort pouch, automation, food industry, heat processing, sterilization, sealing, filling, labeling, packaging formats.

Hashtags: #ReadytoEatPackingMachine #FoodPackingMachines #RetortPackingMachine #RetortPouchPackingMachine #FoodPackaging

Title: High-Quality Tilter for Ready to Eat Packing Machines: Revolutionizing the Retort Pouch Packing Process

Introduction:

In the fast-paced world of food production, efficiency and convenience are crucial elements for success. For manufacturers of Ready to Eat (RTE) products, investing in top-notch machinery is imperative. One such machine that has been transforming the industry is the Tilter for Ready to Eat Packing Machines. Designed specifically for Retort Packing and Retort Pouch Packing Machines, this innovative technology is redefining the packing process, ensuring superior quality and increased productivity. In this article, we will explore the benefits and features of this state-of-the-art tilter, revolutionizing the RTE packing industry.

1. Enhanced Efficiency:

The Tilter for Ready to Eat Packing Machines introduces a new level of efficiency by automating the process of tilting retort pouches. This eliminates the need for manual labor, reducing the risk of errors and ensuring consistent and accurate packing. With its high-speed operation, the tilter maximizes productivity, significantly reducing production time and costs.

2. Precise and Gentle Handling:

Retort pouches require delicate handling to preserve the integrity of the packed contents. The tilter's advanced technology ensures gentle tilting, preventing any damage to the pouches or compromising the quality of the RTE products. Its precise control system offers adjustable angles, enabling manufacturers to accommodate different product requirements and optimize packing efficiency.

3. Versatility and Adaptability:

Manufacturers in the RTE industry deal with a wide range of product sizes and shapes. The tilter boasts a versatile design that accommodates various retort pouch dimensions, making it suitable for diverse packing needs. Its adaptability allows manufacturers to switch between different packaging requirements seamlessly, minimizing downtime and maximizing flexibility.

4. Robust and Hygienic Construction:

The tilter is built to withstand the rigors of a demanding production environment. Constructed with high-quality materials, it ensures durability and longevity, reducing maintenance costs. Additionally, the tilter's design adheres to strict sanitary standards, featuring easy-to-clean surfaces and components, which ensure food safety and compliance with regulatory guidelines.

5. Integration and Connectivity:

To streamline the overall packing process, the tilter can be seamlessly integrated with existing Retort Packing Machines and Retort Pouch Packing Machines. Its user-friendly interface facilitates easy operation, and it can be synchronized with other automated systems, enhancing the overall efficiency of the production line.

Conclusion:

The Tilter for Ready to Eat Packing Machines represents a game-changing innovation in the RTE packing industry. With its enhanced efficiency, precise handling, versatility, and robust construction, this tilter empowers manufacturers to streamline their operations, increase productivity, and deliver high-quality RTE products consistently. By investing in this cutting-edge technology, manufacturers can stay ahead of the competition and meet the ever-growing demands of the modern food industry.Food Packing Machine

#Ready #Eat #Packing #Machine #Retort #Packing #Machine #Retort #Pouch #Packing #Machine #Manufacturers