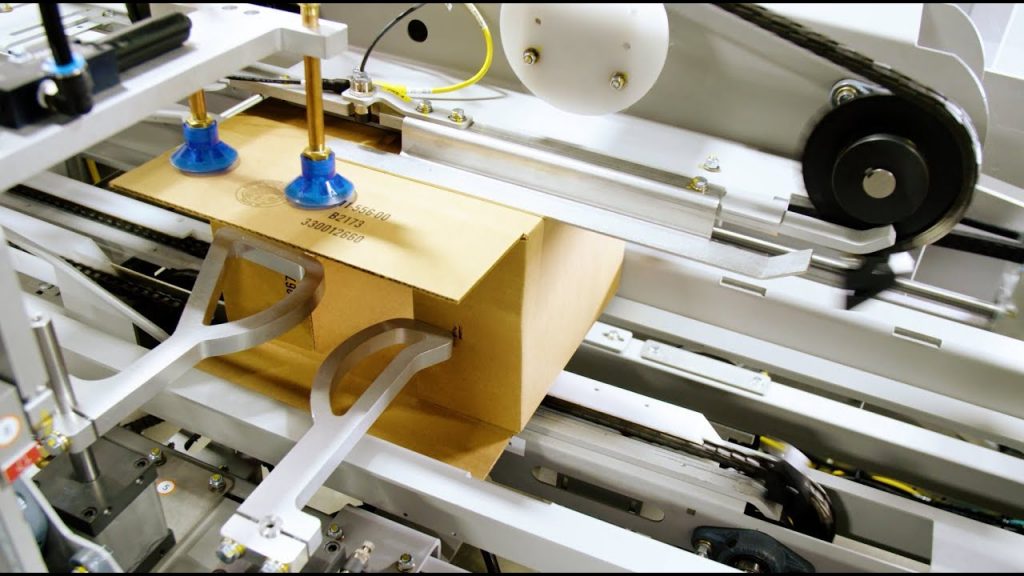

In this YouTube video, we will take a closer look at the efficient and reliable secondary packing machine used after the bottling line. Specifically, we will focus on the drop type case packing machine, which plays a crucial role in the packaging process. By highlighting the features and benefits of this equipment, we aim to provide a comprehensive understanding of its capabilities and how it contributes to the overall packaging operations.

The secondary packing machine, also known as the case packing machine, is an essential component in the packaging industry. Its primary function is to gather and arrange products, such as bottles, into cases or cartons for transport and storage. This automation process not only saves time and labor but also ensures consistent and secure packaging.

One of the key advantages of the drop type case packing machine is its versatility. It is capable of handling a wide range of products, including bottles of different shapes and sizes. This adaptability makes it an ideal choice for various industries, such as food and beverage, pharmaceuticals, and cosmetics.

Efficiency is another significant aspect of this equipment. The drop type case packing machine is designed to maximize productivity by achieving high-speed packing without compromising accuracy. With advanced technology and precision engineering, this machine ensures that products are neatly and securely packed, minimizing the risk of damage during transportation.

Furthermore, the drop type case packing machine offers user-friendly features that simplify operation and maintenance. Its intuitive interface allows operators to easily set up and adjust the machine according to specific packaging requirements. Additionally, the machine is designed for easy cleaning and maintenance, ensuring smooth and trouble-free operation.

To complete the packaging process, a carton sealing machine is often used in conjunction with the case packing machine. This machine efficiently seals the cartons, further securing the products inside. By utilizing both the case packing machine and carton sealing machine, manufacturers can streamline their packaging operations and enhance overall efficiency.

When it comes to selecting the right case packing equipment, it is crucial to choose a reliable and reputable manufacturer. Leading manufacturers in the industry offer a wide range of solutions tailored to specific packaging needs. They provide high-quality equipment that is built to last, ensuring long-term value and reliability.

In conclusion, the drop type case packing machine is an essential component in the secondary packaging process. Its versatility, efficiency, and user-friendly features make it an ideal choice for industries requiring high-speed and accurate packaging. By investing in reliable case packing equipment from a leading manufacturer, businesses can optimize their packaging operations and achieve professional packaging solutions.

Check out the leading manufacturer's coil packing solutions for professional packaging solutions here: Case Packing Machine

"Efficient and Reliable Packaging Solutions: Enhance Productivity with Advanced Secondary Packaging, Case Packing, Carton Sealing, and Equipment"