Industrial Paper Packer - Enhancing Efficiency with PLC and Touch Screen Control

Introduction:

In today's fast-paced industrial environment, optimizing packaging processes is vital for businesses to stay competitive. One such advancement is the integration of PLC (Programmable Logic Controller) and touch screen control in case packers. This technology not only enhances efficiency but also ensures safety with features like bottle alarm stop and no bottle no packing safety device. In this article, we will explore the benefits of using an Industrial Paper Packer equipped with these advanced functionalities.

Opinion/Thought Piece Style:

The integration of PLC and touch screen control in an Industrial Paper Packer marks a significant milestone in the packaging industry. This advanced technology offers numerous benefits that can revolutionize the way businesses pack their products.

Firstly, the PLC allows for precise control and automation of the packaging process. Gone are the days of manual adjustments and potential human errors. With the touch of a screen, operators can set parameters, customize packaging requirements, and monitor the entire process in real-time. This level of automation not only saves time but also eliminates the risk of human error, resulting in consistent and accurate packaging.

Furthermore, the bottle alarm stop feature adds an extra layer of safety to the packaging process. In the event of a bottle jam or misalignment, the system detects the issue and immediately halts the packing process. This prevents any potential damage to the bottles or the equipment, reducing downtime and costly repairs. The bottle alarm stop feature ensures that only properly aligned bottles are packed, maintaining the quality and integrity of the packaging.

Additionally, the no bottle no packing safety device is another valuable feature offered by the Industrial Paper Packer. This device ensures that the packing process only initiates when bottles are present. If no bottles are detected, the system automatically stops, preventing wasteful operations and avoiding damage to the equipment. This feature not only saves resources but also contributes to a more sustainable packaging process.

Case Study Style:

To illustrate the benefits of an Industrial Paper Packer equipped with PLC and touch screen control, let's consider a case study of a water bottle manufacturer. Prior to implementing this technology, the packaging process was time-consuming and prone to errors. The manual adjustments required for different bottle sizes often led to inconsistencies in packaging quality.

After adopting the Industrial Paper Packer with PLC and touch screen control, the manufacturer experienced a significant improvement in efficiency. The automation provided by the PLC eliminated the need for manual adjustments, resulting in consistent packaging quality across different bottle sizes. The touch screen control allowed operators to easily monitor and adjust parameters, further enhancing the efficiency of the packaging process.

Moreover, the bottle alarm stop feature proved invaluable in preventing bottle jams and misalignments. By immediately halting the packing process upon detection of an issue, the manufacturer could quickly resolve the problem without causing any damage to the bottles or the equipment. This resulted in reduced downtime and increased overall productivity.

The no bottle no packing safety device also played a crucial role in streamlining operations. The system automatically detected the absence of bottles and prevented wasteful operations. This not only saved resources but also contributed to a more sustainable packaging process.

In-depth Analysis Style:

The integration of PLC and touch screen control in an Industrial Paper Packer demonstrates the continuous advancements in the packaging industry. This technology offers unparalleled control, automation, and safety features that significantly enhance the efficiency of packaging processes.

The PLC ensures precise control and automation by eliminating manual adjustments and reducing the risk of human error. Operators can easily set parameters, customize packaging requirements, and monitor the process in real-time through the intuitive touch screen interface. This level of automation saves time, increases productivity, and ensures consistent packaging quality.

The bottle alarm stop feature adds an extra layer of safety to the packaging process. By immediately halting operations upon the detection of bottle jams or misalignments, the system prevents potential damage to the bottles and the equipment. This enhances overall reliability, reduces downtime, and minimizes maintenance costs.

Furthermore, the no bottle no packing safety device contributes to a more efficient and sustainable packaging process. By detecting the absence of bottles, the system prevents wasteful operations, conserves resources, and reduces the environmental impact of packaging processes.

Conclusion:

The integration of PLC and touch screen control in an Industrial Paper Packer offers numerous benefits, including enhanced efficiency, precise control, and improved safety. The automation provided by the PLC, coupled with features like the bottle alarm stop and no bottle no packing safety device, ensures consistent and reliable packaging. Businesses can optimize their packaging processes, increase productivity, and contribute to a more sustainable future.

Check the coil packing solution with a leading manufacturer for professional solutions just here: [Insert URL] Paper Packing Machine

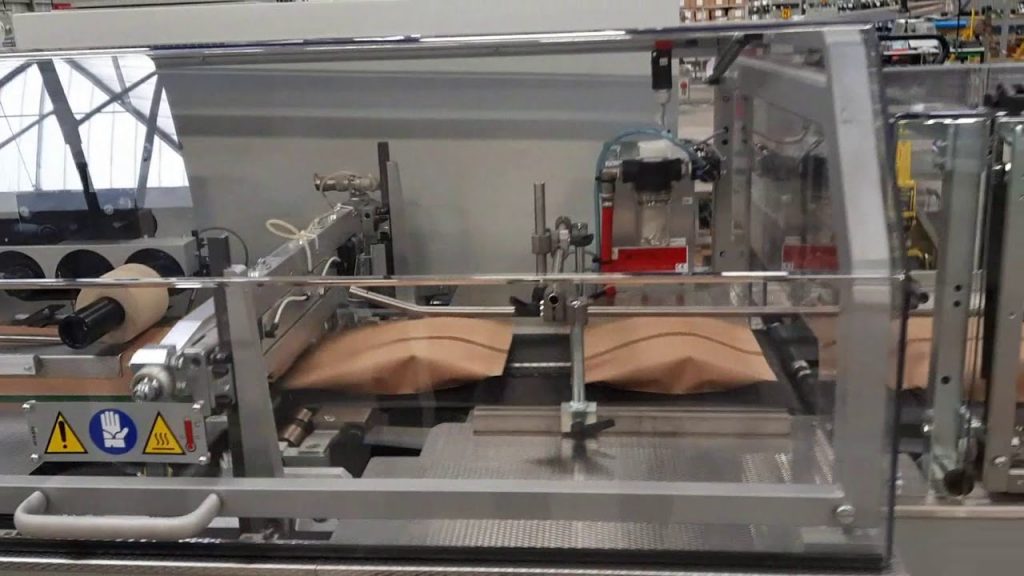

"Efficient Paper Packaging Solution for Water Bottles: Automatic Case Packer and Sealer Machine"