Introduction

In today's rapidly evolving world of technology, robots have become an integral part of various industries. They automate tasks, improve efficiency, and enhance productivity. One such revolutionary robot arm is the xArm 7, developed by UFactory, the creator of the popular desktop-sized uArm. In this article, we will delve into the functionalities and features of the xArm 7, an upcoming 7-axis robot arm that promises to revolutionize industrial automation.

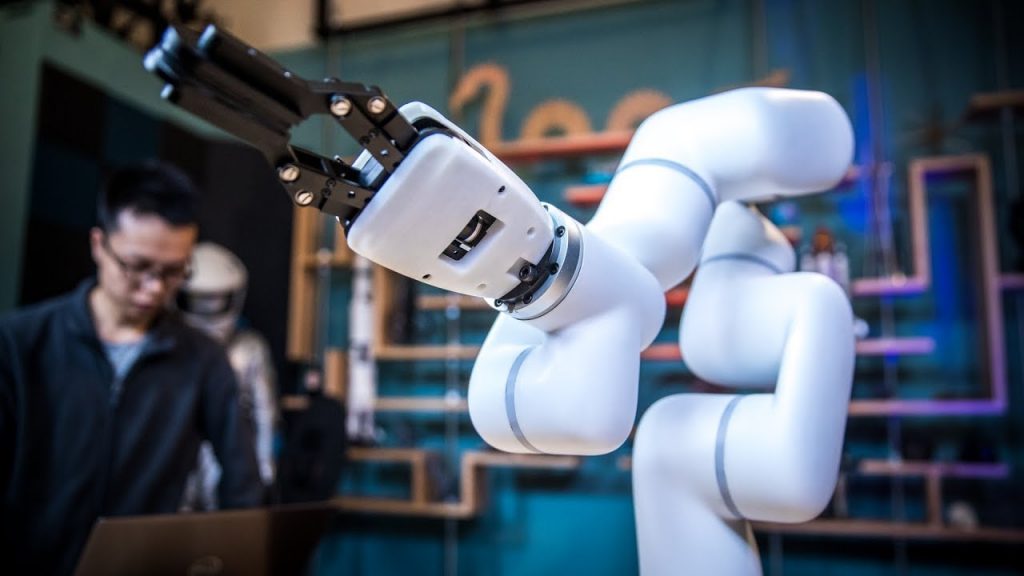

Meet the xArm 7: A Game-Changing Industrial Robotic Arm

The xArm 7 is a cutting-edge, programmable robot arm designed to cater to the needs of industrial automation. With its advanced capabilities and versatility, it has the potential to transform the way tasks are performed in various industries. Let's explore some of its notable features.

1. Seven-Axis Flexibility: Unlike traditional robot arms with limited range of motion, the xArm 7 boasts seven axes of movement, providing unparalleled flexibility and dexterity. This allows it to perform complex tasks with precision, making it suitable for a wide range of applications.

2. High Payload Capacity: The xArm 7 is engineered to handle heavy loads with ease. It has a remarkable payload capacity, enabling it to lift and manipulate objects weighing up to [insert weight capacity]. This makes it ideal for tasks that require strength and robustness.

3. User-Friendly Interface: UFactory has prioritized user experience by developing an intuitive interface for controlling the xArm 7. With its easy-to-use software, operators can effortlessly program the arm to perform specific tasks, reducing the need for extensive training and minimizing the learning curve.

4. Safety Features: Safety is a paramount concern in any industrial setting. The xArm 7 is equipped with advanced safety features to ensure the well-being of operators and those working alongside it. These features include collision detection, emergency stop buttons, and protective covers, making it a reliable and secure option for industrial automation.

5. Customizable End Effectors: The xArm 7 can be equipped with a variety of end effectors to suit different tasks. Whether it's gripping, welding, painting, or any other specialized application, the modular design of the xArm 7 allows for easy customization and adaptability.

6. Seamless Integration: The xArm 7 is designed to seamlessly integrate with existing industrial systems and workflows. This makes it a cost-effective solution for businesses looking to enhance automation capabilities without significant infrastructure changes.

The Future of Industrial Automation

With the introduction of the xArm 7, UFactory is setting a new standard in the field of industrial robotics. Its advanced features and capabilities have the potential to revolutionize various industries, including manufacturing, logistics, and healthcare.

As automation continues to evolve, the demand for intelligent and versatile robot arms like the xArm 7 will only increase. By streamlining processes, minimizing human error, and improving efficiency, these robotic arms have the ability to transform the way industries operate.

Conclusion

The xArm 7, developed by UFactory, is a game-changing industrial robotic arm that combines advanced technology, flexibility, and user-friendly features. With its seven-axis flexibility, high payload capacity, and customizable end effectors, it is poised to revolutionize industrial automation. As the world moves towards a more automated future, the xArm 7 is set to play a pivotal role in enhancing productivity and efficiency across various industries.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [insert relevant link or call-to-action] Industrial Robot

Introducing the Versatile and Programmable xArm 7: A Game-Changer in Industrial Robotics