Looking for a reliable and efficient Used Labeling Machine? Look no further than Solo Labeller Technology Sdn. Bhd., the leading labelling machine manufacturer in Malaysia. With their expertise in supplying top-quality labelling machines, Solo Labeller Technology is your go-to source for all your labelling needs.

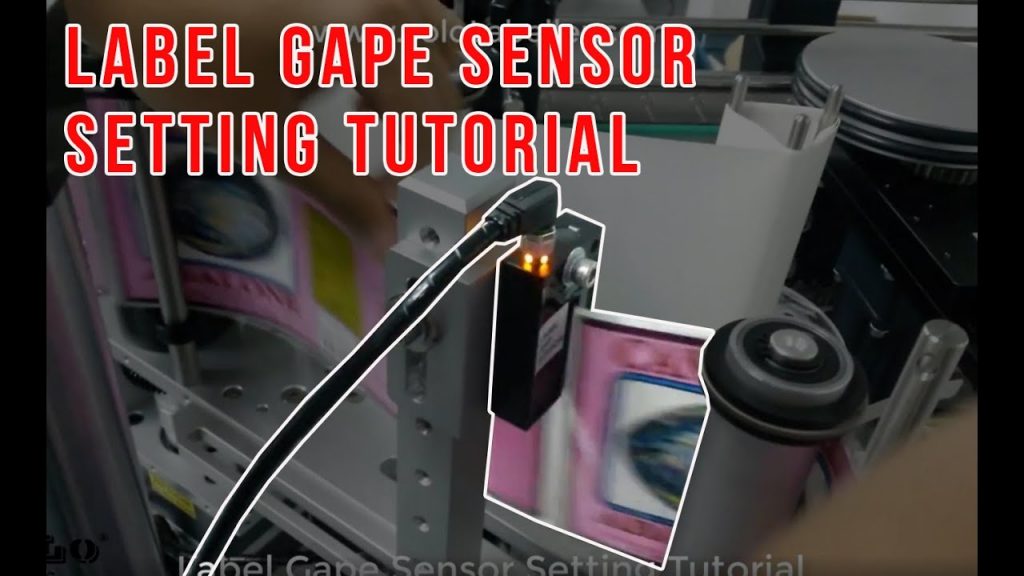

In this YouTube video article, we will explore the amazing features of Solo Labeller Technology's Used Labeling Machine and provide a tutorial on how to set up the Label Gap Sensor for optimal labelling results. Whether you are a small business owner or a large-scale manufacturer, this tutorial will help you understand the ins and outs of labelling machines and how to maximize their efficiency.

Title: Label Gap Sensor Setting | Labelling Machine Tutorial | Solo Labeller Technology

Introduction:

Welcome to Solo Labeller Technology's YouTube channel. In this tutorial, we will guide you through the process of setting up the Label Gap Sensor on your labelling machine for seamless and accurate labelling. Whether you are new to labelling machines or an experienced user, this tutorial will provide valuable insights to help you achieve the best results with your Used Labeling Machine.

Section 1: Understanding the Label Gap Sensor

Before we dive into the tutorial, let's first understand what a Label Gap Sensor is and why it is crucial for efficient labelling. The Label Gap Sensor is a key component of a labelling machine that detects the gap between labels, ensuring precise placement and preventing overlapping or misalignment. This sensor plays a vital role in achieving high-quality labels on your products.

Section 2: Step-by-Step Guide to Setting up the Label Gap Sensor

Now that we have a basic understanding of the Label Gap Sensor, let's move on to the step-by-step guide on how to set it up properly. Follow these instructions carefully to ensure optimal performance of your labelling machine:

Step 1: Locate the Label Gap Sensor

Step 2: Adjust the Sensor Position

Step 3: Calibrate the Sensor

Step 4: Test the Sensor Accuracy

Section 3: Troubleshooting Common Issues

Even with proper setup, labelling machines may encounter occasional issues. In this section, we will address some common problems you may encounter when using the Label Gap Sensor and provide troubleshooting tips to help you resolve them quickly.

Issue 1: Sensor Not Detecting Gap

Issue 2: Sensor Detecting Gap Incorrectly

Issue 3: Sensor Malfunctioning

Section 4: Benefits of Solo Labeller Technology's Used Labeling Machine

Now that you have a better understanding of the Label Gap Sensor and how to set it up, let's explore the benefits of choosing Solo Labeller Technology's Used Labeling Machine:

Benefit 1: Cost-effective Solution

Benefit 2: High-Quality Performance

Benefit 3: Reliable and Durable

Conclusion:

In this tutorial, we have covered the importance of the Label Gap Sensor in labelling machines and provided a step-by-step guide on how to set it up. We have also highlighted the benefits of choosing Solo Labeller Technology's Used Labeling Machine for your labelling needs. With their expertise and commitment to quality, Solo Labeller Technology is your trusted partner in achieving efficient and precise labelling solutions.

Check out Solo Labeller Technology's website for more information on their wide range of labelling machines and other innovative labelling solutions. Don't miss out on the opportunity to enhance your labelling processes with the leading manufacturer in the industry.

Remember, an accurately labeled product speaks volumes about your brand's professionalism and attention to detail. Invest in a reliable Used Labeling Machine today and take your labelling game to the next level with Solo Labeller Technology! Labeling Machine

"Optimizing Label Gap Sensor on Labelling Machine | Solo Labeller Tutorial: Enhancing Efficiency with Used Labeling Machine"