Welcome to our YouTube video on Used Labeling Machines! Thank you so much for checking it out. If you want more information on this topic, please visit our website to see more. Leave your comments and questions below, and we'll be happy to assist you.

In this video, we will discuss the importance of Used Labeling Machines and provide insights on how to adjust the Labeling Machine Sensor. Whether you're a sales engineer or someone interested in labeling machines, this video will provide valuable information.

Before we dive into the details, let's briefly explain what a Used Labeling Machine is. It refers to a machine that applies labels to various products or packages efficiently and accurately. These machines play a crucial role in industries such as food and beverage, pharmaceuticals, cosmetics, and many more.

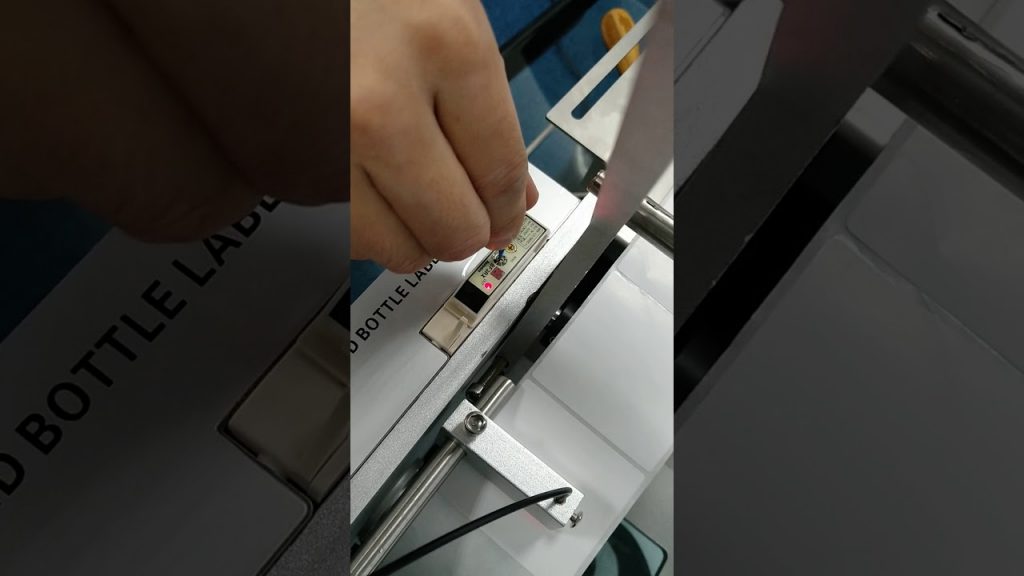

Now, let's move on to the topic of adjusting the Labeling Machine Sensor. The Sensor is a vital component of the machine that detects the position and orientation of the product or package. Proper adjustment of the Sensor ensures precise label placement, minimizing errors and wastage.

To adjust the Labeling Machine Sensor, follow these steps:

1. Start by understanding the type of Sensor your machine uses. There are different types, including optical sensors, ultrasonic sensors, and capacitive sensors. Each type has its own unique adjustment requirements.

2. Check the manufacturer's guidelines or user manual for specific instructions on adjusting the Sensor. This will vary depending on the make and model of your machine.

3. Make sure the Sensor is clean and free from any dirt or debris that could interfere with its operation. Clean it gently using a soft cloth or an appropriate cleaning solution.

4. Position the product or package in the correct orientation and ensure it is placed securely on the conveyor or labeling surface.

5. Gradually adjust the Sensor's sensitivity or threshold settings until it detects the product or package accurately. This may involve turning a dial, pressing buttons, or accessing the machine's control panel.

6. Test the machine by running a few labeling cycles. Observe the label placement and make any necessary adjustments to ensure it aligns perfectly with the product or package.

Remember, adjusting the Labeling Machine Sensor may require some trial and error. It's important to have patience and carefully monitor the results to achieve optimal performance.

Used Labeling Machines are a cost-effective solution for businesses looking to streamline their labeling processes. They offer the same functionality and efficiency as new machines but at a lower price point. By investing in a reliable used machine, you can save money without compromising on quality.

In conclusion, Used Labeling Machines are an essential tool for various industries. Understanding how to adjust the Labeling Machine Sensor is crucial to ensure accurate label placement. By following the steps we discussed, you can optimize the performance of your machine and improve overall efficiency.

We hope you found this video informative and helpful. If you have any further questions or need assistance, please feel free to reach out to us. Remember to check out our website for more information on Used Labeling Machines and other related topics. Thank you for watching!

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert Link to Manufacturer's Website] Labeling Machine

"Efficient Techniques for Adjusting Sensor on a Labeling Machine: A Comprehensive Guide to Operating Used Labeling Machines"