Plastic Injection Molding Machine - The Key to Efficient Mass Production

Plastic injection molding is a widely used method for manufacturing plastic parts in large quantities. It involves injecting molten plastic material into a mold cavity, allowing it to cool and solidify, and then ejecting the finished product. This process is highly efficient and provides consistent results, making it the preferred choice for many industries.

At its core, plastic injection molding requires the use of a reliable and high-quality plastic injection molding machine. These machines are designed to melt and inject plastic materials into molds, ensuring precise and repeatable production. In this article, we will explore the importance of plastic injection molding machines and how they contribute to mass production.

There are various types of plastic injection molding machines available in the market, each with its own unique features and capabilities. These machines come in different sizes, ranging from small tabletop models to large-scale industrial machines. The size and specifications of the machine depend on the specific requirements of the production process.

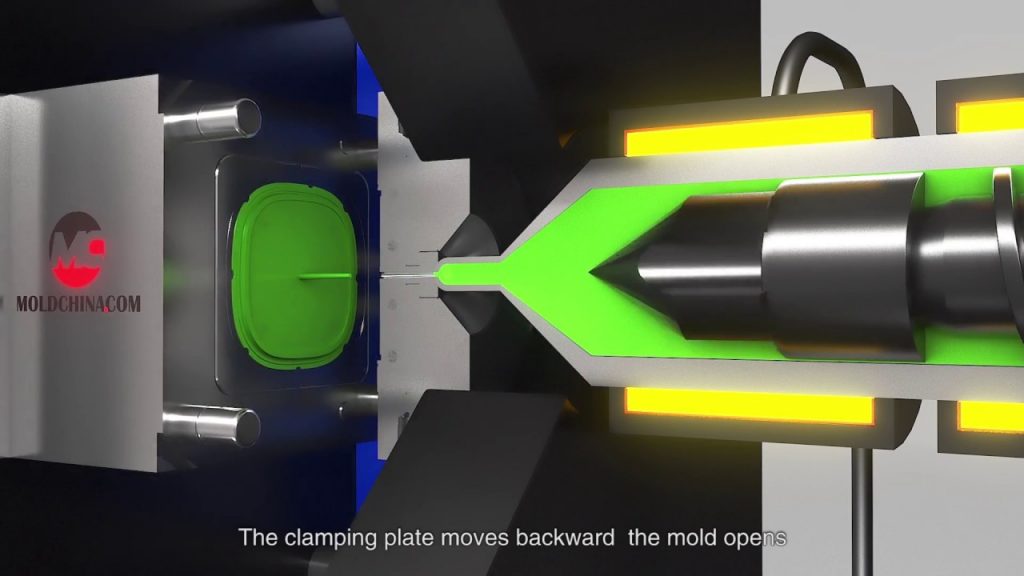

One of the key factors to consider when selecting a plastic injection molding machine is the clamping force it can provide. Clamping force refers to the force required to hold the mold closed during the injection process. It is crucial to have sufficient clamping force to ensure that the mold remains tightly shut, preventing any leaks or defects in the finished product.

Another important aspect is the injection unit of the machine. The injection unit is responsible for melting and injecting the plastic material into the mold. It consists of a screw or a plunger that pushes the molten plastic into the mold cavity. The design and performance of the injection unit directly affect the quality and precision of the final product.

Furthermore, the control system of the plastic injection molding machine plays a vital role in achieving optimal results. Advanced control systems allow for precise control of various parameters such as temperature, pressure, and injection speed. This level of control ensures consistent and high-quality production, reducing the risk of defects and rejections.

In recent years, technological advancements have led to the development of electric and hybrid plastic injection molding machines. These machines offer increased energy efficiency, reduced noise levels, and improved precision. They are becoming increasingly popular in the industry due to their environmental benefits and cost-effective operations.

In conclusion, plastic injection molding machines are the backbone of efficient mass production. They enable manufacturers to produce plastic parts with high precision, reliability, and consistency. The selection of the right machine, considering factors such as clamping force, injection unit, and control system, is crucial for achieving optimal results.

If you are looking for a reliable and professional solution for your plastic injection molding needs, consider partnering with leading manufacturers in the industry. Their expertise and experience will ensure that you get the most suitable plastic injection molding machine for your specific requirements. Check out their offerings today and unlock the potential of efficient mass production.

[Check the plastic injection molding machine solutions with leading manufacturers for professional guidance](link to relevant page) Plastic Injection Machine

"Mastering the Art of Plastic Injection Molding: Techniques, Machines, and Best Practices Unveiled!"