Check out the leading manufacturer of coil packing solutions for a professional solution here:

In this SEO-friendly YouTube video article, I will guide you on how to adjust the bag former and middle sealing of a Horizontal Bagging Machine. These two steps may seem challenging at first, but with the right instructions, you'll be able to master them in no time.

Adjusting the bag former and middle sealing is crucial for achieving efficient and effective packaging with a Horizontal Bagging Machine. By following these steps, you can ensure that your products are well-packaged and ready for distribution.

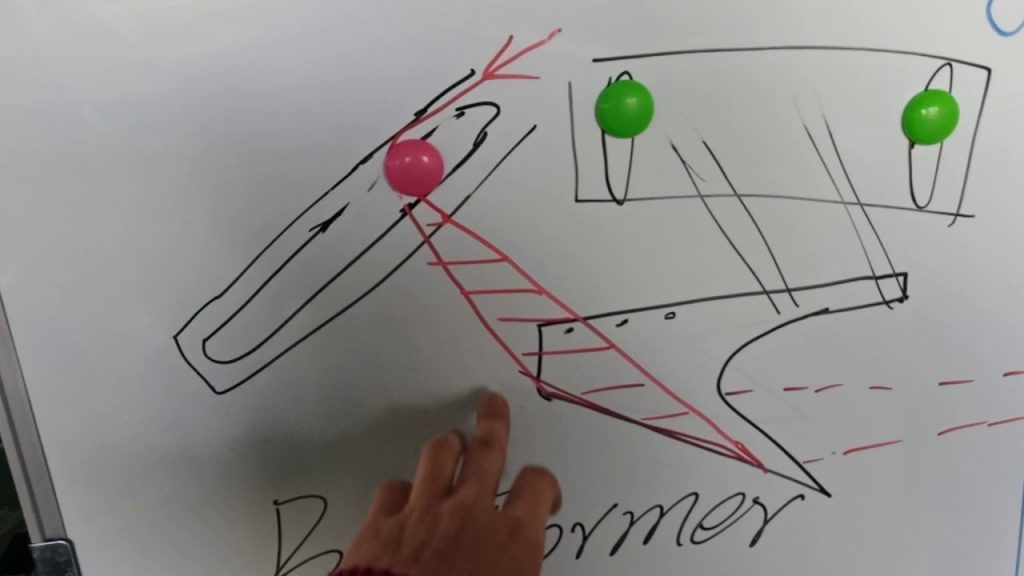

To begin, let's understand the importance of the bag former. The bag former is responsible for shaping the bags and ensuring they are formed accurately. Proper adjustment of the bag former is essential to avoid any wrinkles, folds, or misshapen bags.

Here's a step-by-step guide on how to adjust the bag former:

1. Start by loosening the screws that hold the bag former in place. This will allow you to make adjustments easily.

2. Carefully observe the bag former as the machine operates and identify any issues with bag formation.

3. Use the adjustment knobs or levers provided to make the necessary changes. These knobs or levers can typically be found on the sides or back of the machine.

4. Make small adjustments at a time and test the bag formation after each adjustment. This will help you identify the optimal settings for your specific packaging needs.

5. Once you have achieved the desired bag formation, tighten the screws to secure the bag former in place.

Now that you have successfully adjusted the bag former, let's move on to the middle sealing. The middle sealing is responsible for sealing the bags and ensuring they are airtight and secure.

Follow these steps to adjust the middle sealing:

1. Locate the middle sealing mechanism on your Horizontal Bagging Machine. This is typically located near the bag former.

2. Check the alignment of the middle sealing mechanism. It should be centered and parallel to the bag former.

3. If the alignment is off, use the adjustment knobs or levers provided to make the necessary changes. These knobs or levers can typically be found on the sides or back of the machine.

4. Make small adjustments at a time and test the sealing after each adjustment. This will help you achieve the perfect seal without any leaks or imperfections.

5. Once you have achieved the desired alignment and sealing quality, tighten any screws or bolts to secure the middle sealing mechanism in place.

By following these steps, you can effectively adjust the bag former and middle sealing of your Horizontal Bagging Machine. This will ultimately result in improved packaging quality and customer satisfaction.

Remember, practice makes perfect! Don't be discouraged if it takes a few attempts to get the adjustments just right. With time and experience, you'll become a pro at adjusting the bag former and middle sealing.

If you require further assistance or are interested in exploring more advanced packaging solutions, I recommend reaching out to industry-leading manufacturers. They can provide you with the expertise and professional solutions you need for your specific packaging requirements.

Check out the leading manufacturer of coil packing solutions for a professional solution here:

Remember, the key to successful packaging lies in mastering the art of adjusting the bag former and middle sealing of your Horizontal Bagging Machine. With the right techniques and a little bit of practice, you'll be able to achieve optimal packaging results every time. Bagging Machine

"Efficiently Adjusting the Horizontal Packing Machine for Pillow Bags: Bag Former and Middle Sealing Guide"