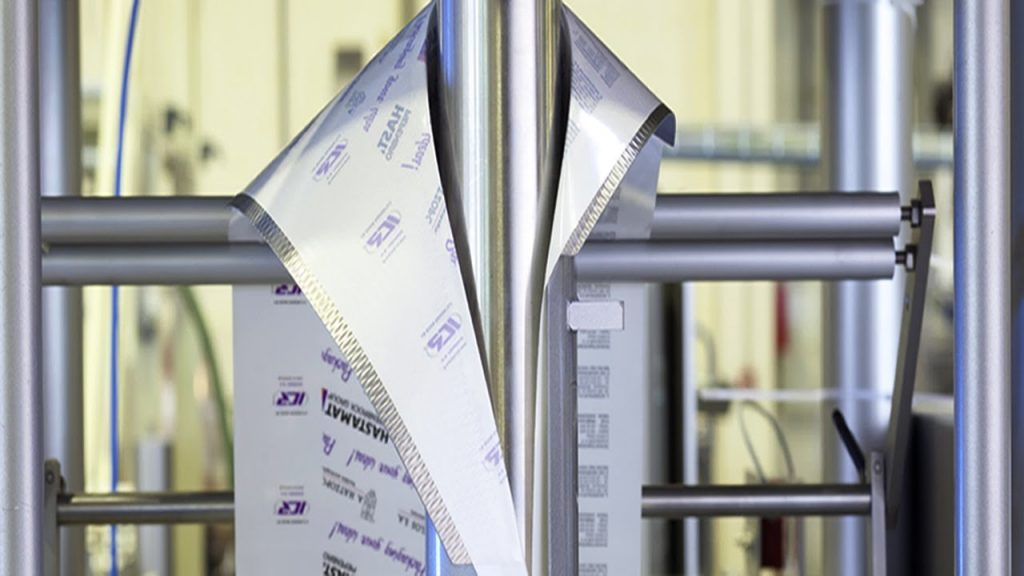

If you're in the market for a reliable and efficient packaging solution, look no further than the Vertical Form Fill Sealing Machine (VFFS). This automated assembly-line system is widely used in various industries to streamline product packaging processes.

The VFFS machine is designed to handle a wide range of products, from powders and liquids to granules and solid items. Its versatility makes it a popular choice for manufacturers looking to optimize their packaging operations. With its automated functionality, the VFFS machine can significantly reduce labor costs and increase productivity.

One of the key components of the VFFS machine is the filling packing machinery. This is responsible for accurately measuring and filling the product into the packaging material. In particular, the volumetric cups play a crucial role in achieving precise filling measurements.

Adjusting the volumetric cups for the filling packing machinery requires careful calibration. This ensures that the correct amount of product is dispensed into each package. Here's a step-by-step guide on how to adjust the volumetric cups for your filling packing machinery:

1. Start by identifying the type of product you'll be packaging. Different products have different densities and flow characteristics, which can affect the accuracy of the filling process.

2. Consult the user manual or contact the manufacturer for specific instructions on adjusting the volumetric cups. They will be able to provide you with the necessary information based on your product requirements.

3. Once you have the instructions, locate the adjustment mechanism for the volumetric cups. This is typically a screw or knob that allows you to modify the cup size.

4. Begin by setting the machine to its lowest setting. This will ensure that no product is being dispensed during the adjustment process.

5. Gradually increase the size of the volumetric cups while running the machine. Observe the filling measurements and make adjustments as necessary. The goal is to achieve the desired fill volume without over or underfilling the packages.

6. Test the packaging process with a few sample products. Check the weight or volume of the filled packages to ensure they meet your specifications.

7. Fine-tune the adjustments if needed. Keep in mind that different products may require different settings, so it's important to carefully monitor the filling process and make necessary modifications.

By following these steps, you'll be able to adjust the volumetric cups for your filling packing machinery and ensure accurate and consistent product packaging.

In conclusion, the Vertical Form Fill Sealing Machine (VFFS) with its efficient filling packing machinery is a game-changer for manufacturers in need of a reliable packaging solution. Whether you're packaging powders, liquids, granules, or solid items, the VFFS machine can streamline your operations and improve productivity. Remember to calibrate the volumetric cups correctly for precise filling measurements.

Check the coil packing solution with a leading manufacturer for a professional solution tailored to your specific needs. Filling Packing Machine

"Optimizing Granules Packaging Machine: Mastering Volumetric Cup Adjustments for Efficient Filling and Packing Process"