Title: Efficient Industrial Packing Line and Robotic Palletizing System

Description:

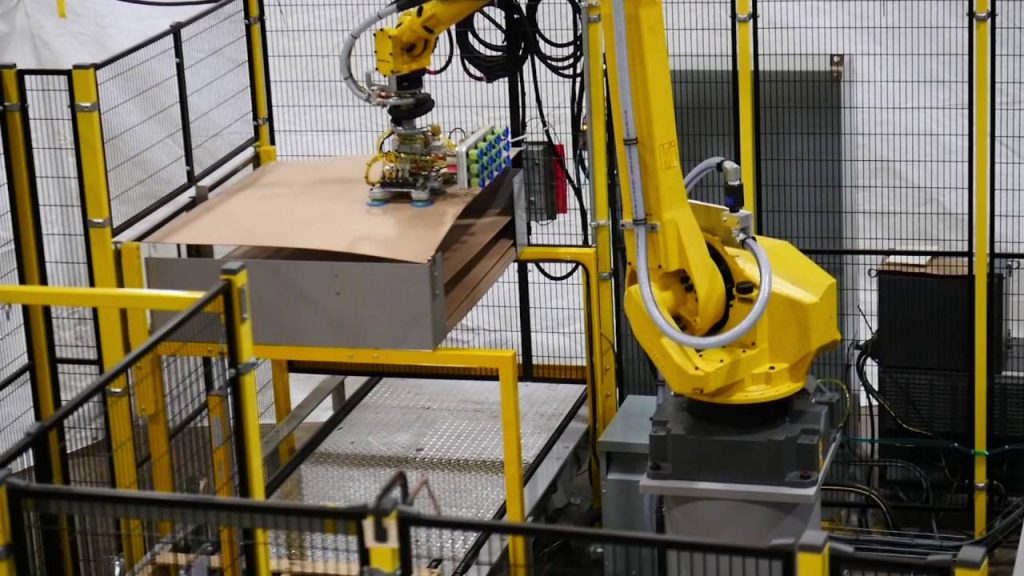

Welcome to our video showcasing the exceptional Industrial Packing Line, End-of-Line Robotic Case Packer & Palletizer - Schneider Packaging & Robotic Packing & Palletizing System. This cutting-edge system, provided by FANUC, revolutionizes the packaging and palletizing process for various industries.

Introduction:

In this video, we present a comprehensive overview of the Industrial Packing Line, End-of-Line Robotic Case Packer & Palletizer - Schneider Packaging & Robotic Packing & Palletizing System. With its advanced features and capabilities, this system ensures streamlined and efficient packaging operations.

Video Content:

This video covers the key points and highlights of the Industrial Packing Line & Robotic Palletizing System. It showcases the system's advanced robotic technologies, precise case packing capabilities, and efficient palletizing functions. The video provides a step-by-step demonstration of the system's operation, highlighting its speed, accuracy, and versatility.

Key Features and Benefits:

- Automated Case Packing: The Industrial Packing Line incorporates state-of-the-art robotic technology to handle the packing process with utmost precision and efficiency. It eliminates the need for manual labor, reducing errors and improving productivity.

- Flexible Palletizing Options: The End-of-Line Robotic Palletizer offers versatile palletizing solutions for various product types and sizes. It automatically arranges the cases onto pallets, optimizing space utilization and ensuring secure transportation.

- Seamless Integration: Schneider Packaging & Robotic Packing & Palletizing System seamlessly integrates with existing production lines, ensuring a smooth transition and minimal disruption to your operations.

- Increased Productivity: With its high-speed capabilities and intelligent software, this system significantly enhances productivity by reducing cycle times and maximizing throughput.

- Improved Safety: The system's advanced safety features and sensors ensure a safe working environment for operators and reduce the risk of accidents or injuries.

Call to Action:

If you found this video informative and valuable, please consider liking, subscribing, and sharing it with your colleagues and industry peers. Stay updated with the latest advancements in industrial packaging and palletizing systems by following our channel.

Additional Tags and Keywords:

Industrial Packing Line, Robotic Case Packer, Palletizer, Schneider Packaging, Robotic Packing, Palletizing System, FANUC, packaging automation, end-of-line solutions, robotic technologies, efficient case packing, versatile palletizing, increased productivity, seamless integration, advanced safety features.

Hashtags: #IndustrialPackingLine #RoboticPalletizer #PackagingAutomation #EfficientCasePacking #PalletizingSystem #FANUC

Title: Enhancing Efficiency: Tilter for End-of-Line Robotic Case Packer & Palletizer - Schneider Packaging

Introduction:

In the ever-evolving landscape of industrial automation, Schneider Packaging has emerged as a leading provider of innovative solutions. Their End-of-Line Robotic Case Packer & Palletizer system has revolutionized packaging and palletizing processes. To further enhance the efficiency and versatility of this system, the integration of a tilter can provide immense benefits. This article explores the advantages and features of a tilter for Schneider Packaging's End-of-Line Robotic Case Packer & Palletizer.

1. Maximizing Space Utilization:

One of the primary advantages of incorporating a tilter into the system is the optimization of space utilization. By tilting cases or products at specific angles, the tilter allows for more efficient stacking and placement on pallets. This maximizes the available space, thus reducing the number of pallets required and minimizing storage costs.

2. Improved Stability and Load Integrity:

The tilter ensures better stability and load integrity during the palletizing process. By tilting cases onto the pallets at the desired angle, it prevents the products from sliding or shifting during transportation. This results in safer and more secure packaging, reducing the risk of damage or product loss.

3. Flexibility in Packaging Design:

The tilter for Schneider Packaging's system offers unparalleled flexibility in packaging design. It allows for the precise adjustment of case angles, enabling the creation of unique patterns or configurations on pallets. This flexibility is particularly beneficial for industries with irregularly shaped or fragile products that require specific orientation or positioning.

4. Seamless Integration with Robotic System:

The tilter seamlessly integrates with Schneider Packaging's End-of-Line Robotic Case Packer & Palletizer. Its compatibility and synchronization with the existing robotic system ensure smooth operation and minimal downtime during installation. The tilter can be easily programmed to work in tandem with the robotic arm, allowing for precise and efficient case tilting and palletizing.

5. Enhanced Ergonomics and Worker Safety:

By automating the tilting process, the tilter eliminates the need for manual labor to adjust case angles or stack pallets. This significantly reduces the risk of musculoskeletal injuries for workers, enhancing overall workplace safety. Additionally, the tilter's user-friendly interface and intuitive controls make it easy to operate, minimizing human error and enhancing ergonomics.

Conclusion:

The integration of a tilter with Schneider Packaging's End-of-Line Robotic Case Packer & Palletizer system offers numerous benefits, including optimized space utilization, improved stability, flexibility in packaging design, seamless integration, and enhanced ergonomics. By investing in this innovative solution, businesses can further streamline their packaging processes, achieve higher productivity, and maintain a competitive edge in the market. Automatic Packing Line

#EndofLine #Robotic #Case #Packer #Palletizer #Schneider #Packaging