Check out our website for the best industrial robot technology solutions."

Title: Enhancing Industrial Robot Toolpaths with Error-Free Software

Introduction:

In today's fast-paced industrial landscape, precision and efficiency are key factors that determine the success of any manufacturing process. Industrial robot technology has revolutionized the way we manufacture products, allowing us to automate complex tasks with ease. However, ensuring error-free toolpaths for these robots can be a challenging task. This article will explore the importance of using the right software to generate toolpaths that are free from errors, according to experts at Battelle.

Industrial Robot Technology: Enhancing Efficiency and Precision

Industrial robot technology has come a long way in improving the efficiency and precision of manufacturing processes. These robots can perform repetitive tasks with great accuracy, reducing the risk of human error and enhancing overall productivity. However, to achieve optimal performance, it is essential to have error-free toolpaths that guide the robots' movements.

The Role of Software in Generating Error-Free Toolpaths

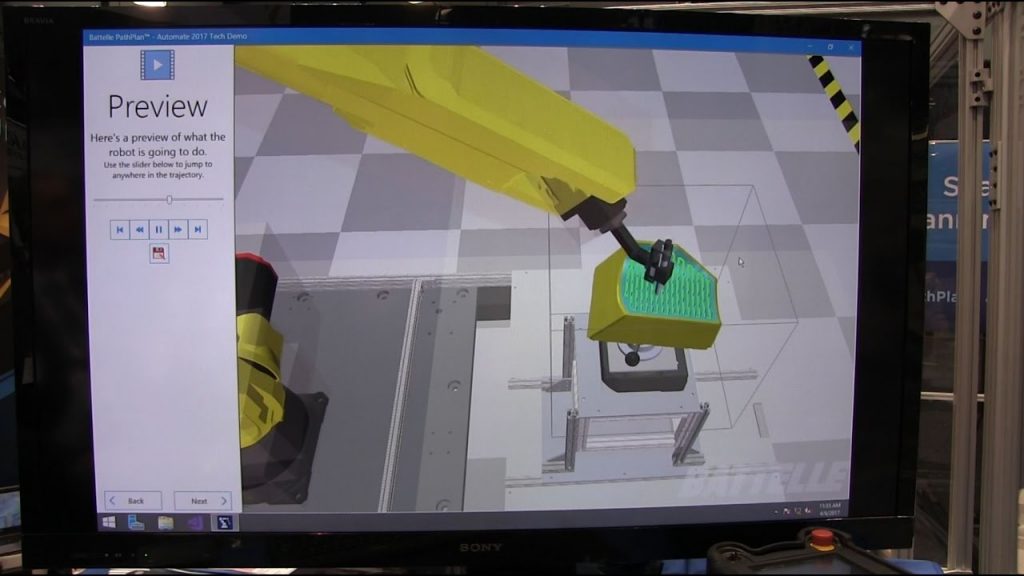

One of the crucial aspects of industrial robot technology is the software that generates toolpaths. Toolpaths are the precise instructions that guide the robot's movements, dictating the path it takes and the actions it performs. Any errors in these toolpaths can lead to costly mistakes and inefficiencies in the manufacturing process.

Battelle Expert Insights: The Right Software for Error-Free Toolpaths

According to experts at Battelle, choosing the right software is crucial in generating error-free toolpaths for industrial robots. The software needs to be capable of analyzing complex data, such as 3D scanning results, and converting it into precise toolpaths that the robot can follow.

By utilizing advanced algorithms and machine learning techniques, this software can optimize toolpaths, minimizing the risk of collisions, reducing cycle times, and maximizing efficiency. It enables manufacturers to achieve higher precision, better quality control, and increased productivity.

Case Study: Industrial Robot Toolpaths with 3D Scanning

To further understand the significance of error-free toolpaths, let's consider a case study involving industrial robot technology and 3D scanning. With the integration of 3D scanning technology, manufacturers can capture detailed information about the objects being manufactured. This information can then be used to generate accurate toolpaths for the robots.

The software analyzes the 3D scanning data and creates toolpaths that take into account the shape, size, and intricacies of the object. This ensures that the robot follows the most efficient and precise path, reducing material waste and improving overall production quality.

Conclusion: Unlocking the Potential of Industrial Robot Technology

In today's competitive manufacturing industry, the right software plays a crucial role in unlocking the full potential of industrial robot technology. By generating error-free toolpaths, manufacturers can enhance efficiency, precision, and productivity. With advancements in technology, such as 3D scanning integration, the possibilities for optimizing toolpaths are endless.

To explore the vast capabilities of industrial robot technology and find the best solutions for your manufacturing needs, we invite you to visit our website. Our team of experts is dedicated to providing you with the latest advancements in industrial robot technology, ensuring error-free toolpaths and maximizing your production efficiency.

Check out our website for the best industrial robot technology solutions. Industrial Robot

"Mastering Programming Industrial Robot Toolpaths with 3D Scanning and Advanced Robotics Techniques"