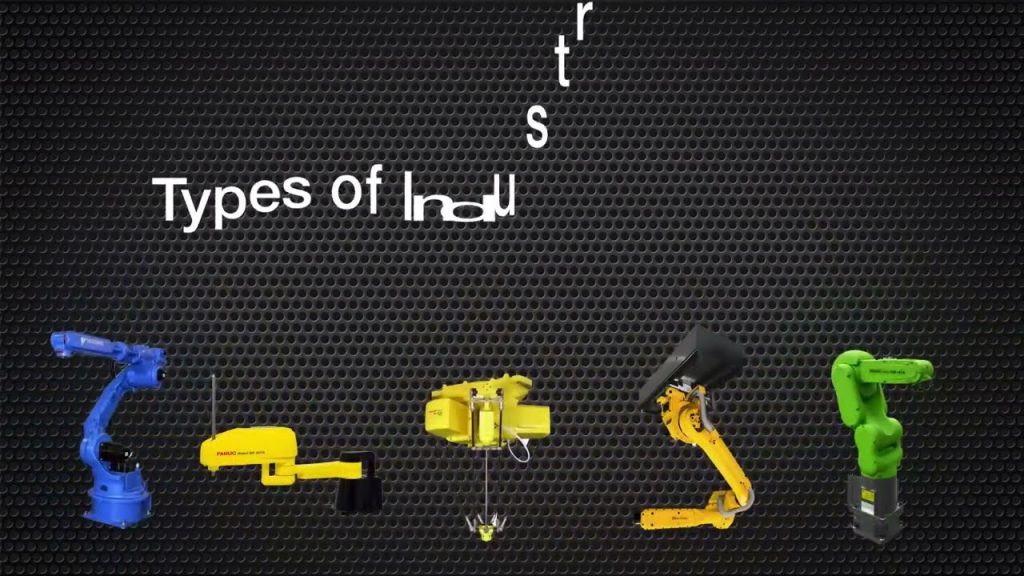

Types of Industrial Robots

Robots have revolutionized the industrial sector, enhancing productivity, efficiency, and safety. They are designed for a wide range of applications and come in various types, each with its own unique features. In this article, we will discuss the different types of industrial robots and the specific features that set them apart.

1. SCARA Robots:

SCARA robots, also known as Selective Compliance Assembly Robot Arms, are widely used in assembly and material handling tasks. These robots have a horizontal reach and are designed to work in a fast-paced production line. SCARA robots are known for their high degree of accuracy and repeatability, making them ideal for applications that require precision.

2. Cartesian Robots:

Cartesian robots, also called gantry robots, are characterized by their Cartesian coordinate system. These robots use linear motion to move along three axes (X, Y, and Z). Cartesian robots are commonly used in pick-and-place operations and are known for their strong and precise movements. They are often utilized in industries such as packaging, material handling, and machine loading.

3. Articulated Robots:

Articulated robots have a similar structure to the human arm with multiple joints, providing them with a high degree of freedom. These robots are versatile and can be used in various applications, such as welding, painting, and assembly. Articulated robots are known for their flexibility and agility, allowing them to perform complex tasks in tight spaces.

4. Delta Robots:

Delta robots, also known as parallel robots, are designed for high-speed pick-and-place operations. These robots consist of a series of interconnected links and are commonly used in industries such as food and beverage, pharmaceuticals, and electronics. Delta robots are known for their exceptional speed and precision, making them ideal for applications that require rapid and accurate movements.

5. Collaborative Robots:

Collaborative robots, or cobots, are designed to work alongside humans, enhancing productivity and safety. These robots are equipped with advanced sensors and software that allow them to interact and collaborate with humans in a shared workspace. Cobots can be used in various applications, such as assembly, packaging, and quality control. They are known for their ease of use and flexibility, as they can be easily programmed and reprogrammed for different tasks.

In conclusion, the industrial robot market offers a wide range of options to suit various applications and industries. SCARA robots excel in precision tasks, Cartesian robots are ideal for pick-and-place operations, articulated robots offer flexibility and agility, delta robots are designed for high-speed operations, and collaborative robots enhance productivity and safety in shared workspaces.

Check the coil packing solution with leading manufacturers for a professional solution just here. Industrial Robot

"Exploring the Diversity of Industrial Robots: A Comprehensive Guide to Efficient Automation Processes"