Introduction

In today's highly competitive dairy industry, efficiency and precision are crucial factors for success. One of the key processes in this industry is the palletizing of yogurts, where the Stäubli TX200 6-axis robots at Bohemilk in the Czech Republic have proven to be an invaluable asset. In this article, we will explore the industrial robot applications for palletizing in the dairy industry and how the Stäubli robots have revolutionized the process at Bohemilk.

Industrial Robot Applications: Palletizing in the Dairy Industry

Palletizing is the process of stacking and arranging products on pallets for transportation and storage. In the dairy industry, palletizing is a critical step that ensures the safe and efficient handling of yogurt glasses. Traditionally, this process was performed manually, which was time-consuming and prone to human error. However, with the advancements in robotics technology, the use of industrial robots for palletizing has become increasingly common.

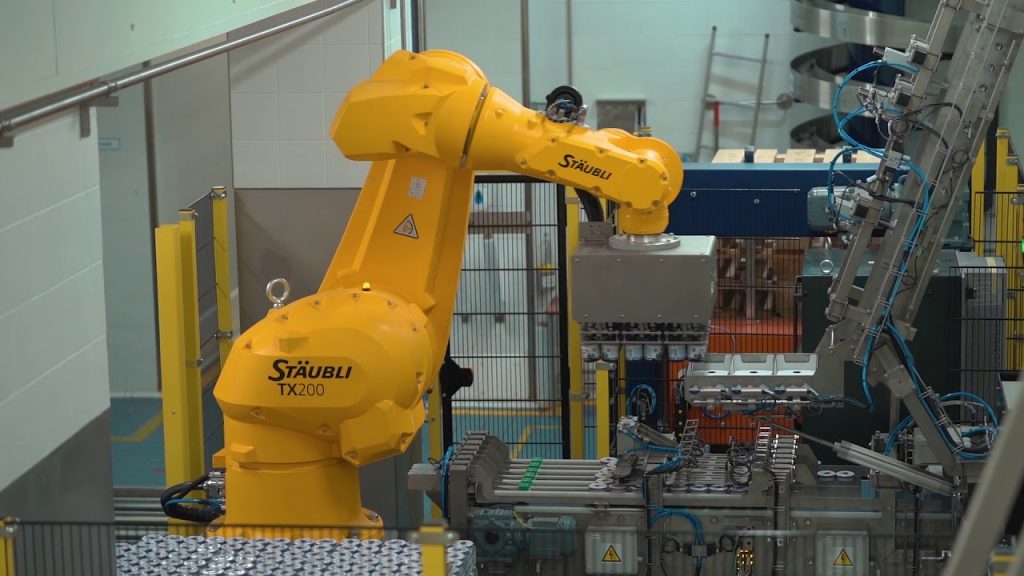

The Stäubli TX200 6-axis robots have emerged as a preferred choice for palletizing applications in the dairy industry. These robots offer exceptional precision, speed, and flexibility, making them ideal for handling delicate glass containers filled with yogurt. At Bohemilk, three parallel lines of Stäubli robots have been deployed to streamline the palletizing process and improve overall efficiency.

Case Study: Bohemilk and Stäubli TX200 Robots

Bohemilk, a leading dairy company based in the Czech Republic, recognized the need for automation in their palletizing process to keep up with the growing demand for their products. They turned to Stäubli and their TX200 robots for a solution that would meet their specific requirements.

The Stäubli TX200 robots at Bohemilk are equipped with advanced vision systems that allow them to accurately detect and pick up yogurt glasses from the production line. The robots then stack the glasses in an organized manner on pallets, ensuring stability and minimizing the risk of breakage. This automated process eliminates the need for manual handling, reducing the risk of product contamination and improving overall product quality.

The Stäubli robots' 6-axis design gives them the flexibility to handle various palletizing patterns and adapt to different packaging sizes. This versatility has been instrumental in accommodating Bohemilk's diverse product range and production needs. The robots can easily switch between different lines and adapt to changes in production volume, ensuring optimal efficiency and minimizing downtime.

The integration of Stäubli robots at Bohemilk has resulted in significant improvements in productivity and operational efficiency. The automated palletizing process has reduced labor costs and increased throughput, allowing Bohemilk to meet customer demands more effectively. The robots' precision and accuracy have also led to a decrease in product wastage and breakage, further enhancing overall profitability.

Conclusion

The use of industrial robots for palletizing applications in the dairy industry, such as the Stäubli TX200 6-axis robots at Bohemilk, has revolutionized the way yogurt glasses are handled and stacked. These robots offer unmatched precision, speed, and flexibility, resulting in improved productivity, efficiency, and product quality.

As the demand for dairy products continues to rise, it is crucial for companies in the industry to embrace automation and leverage the benefits of industrial robot applications for palletizing. The success story of Bohemilk and their integration of Stäubli robots serves as a testament to the transformative power of robotics in the dairy industry.

Check the palletizing solution with leading manufacturers for professional solutions. Industrial Robot

"Optimizing Dairy Production with Industrial Robots: Enhancing Palletizing Processes for the Dairy Industry"