Plastic Injection Machine: Revolutionizing the Manufacturing Industry

Introduction

Plastic injection molding is a widely used technique in the manufacturing industry. It involves injecting molten plastic material into a mold cavity, allowing it to cool and solidify into the desired shape. With the help of advanced technology, the process has become more efficient and cost-effective, making plastic injection machines an indispensable tool for many businesses. In this article, we will explore the benefits and applications of plastic injection machines, as well as the importance of injection mold testing.

The Evolution of Plastic Injection Machines

Plastic injection machines have come a long way since their inception. From manual operation to fully automated systems, these machines have revolutionized the manufacturing industry. The introduction of computer numerical control (CNC) technology has significantly improved the precision and repeatability of the injection molding process. This has led to higher quality products, reduced waste, and increased productivity.

Applications of Plastic Injection Machines

Plastic injection machines find applications in various industries, including automotive, electronics, medical, and consumer goods. The versatility of these machines allows manufacturers to produce a wide range of products, from small intricate components to large structural parts. Some common applications include:

1. Automotive Industry: Plastic injection machines are used to produce various components for automobiles, such as bumpers, dashboards, and interior trims. The ability to mold complex shapes and integrate multiple functionalities makes plastic injection molding the preferred choice for many automotive manufacturers.

2. Electronics Industry: The electronics industry relies heavily on plastic injection machines to produce components like housings, connectors, and switches. These machines offer high precision and consistency, ensuring that the final products meet the strict requirements of the electronics industry.

3. Medical Industry: Plastic injection machines play a vital role in the production of medical devices and equipment. From syringes to surgical instruments, these machines enable manufacturers to produce sterile, high-quality products that are crucial for healthcare professionals and patients.

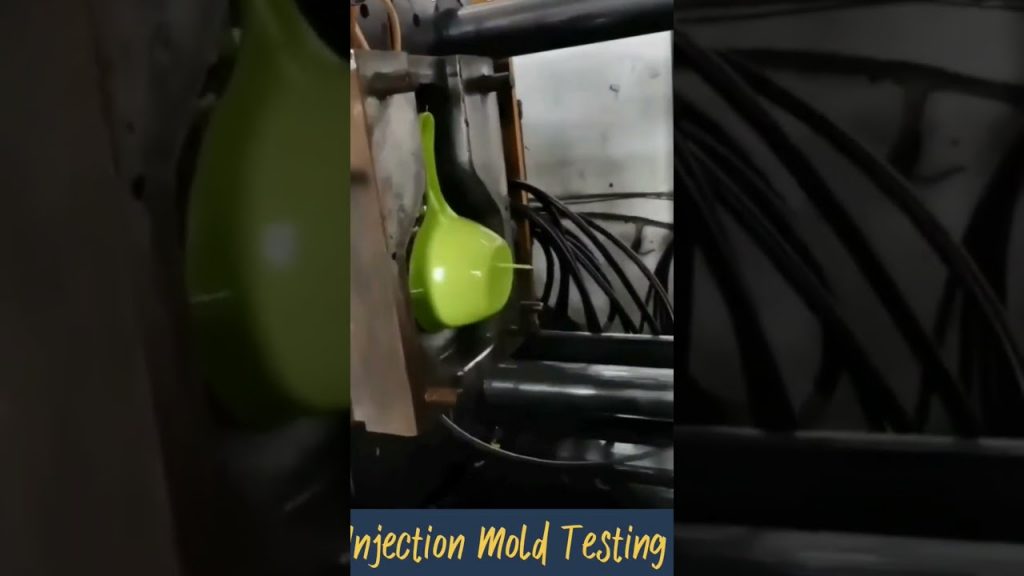

Importance of Injection Mold Testing

Injection mold testing is a crucial step in the plastic injection molding process. It involves evaluating the mold design, material flow, and overall functionality of the mold. By conducting thorough testing, manufacturers can identify and address any issues or defects before mass production. This helps to minimize costly rework, reduce production downtime, and ensure the final product meets the required specifications.

Conclusion

Plastic injection machines have revolutionized the manufacturing industry, offering a cost-effective and efficient solution for producing high-quality plastic products. The advancements in technology have made these machines more precise, reliable, and versatile than ever before. Injection mold testing plays a crucial role in ensuring the success of the injection molding process, enabling manufacturers to deliver products that meet the highest standards.

Whether you are in the automotive, electronics, medical, or any other industry, investing in a plastic injection machine can streamline your production process and help you stay competitive in today's fast-paced market. Check out leading manufacturers for professional solutions and unlock the full potential of plastic injection molding.

Check the coil packing solution with leading manufacturer for the professional solution just here: Plastic Injection Machine

"Optimizing Injection Mold Testing: Effective Techniques for Plastic Injection Molding Machine and Plastic Injection Machine"