Coil packing line efficiency is a crucial aspect of any manufacturing process that involves the production of ignition coils. Ignition coils play a vital role in the functioning of an engine, as they are responsible for converting the battery's low voltage into the high voltage needed to ignite the fuel-air mixture in the combustion chambers. Therefore, ensuring the efficiency of the coil packing line is essential for optimal engine performance.

In this article, we will explore the importance of coil packing line efficiency and provide insights on how to test a coil pack with the engine running. We will also delve into the various aspects of coil packs, ignition coil replacements, and testing procedures.

Coil packs, also known as coil-on-plug or ignition coil packs, are a compact assembly of ignition coils that are individually mounted on top of each spark plug. They have become a standard feature in modern engines due to their improved performance, reliability, and fuel efficiency compared to traditional distributor-based ignition systems.

However, the efficiency of the coil packing line can significantly impact the overall performance and durability of the coil packs. A well-designed and optimized coil packing line ensures that the coils are properly sealed, insulated, and protected from external factors such as moisture, dust, and temperature fluctuations. This, in turn, enhances the longevity and reliability of the ignition coils.

To assess the efficiency of a coil packing line, various factors need to be considered. These include the speed of the packing process, the accuracy of coil placement, the quality of the sealing materials, and the effectiveness of insulation against electrical interference. A reliable coil packing line should minimize the risk of damage during transportation and storage, ensuring that the coils reach the end-users in pristine condition.

Testing the ignition coil pack with the engine running is an essential procedure to diagnose potential issues and ensure optimal performance. One common test involves using a multimeter to measure the resistance of the coil pack's primary and secondary windings. This test helps identify any faults or discrepancies in the coil pack's electrical conductivity, indicating the need for replacement.

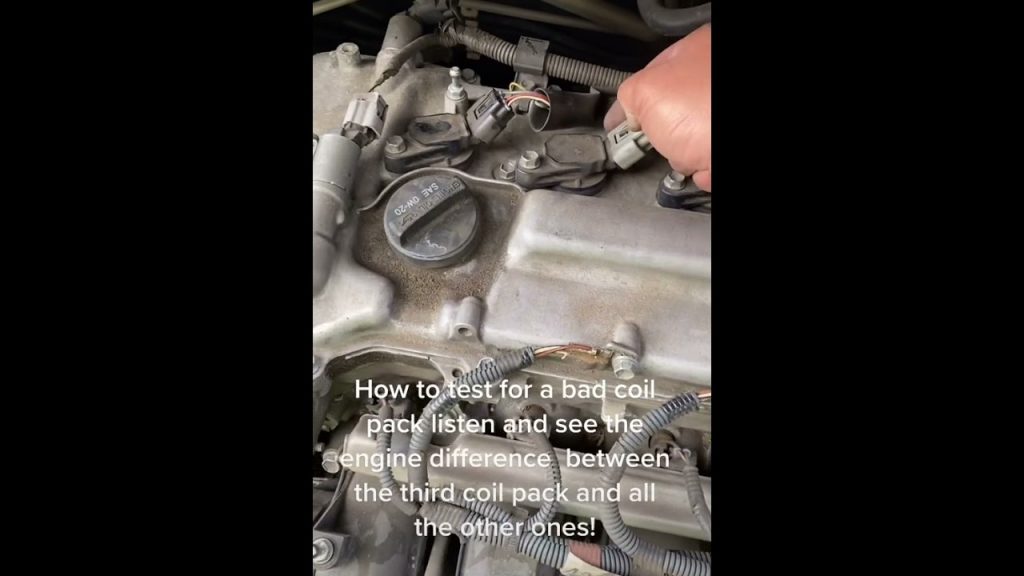

Additionally, conducting a visual inspection of the coil pack can provide valuable insights. Look for signs of physical damage, such as cracks or corrosion, as well as any loose connections or worn-out insulation. Addressing these issues promptly can prevent engine misfires, decreased fuel efficiency, and potential damage to other engine components.

In conclusion, coil packing line efficiency plays a crucial role in ensuring the reliability and performance of ignition coils. A well-optimized coil packing line minimizes the risk of damage during transportation and storage, ultimately enhancing the longevity of the coils. Regular testing of the coil pack with the engine running is essential to diagnose potential issues and maintain optimal engine performance.

Check the coil packing solution with a leading manufacturer for a professional solution. They can provide you with state-of-the-art equipment and expertise to optimize your coil packing line efficiency. Coil packing Line

"Efficient Coil Pack Checking While Engine is Running: A Comprehensive Guide | #shorts"