Turbo impellers play a crucial role in the functioning of turbomachinery by converting exhaust gas pressure into rotary motion. Traditionally, these impellers have been manufactured through casting processes. However, with the advent of industrial robot integration and 3D printing technology, there have been significant advancements in the production of turbo impellers. In this article, we will explore the benefits of industrial robot integration in the manufacturing process of turbo impellers and discuss the use of 3D printed metal impellers in the automotive industry.

Industrial robot integration has revolutionized the manufacturing industry by enhancing productivity, precision, and efficiency. By integrating robots into the production process, manufacturers can streamline operations and improve overall quality. In the case of turbo impellers, industrial robot integration has brought several advantages. Firstly, robots can perform complex tasks with high accuracy, ensuring that impellers are manufactured to precise specifications. This eliminates the risk of human error and guarantees consistent product quality.

Furthermore, industrial robot integration enables increased production capacity. Robots can work tirelessly and at a faster pace than humans, resulting in higher output and reduced lead times. This is particularly beneficial in industries with high demand for turbo impellers, such as the automotive sector. With industrial robot integration, manufacturers can meet the market's needs more efficiently and effectively.

In addition to industrial robot integration, the use of 3D printing technology has also made significant contributions to the production of turbo impellers. 3D printing, also known as additive manufacturing, allows for the creation of complex geometries that are difficult or impossible to achieve through traditional manufacturing methods. This opens up new possibilities for designing turbo impellers with enhanced performance and efficiency.

The automotive industry has been quick to embrace the potential of 3D printed metal turbo impellers. These impellers offer numerous advantages over their traditionally manufactured counterparts. Firstly, 3D printed metal impellers can be customized to meet specific requirements, resulting in improved engine performance. This customization can include optimizing the impeller's shape, size, and blade design, leading to enhanced fuel efficiency and power output.

Additionally, 3D printing allows for the production of lightweight yet durable turbo impellers. By reducing the impeller's weight, manufacturers can minimize rotational inertia, resulting in faster acceleration and improved overall performance. Furthermore, the use of metal materials in 3D printing ensures the impellers' durability and resistance to high temperatures and pressures, making them ideal for automotive applications.

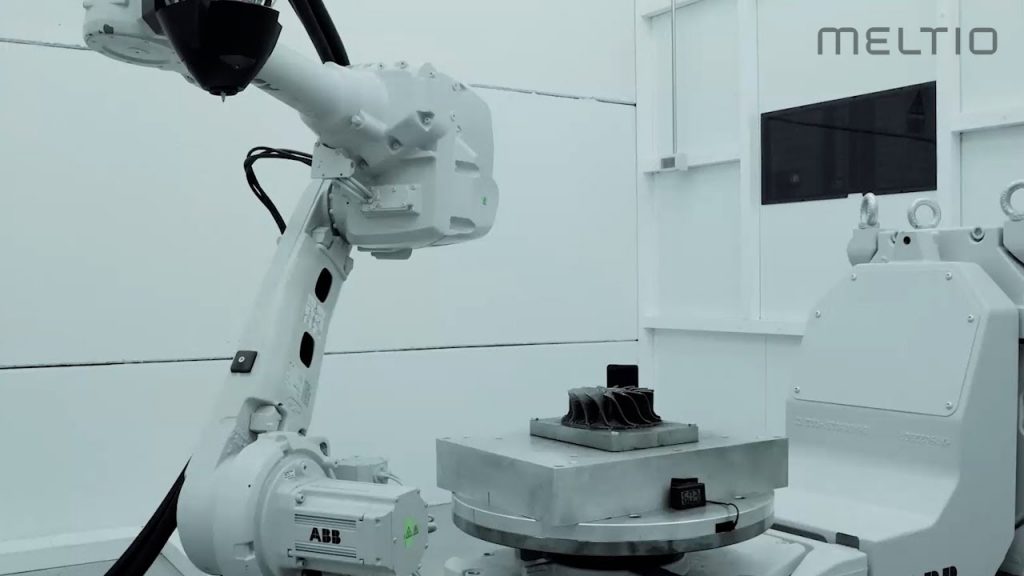

The integration of industrial robots and 3D printing technology has paved the way for significant advancements in the manufacturing of turbo impellers. The combination of precise robotic capabilities and the design freedom offered by 3D printing has revolutionized the production process, resulting in improved product quality, increased production capacity, and enhanced engine performance.

In conclusion, industrial robot integration and 3D printed metal turbo impellers have transformed the automotive industry's approach to manufacturing. With the ability to produce impellers with greater precision, customization, and durability, manufacturers can meet the market's demands more effectively. As technology continues to advance, we can expect further innovations in turbo impeller production, ultimately leading to improved engine efficiency and performance.

Check the coil packing solution with the leading manufacturer for a professional solution. Industrial Robot

"Revolutionizing Automotive Turbo Impellers with 3D Printed Metal - Meltio and Industrial Robot Integration"