Check out our website to explore the leading manufacturer's coil packing solution for all your professional needs.

Title: Enhancing Industrial Safety with ABB Robotic Arm IRB 6700: A Palletizing Robot Revolution

Introduction:

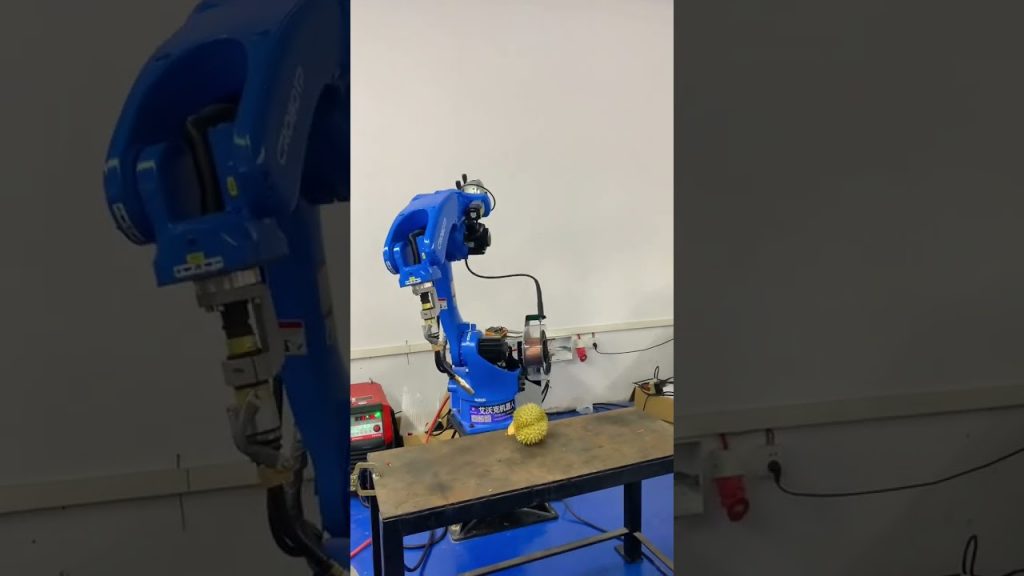

In the world of industrial automation, the ABB Robotic Arm IRB 6700 has emerged as a game-changer. With its remarkable 6-axis payload capacity of 150 kg, this palletizing robot offers unparalleled precision and efficiency. But beyond its impressive capabilities lies a paramount concern for industrial robot safety. In this article, we delve into the intricacies of industrial robot safety and how the ABB Robotic Arm IRB 6700 ensures a secure working environment.

Industrial Robot Safety: A Top Priority:

In an era of increasing automation, safety measures should be at the forefront of every industrial process. Industrial robot safety is no exception. With the ABB Robotic Arm IRB 6700, safety is a top priority. This robotic arm is equipped with cutting-edge safety features, ensuring the well-being of workers and preventing accidents. From risk assessment to enhanced situational awareness, ABB leaves no stone unturned in creating a secure working environment.

Risk Assessment and Safety Standards:

Before integrating the ABB Robotic Arm IRB 6700 into any industrial setting, a comprehensive risk assessment is conducted. This assessment evaluates potential hazards and implements safety measures accordingly. The robot is designed to comply with stringent safety standards, ensuring its safe operation in diverse applications such as MIG welding, TIG, and palletizing. ABB's commitment to safety is exemplified through its adherence to ISO 13849-1 and ISO 10218-1 safety standards.

Enhanced Situational Awareness:

ABB understands the importance of situational awareness in preventing accidents. The ABB Robotic Arm IRB 6700 is equipped with advanced sensors and intelligent control systems to detect and respond to any potential risks. These sensors enable the robot to adapt its trajectory and speed, ensuring safe collaboration with human workers. The robot's ability to detect changes in its environment and adjust its movements accordingly is a testament to ABB's focus on industrial robot safety.

Collaborative Robotics:

Collaborative robotics is transforming the industrial landscape, and the ABB Robotic Arm IRB 6700 is at the forefront of this revolution. This robot is designed to work alongside human operators, enhancing productivity and efficiency. With features like safety-rated monitored stop and speed and separation monitoring, the ABB Robotic Arm IRB 6700 guarantees safe collaboration, minimizing the risk of accidents while optimizing operational efficiency.

Conclusion:

As industrial automation continues to evolve, ensuring the safety of workers remains paramount. The ABB Robotic Arm IRB 6700 sets new benchmarks in industrial robot safety, combining state-of-the-art technology with rigorous safety standards. Its ability to perform tasks like MIG welding, TIG, and palletizing with utmost precision and efficiency is complemented by its unwavering commitment to the well-being of workers. Embrace the future of industrial automation with the ABB Robotic Arm IRB 6700, where productivity and safety go hand in hand.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert Link] Industrial Robot

"Enhancing Palletizing Efficiency with a High Payload Industrial Robot Arm: ABB IRB 6700 6-Axis Robotic Arm & Ensuring Safety"