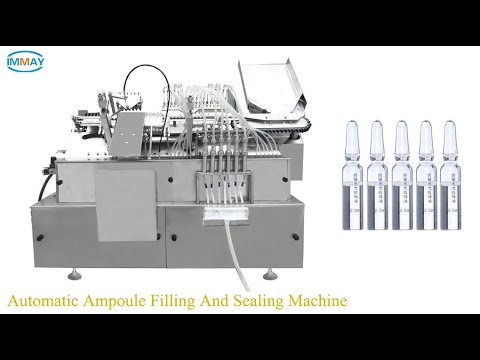

Check out our video on Ampoule Filling and Sealing Machine, a versatile solution for filling and sealing ampoules in the pharmaceutical, cosmetic, and chemical industries. This advanced machine, manufactured by Immay Machine Company, offers cutting-edge technology and exceptional performance. In this article, we will discuss the features and benefits of the Ampoule Filling and Sealing Machine, as well as its applications and relevance in the industry.

[Introduction]

Are you looking for an efficient and reliable solution for filling and sealing ampoules? Look no further than the Ampoule Filling and Sealing Machine. With its state-of-the-art technology and precision engineering, this machine is designed to meet the needs of various industries, including pharmaceutical, cosmetic, and chemical.

[Features and Benefits]

The Ampoule Filling and Sealing Machine offers a range of features that make it a superior choice for ampoule packaging. These include:

1. High-speed filling: The machine is equipped with advanced filling mechanisms that allow for quick and accurate filling of ampoules. This ensures high productivity and efficiency in the packaging process.

2. Precise sealing: With its advanced sealing technology, the machine ensures a tight and secure seal on every ampoule. This helps to maintain product integrity and prevent leaks or contamination.

3. Versatile applications: The Ampoule Filling and Sealing Machine is suitable for a wide range of ampoule sizes and shapes, making it highly versatile for different product requirements. Whether you need to fill and seal small or large ampoules, this machine can handle it all.

4. Easy operation: The machine is designed for user-friendly operation, with intuitive controls and a user-friendly interface. This allows for easy setup, adjustment, and monitoring of the filling and sealing process.

5. High-quality construction: Immay Machine Company is known for its commitment to quality and durability. The Ampoule Filling and Sealing Machine is built to withstand the demands of continuous production, ensuring long-term reliability and performance.

[Applications]

The Ampoule Filling and Sealing Machine finds extensive applications in various industries:

1. Pharmaceutical: This machine is widely used in the pharmaceutical industry for filling and sealing ampoules containing medicines, vaccines, and other healthcare products. Its precise and hygienic operation ensures the integrity and safety of the pharmaceutical products.

2. Cosmetic: Many cosmetic products, such as serums, oils, and ampoule treatments, are packaged in ampoules. The Ampoule Filling and Sealing Machine provides a reliable solution for efficient and aesthetically pleasing packaging of cosmetic ampoules.

3. Chemical: In the chemical industry, ampoules are commonly used for packaging sensitive or hazardous substances. The Ampoule Filling and Sealing Machine ensures proper containment and sealing of these substances, minimizing the risk of leaks or spills.

[Conclusion]

In conclusion, the Ampoule Filling and Sealing Machine by Immay Machine Company is a top-of-the-line solution for filling and sealing ampoules. Its advanced features, versatility, and user-friendly operation make it an ideal choice for industries such as pharmaceutical, cosmetic, and chemical. With this machine, you can achieve efficient and reliable packaging of your products, ensuring their integrity and safety.

Check out the Ampoule Filling and Sealing Machine video to see it in action and learn more about its capabilities. Don't miss the opportunity to enhance your ampoule packaging process with this innovative machine!

[Check the coil packing solution with leading manufacturer for the professional solution just here: (insert link to the manufacturer's website)] Filling Packing Machine

"Efficient Ampoule Filling and Sealing Machine: Streamline Your Packaging Process"