Check out the leading manufacturer for professional coil packing solutions here: [Link to Manufacturer's Website].

Title: Enhancing Efficiency with Our Stainless Steel FPS Series Filling and Sealing Machine

Introduction:

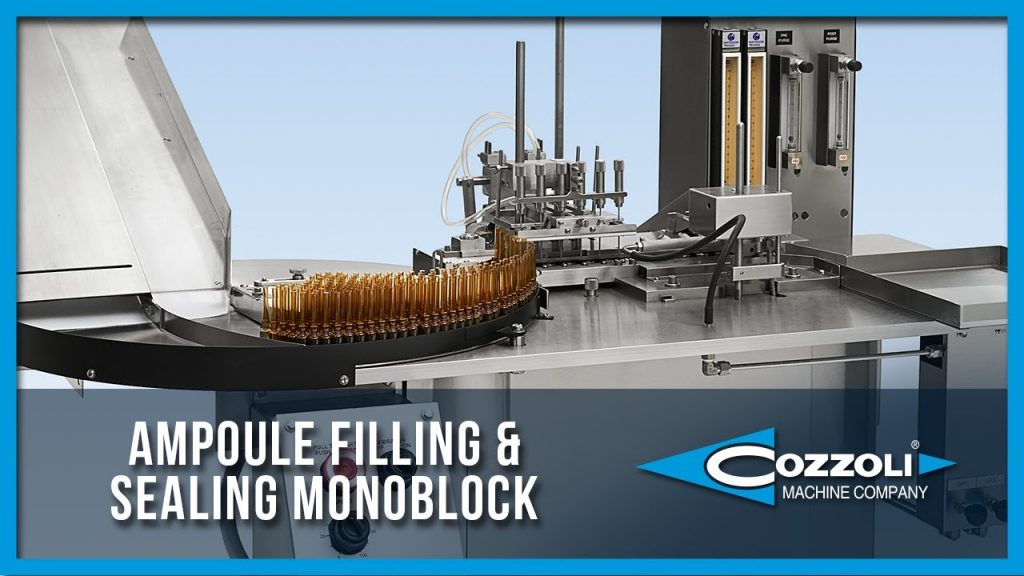

In today's fast-paced manufacturing industry, efficiency is key. To meet the demands of high-speed production, businesses need reliable and technologically advanced equipment. This is where our stainless steel FPS Series comes into play. Designed to fill and seal ampoules at impressive speeds of 15-120 ampoules per minute, our FPS Series Filling and Sealing Machine offers exceptional performance and accuracy. In this article, we will explore the features and benefits of this cutting-edge machine, shedding light on how it can revolutionize your production line.

Keyword: Filling and Sealing Machine

Section 1: The Versatility of the FPS Series

Our stainless steel FPS Series is a versatile filling and sealing machine that caters to a wide range of ampoule packaging needs. Whether you are in the pharmaceutical, cosmetic, or food and beverage industry, this machine is designed to handle various liquid products with ease. From small ampoules to larger containers, the FPS Series can accommodate different sizes, making it a flexible solution for your packaging requirements.

Section 2: Unparalleled Speed and Accuracy

One of the key advantages of our FPS Series is its impressive speed capabilities. With a range of 15-120 ampoules per minute, this machine ensures efficient production without compromising on accuracy. Each ampoule is filled precisely to the desired level, providing consistent and reliable results. This not only saves time but also minimizes product wastage, contributing to overall cost-effectiveness.

Section 3: Superior Quality and Durability

Manufactured with high-grade stainless steel, the FPS Series guarantees exceptional quality and longevity. The use of this material ensures resistance to corrosion, rust, and other environmental factors, prolonging the lifespan of the machine. Additionally, the stainless steel construction facilitates easy cleaning and maintenance, ensuring a hygienic production environment.

Section 4: User-Friendly Interface and Customization Options

Our FPS Series is designed with user convenience in mind. The machine features a user-friendly interface, allowing operators to easily control and monitor the filling and sealing process. Additionally, customization options are available to cater to specific production needs. From adjustable filling volumes to customizable sealing parameters, the FPS Series can be tailored to meet your unique requirements, further enhancing efficiency and productivity.

Section 5: Safety and Compliance

We understand the importance of safety and compliance in the manufacturing industry. The FPS Series is equipped with advanced safety features, ensuring operator protection and adherence to industry regulations. From safety interlocks to emergency stop buttons, this machine prioritizes the well-being of your workforce while maintaining compliance with industry standards.

Section 6: Innovative Technology for the Future

As technology advances, so does the need for innovative solutions. Our FPS Series embodies state-of-the-art technology, keeping your production line ahead of the curve. With continuous research and development, we strive to provide cutting-edge features and functionalities, enabling you to stay competitive in the ever-evolving market.

Conclusion:

In conclusion, our stainless steel FPS Series Filling and Sealing Machine offers a game-changing solution for businesses in need of high-speed and accurate ampoule packaging. With its versatility, speed, durability, user-friendly interface, and commitment to safety, the FPS Series is a must-have addition to your production line. Embrace the future of packaging technology by investing in our FPS Series and experience enhanced efficiency like never before.

Check out the leading manufacturer for professional coil packing solutions here: [Link to Manufacturer's Website]. Filling Packing Machine

"Efficient Ampoule Filling & Sealing Machine: Streamlining the Filling and Sealing Process"