Title: Packaging Line Automation and Flow Wrapper for Efficient and Precise Product Packaging

Description:

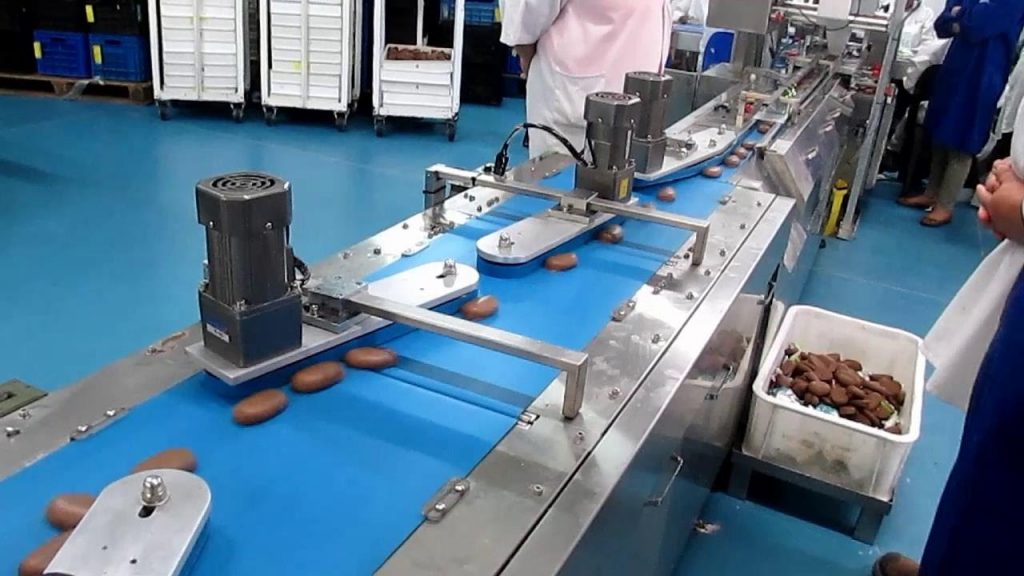

In this comprehensive video, we explore the world of packaging line automation and introduce the Aligner Feeder Flowpack system, specifically designed for the automated packaging of various products such as bars and chocolates. Our focus is on the FWC350 high-speed flow wrapper, equipped with an in-line feeder, ensuring seamless automatic feeding and wrapping of small to medium-sized items.

Introduction:

Welcome to our informative video on packaging line automation and the innovative Aligner Feeder Flowpack system. This video aims to provide you with a detailed overview of how this technology revolutionizes the packaging process for bars and chocolates, enhancing efficiency and precision.

Video Content:

1. Understanding Packaging Line Automation:

- Definition and importance of automated packaging systems.

- Benefits of implementing automation in the packaging industry.

- Increased productivity, reduced errors, and improved cost-effectiveness.

2. Introduction to Aligner Feeder Flowpack:

- Overview of the Aligner Feeder Flowpack system.

- How it streamlines the packaging process, ensuring accurate alignment and feeding.

- Specialized design features catering to small and medium-sized products.

3. Exploring the FWC350 High-Speed Flow Wrapper:

- Detailed examination of the FWC350 flow wrapper and its key functionalities.

- High-speed capabilities for efficient packaging operations.

- In-line feeder integration for seamless product feeding and wrapping.

4. Operation Steps:

- Step-by-step guide on how to operate the Aligner Feeder Flowpack system.

- Demonstrating the loading of products, adjusting settings, and initiating the packaging process.

- Highlighting the system's reliability, precision, and ease of use.

Call to Action:

If you found this video informative and valuable, please consider liking, subscribing, and sharing it with others interested in packaging line automation and flow wrapping solutions. Stay updated with our channel for more insightful content on the latest advancements in the packaging industry.

Additional Tags and Keywords:

packaging line automation, automated packaging, Aligner Feeder Flowpack, high-speed flow wrapper, automated chocolate packaging line, product packaging, small and medium-sized products, efficiency, precision, streamlining operations, packaging process, automated feeding and wrapping.

Hashtags:

#PackagingAutomation #FlowWrapper #AlignerFeederFlowpack #AutomatedPackaging #EfficientPackaging #ProductPackaging #FWC350 #HighSpeedFlowWrapper #PackagingIndustry

Title: Automated Packaging Solutions for Aligner Feeder Flowpack and Chocolate Bars

Introduction:

In recent years, automation has revolutionized the packaging industry, offering increased efficiency, accuracy, and speed. This tilter for Aligner Feeder Flowpack and automated chocolate packaging line is designed to streamline the packaging process, ensuring optimal productivity and product quality. Let's explore the features and benefits of this cutting-edge packaging solution.

1. Enhanced Efficiency:

By automating the packaging process, this tilter for Aligner Feeder Flowpack guarantees a significant increase in efficiency. It eliminates the need for manual handling, reducing the risk of errors and ensuring a seamless workflow. With a high-speed operation, it maximizes productivity, allowing manufacturers to meet high-demand requirements.

2. Precise Aligner Feeder Flowpack:

This tilter ensures precise alignment of the bars before they enter the flowpack. It carefully positions each bar, minimizing the chances of misplacement or misalignment during the packaging process. This level of precision enhances the overall appearance of the packaged products, presenting a professional and appealing final result.

3. Customizable Packaging Solutions:

The automated chocolate packaging line integrated with this tilter offers a wide range of customizable packaging options. Manufacturers can easily adapt to various bar sizes, shapes, and branding requirements. This flexibility allows businesses to cater to different customer preferences, resulting in increased customer satisfaction and brand loyalty.

4. Quality Assurance:

Maintaining the quality of chocolate bars is crucial for businesses in the confectionery industry. This automated packaging solution guarantees consistent quality control throughout the packaging process. By using advanced sensors and monitoring systems, it detects any defects or anomalies, ensuring only flawless bars are packaged. This level of quality assurance enhances product integrity and customer satisfaction.

5. Improved Safety Measures:

With the automated tilter, this packaging solution ensures a safer working environment. It minimizes the risk of injuries associated with manual handling, reducing the physical strain on workers. By eliminating repetitive tasks, it allows employees to focus on more complex and value-added activities, fostering a safer and more engaging workplace.

6. Integration with Existing Systems:

This tilter for Aligner Feeder Flowpack and chocolate packaging line can seamlessly integrate with existing production systems. It offers compatibility with various upstream and downstream equipment, enabling easy integration into the existing packaging line. This integration minimizes disruptions during implementation and reduces the need for extensive modifications or equipment replacements.

Conclusion:

The tilter for Aligner Feeder Flowpack and automated chocolate packaging line is a game-changer in the confectionery industry. Its automation capabilities, precise alignment, customization options, quality assurance, and safety measures make it an invaluable asset for manufacturers. By investing in this automated packaging solution, businesses can optimize their packaging processes, increase productivity, and deliver exceptional quality products to meet customer demands. Automatic Packing Line

#Aligner #Feeder #Flowpackautomated #packaging #bars #automated #chocolate #packaging #line