Title: Advanced Industrial Food Packing Machine | Raisin Packing Multihead Weigher | Sensograph

Description:

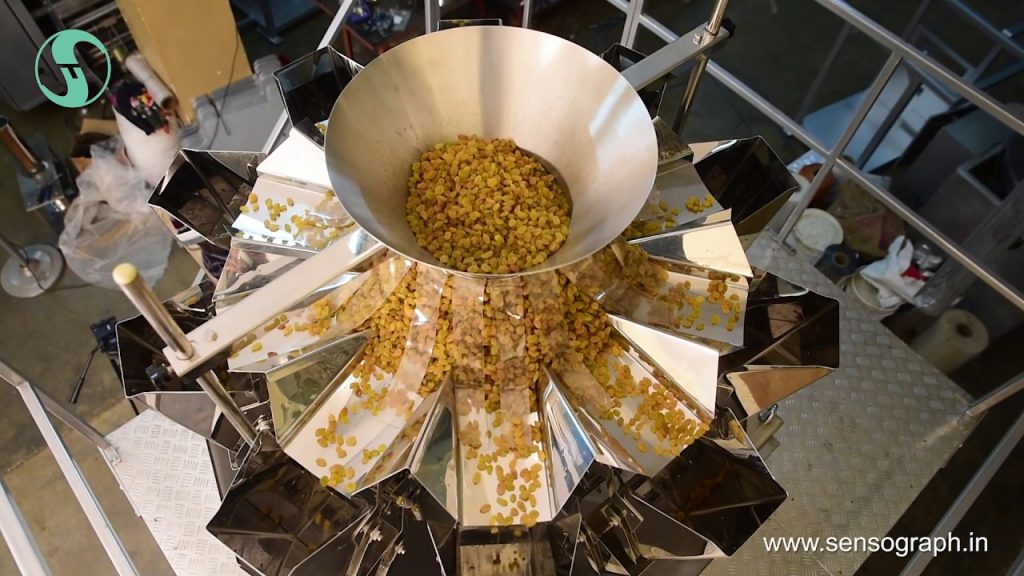

Welcome to Sensograph's cutting-edge Industrial Food Packing Machine! Our state-of-the-art Raisin Packing Multihead Weigher is designed to streamline your food packaging process, ensuring efficiency, accuracy, and superior quality.

In this informative video, we delve into the various features and benefits of our advanced food packing machine. From its precision weighing capabilities to its seamless integration with your production line, our machine guarantees optimal packaging solutions for a wide range of food products, including raisins.

Key Points:

1. Unparalleled Precision: Discover how our multihead weigher ensures accurate weighing of your food items, eliminating any variations in portion sizes.

2. High-Speed Packaging: Experience the efficiency and speed of our machine as it effortlessly packs a large volume of products in a short amount of time.

3. Versatile Packaging Options: Learn about the multiple packaging formats our machine supports, allowing you to cater to diverse customer preferences and market demands.

4. User-Friendly Interface: Explore the intuitive control panel and user-friendly interface, enabling your operators to easily navigate and manage the machine's functions.

5. Advanced Technology: Gain insights into the cutting-edge technology utilized in our food packing machine, ensuring reliability, durability, and minimal maintenance requirements.

6. Customizable Solutions: Discover how our machine can be tailored to meet your specific packaging requirements, ensuring a perfect fit for your business needs.

7. Exceptional Quality Assurance: Learn about the built-in quality control mechanisms that guarantee the integrity and freshness of your packaged food products.

At Sensograph, we are committed to providing top-notch packaging solutions to enhance your productivity and profitability. For more information and to explore the endless possibilities our Industrial Food Packing Machine offers, feel free to contact us at [INSERT CONTACT DETAILS].

Don't forget to like, subscribe, and share this video to stay updated with the latest advancements in the food packaging industry!

Additional Tags: industrial food packaging, automated packing machine, food packaging solutions, multihead weigher, advanced packaging technology, efficient food packaging, precision weighing, packaging automation, quality control, food industry.

Hashtags: #FoodPackingMachine #IndustrialPackaging #RaisinPacking #Sensograph

Title: Automated Food Packing Machine for Raisins: A Tilter Solution

Introduction:

In order to optimize the packaging process of raisins, a tilter solution for a multihead weigher machine, specifically designed for raisin packing, is proposed. The tilter will streamline the packaging process, ensuring efficient and accurate weighing and packaging of raisins. This article outlines the key features and benefits of the tilter for the raisin packing multihead weigher machine, manufactured by Sensograph.

1. Enhanced Efficiency:

The tilter incorporated into the raisin packing multihead weigher machine significantly increases the overall efficiency of the packaging process. It automates the tilting of the weighing buckets, allowing for a seamless transfer of raisins to the packaging stage. This eliminates the need for manual intervention, reducing the downtime and increasing productivity.

2. Improved Accuracy:

By automating the tilting process, the tilter ensures precise weighing of raisins. The system allows for accurate measurement and distribution of the desired weight into each packaging unit. This eliminates inconsistencies and minimizes product giveaway, resulting in cost savings and improved customer satisfaction.

3. Gentle Handling:

The tilter is designed to handle raisins delicately, preventing damage or breakage during the packaging process. The controlled tilting motion ensures that the raisins are transferred smoothly, without any excessive force or impact. This gentle handling maintains the quality and integrity of the raisins, preserving their appearance and taste.

4. Versatility and Customization:

The Sensograph raisin packing multihead weigher machine with a tilter offers versatility and customization options to meet specific packaging requirements. The tilter can be adjusted to accommodate different packaging sizes, weights, and formats. This adaptability allows raisin manufacturers to cater to various market demands efficiently.

5. Easy Integration:

The tilter seamlessly integrates with the existing Sensograph raisin packing multihead weigher machine, making it easy to incorporate into the packaging line. The user-friendly interface and intuitive controls ensure a smooth transition without extensive training or operational challenges.

6. Hygienic Design:

The tilter is constructed using food-grade materials and incorporates a hygienic design. It is easy to clean and maintain, ensuring compliance with food safety standards. The absence of crevices or hard-to-reach areas prevents the accumulation of debris and contaminants, guaranteeing the highest level of food safety.

Conclusion:

The tilter for the Sensograph raisin packing multihead weigher machine offers numerous advantages for the packaging of raisins. With enhanced efficiency, improved accuracy, gentle handling, versatility, easy integration, and hygienic design, this tilter solution optimizes the raisin packaging process. By investing in this technology, raisin manufacturers can streamline operations, reduce costs, and deliver high-quality products to meet customer demands.Food Packing Machine

#food #packing #machine #Raisin #Packing #Multihead #Weigher #Machine #Sensograph