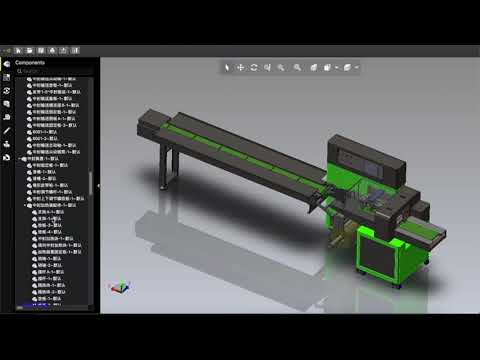

Title: High-Speed Automatic Packing Machine Design | Packing Speed: 50-60 pcs/minute | Weight: 900 KG | Packing Size: Adjustable | Machine Size: 1450*4020*770 | Design: Solidwork

Description:

Introduction:

Welcome to our video showcasing the state-of-the-art High-Speed Automatic Packing Machine. In this video, we will provide a comprehensive overview of its design, features, and capabilities. Whether you are a business owner in need of an efficient packing solution or simply interested in the latest advancements in manufacturing technology, this video is for you.

Video Content:

Our High-Speed Automatic Packing Machine is designed to revolutionize the packing process, increasing productivity and efficiency. With a packing speed of 50-60 pieces per minute, this machine is capable of handling high-volume production requirements. Its robust design, weighing 900 KG, ensures stability and durability even in demanding industrial environments.

The packing size of this machine is adjustable, allowing flexibility to accommodate various product dimensions. Its compact machine size, measuring 1450*4020*770, optimizes space utilization in your production area. Designed using Solidwork, a leading 3D CAD software, this machine is built with precision and attention to detail.

Operation Steps:

1. Step 1: Prepare the machine for operation by ensuring all components are securely in place.

2. Step 2: Adjust the packing size according to your product requirements.

3. Step 3: Place the products to be packed in the designated area.

4. Step 4: Start the machine and witness its high-speed packing capabilities.

5. Step 5: Monitor the process and make any necessary adjustments for optimal performance.

Call to Action:

If you found this video informative and helpful, please give it a thumbs up and consider subscribing to our channel for more exciting content. Don't forget to share this video with others who might benefit from this cutting-edge packing machine.

Additional Tags and Keywords:

Automatic Packing Machine, Packing Machine Design, Packing Speed, High-Speed Packing Machine, Adjustable Packing Size, Solidwork Design, Industrial Packaging Solution, High-Volume Packing, Manufacturing Efficiency, Productivity Enhancement, Packing Process Optimization, Precision Packing Machine, Advanced Packing Technology.

Hashtags:

#AutomaticPackingMachine #PackingMachineDesign #HighSpeedPacking #SolidworkDesign #IndustrialPackaging #ManufacturingTechnology #EfficientPackingSolution #ProductivityEnhancement

A tilter is an essential component of an automatic packing machine design. It is responsible for tilting the products or packages at a certain angle to facilitate the packing process. Here is a sample tilter design for an automatic packing machine:

1. Structure: The tilter should have a sturdy and durable frame made of high-quality materials such as stainless steel or aluminum. It should be designed to withstand heavy loads and continuous operation.

2. Tilting Mechanism: The tilter should be equipped with a reliable and efficient tilting mechanism. This can be achieved by using hydraulic or pneumatic cylinders to control the tilting motion. These cylinders should be able to exert enough force to tilt the products without causing any damage.

3. Tilting Angle Control: The tilter should have a control system that allows the operator to set the desired tilting angle. This can be achieved by using a programmable logic controller (PLC) or a human-machine interface (HMI) panel. The control system should be user-friendly and provide precise control over the tilting angle.

4. Safety Features: Safety should be a top priority when designing a tilter for an automatic packing machine. It should be equipped with safety sensors that detect any obstructions or malfunctions during the tilting process. Emergency stop buttons should also be incorporated to immediately halt the operation in case of an emergency.

5. Adjustable Height: The tilter should have an adjustable height feature to accommodate different product sizes and packaging requirements. This can be achieved by incorporating telescopic legs or adjustable platforms.

6. Conveyor Integration: The tilter should be seamlessly integrated with the conveyor system of the automatic packing machine. It should be designed to receive products from the conveyor and deliver them to the packing station after tilting.

7. Easy Maintenance: The tilter should be designed for easy maintenance and servicing. Accessible maintenance points, clear instructions for lubrication and upkeep, and easily replaceable parts should be incorporated to minimize downtime and ensure smooth operation.

8. Customizability: The tilter should be customizable to meet specific packing requirements. This can include options for tilting speed control, multiple tilting angles, or special attachments for handling unique products.

By integrating a well-designed tilter into an automatic packing machine, the packing process can be significantly improved in terms of efficiency, accuracy, and safety. Automatic Packing Line

#Automatic #Packing #Machine #Design