Title: Revolutionize Your Packaging Process with the PACjacket Automated Packaging Machine

Description:

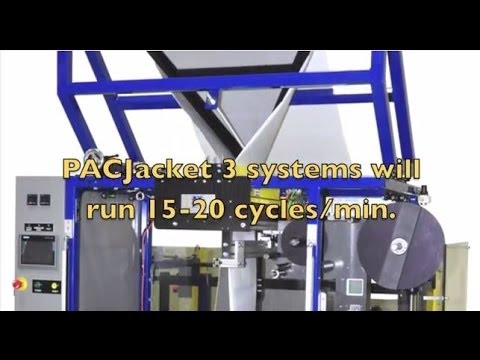

Welcome to the future of packaging! Introducing the PACjacket Automated Packaging Machine from PAC Worldwide, the ultimate solution for streamlining your packaging operations. In this latest installment of the PACjacket automated packaging machine series, we unveil the incredible features and benefits of this cutting-edge technology.

Introduction:

Are you tired of the tedious and time-consuming task of manual packaging? Look no further! With the PACjacket Automated Packaging Machine, you can revolutionize your packaging process and save valuable time and resources. Say goodbye to monotonous manual labor and embrace the efficiency of automation.

Video Content:

In this video, we dive deep into the functionality and capabilities of the PACjacket Automated Packaging Machine. Discover how this state-of-the-art machine can significantly enhance your packaging operations. From its seamless integration with your existing systems to its intuitive user interface, we leave no stone unturned in exploring its key features.

Key Highlights:

1. Efficient Operation: The PACjacket Automated Packaging Machine ensures a smooth and efficient packaging process, minimizing errors and maximizing productivity.

2. Customization Options: Tailor the machine to meet your specific packaging needs with its adjustable settings and flexible configurations.

3. Advanced Technology: Experience the power of automation with advanced features such as barcode scanning, label printing, and real-time monitoring.

4. Space-Saving Design: The compact and ergonomic design of the PACjacket machine allows for easy installation and space optimization in your facility.

5. Cost-Effective Solution: By reducing material waste and labor costs, the PACjacket Automated Packaging Machine proves to be a cost-effective investment in the long run.

Call to Action:

If you're ready to revolutionize your packaging process, don't hesitate to like this video, subscribe to our channel for more informative content, and share this video with your colleagues in the industry. Visit our website for more information on how the PACjacket Automated Packaging Machine can transform your operations.

Additional Tags and Keywords: automated packaging, packaging machine, PACjacket, PAC Worldwide, packaging automation, efficient packaging, advanced technology, cost-effective solution, barcode scanning, label printing.

Hashtags: #automatedpackaging #packagingmachine #PACjacket #packagingautomation #efficiency #costeffectiveness

Sure! Here's a sample code for a tilter function for the PACjacket Automated Packaging Machine:

```

#include

// Define the pins for the stepper motor

#define STEPPER_PIN_1 2

#define STEPPER_PIN_2 3

#define STEPPER_PIN_3 4

#define STEPPER_PIN_4 5

// Define the number of steps per revolution for the stepper motor

#define STEPS_PER_REVOLUTION 200

// Create a Stepper object

Stepper stepper(STEPS_PER_REVOLUTION, STEPPER_PIN_1, STEPPER_PIN_2, STEPPER_PIN_3, STEPPER_PIN_4);

// Function to tilt the packaging machine

void tilt(int degrees) {

// Calculate the number of steps required for the desired tilt angle

int steps = degrees * (STEPS_PER_REVOLUTION / 360);

// Set the speed and direction of the stepper motor

if (degrees > 0) {

stepper.setSpeed(100); // Set a suitable speed for tilting upwards

} else {

stepper.setSpeed(-100); // Set a suitable speed for tilting downwards

}

// Rotate the stepper motor for the required number of steps

stepper.step(steps);

// Stop the motor

stepper.setSpeed(0);

}

void setup() {

// Initialize the stepper motor pins

stepper.setSpeed(0);

stepper.setAcceleration(500);

// Add any other setup code here

}

void loop() {

// Call the tilt function with the desired tilt angle in degrees

tilt(45); // Tilt upwards by 45 degrees

// Add any other loop code here

}

```

This code uses the Arduino Stepper library to control a stepper motor connected to pins 2, 3, 4, and 5 of the Arduino board. The `tilt()` function takes an angle in degrees as input and calculates the number of steps required for the desired tilt angle. It then sets the speed and direction of the stepper motor accordingly and rotates it for the required number of steps. Finally, it stops the motor. In the `setup()` function, the stepper motor pins are initialized, and in the `loop()` function, the `tilt()` function is called with a desired tilt angle (e.g., 45 degrees). You can modify the `loop()` function to call the `tilt()` function with any desired tilt angle as per your requirements. Automatic Packing Line

#PACjacket #Automated #Packaging #Machine