Title: Ultimate Guide to Automatic Packing Line Manufacturers - JXC Automatic Battery PACK Assembly Line for E-Vehicles, E-Bikes, E-Tools, Energy Storage

Description:

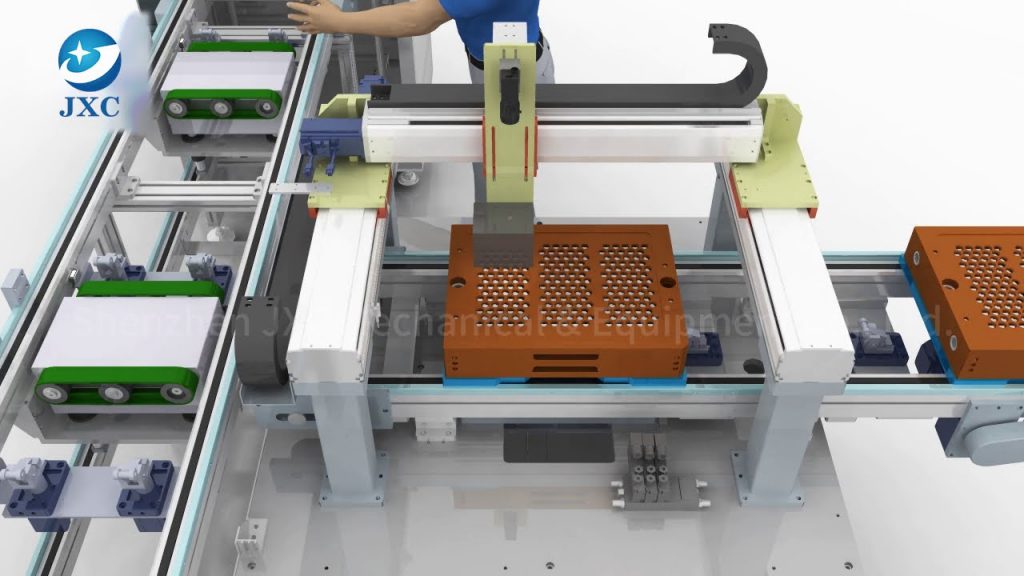

Welcome to the ultimate guide on automatic packing line manufacturing, specifically focusing on the cutting-edge JXC Automatic Battery PACK Assembly Line for E-Vehicles, E-Bikes, E-Tools, and Energy Storage. In this comprehensive video, we delve into the intricate details of our state-of-the-art machinery, designed to revolutionize the battery production industry.

Introduction:

Join us as we take you on an exciting journey through the world of automatic packing line manufacturing. In this video, we are thrilled to introduce the JXC Automatic Battery PACK Assembly Line, a game-changer in the E-Vehicles, E-Bikes, E-Tools, and Energy Storage sectors. Get ready to explore the extraordinary features and benefits of our advanced machinery.

Video Content:

1. Overview of JXC Automatic Battery PACK Assembly Line: Discover the cutting-edge technology behind our assembly line, engineered to streamline and optimize the battery production process.

2. Key Features and Benefits: Uncover the remarkable features that set our machinery apart, including high efficiency, precision, scalability, and adaptability to various battery types.

3. Operation Steps: Gain insight into the step-by-step process of operating the JXC Automatic Battery PACK Assembly Line, ensuring seamless production and maximum output.

4. Applications: Learn about the wide range of applications for our assembly line, catering to the growing demand in the E-Vehicles, E-Bikes, E-Tools, and Energy Storage industries.

5. Industry-Leading Quality: Explore how our state-of-the-art machinery adheres to the highest industry standards, ensuring superior quality and reliability.

Call to Action:

If you found this video informative and insightful, don't forget to hit the like button, subscribe to our channel, and share this video with your colleagues and industry peers. Stay updated with the latest advancements in battery production technology by joining our community today!

Additional Tags and Keywords:

Automatic packing line, battery pack assembly line, E-Vehicles, E-Bikes, E-Tools, energy storage, machinery, manufacturing, production, technology, efficiency, precision, scalability, reliability, industry standards.

Hashtags:

#AutomaticPackingLine #BatteryPackAssemblyLine #EVehicles #EBikes #ETools #EnergyStorage #Manufacturing #Technology #Efficiency #Precision #Reliability

Title: JXC Automatic Battery Pack Assembly Line: Transforming E-Vehicles, E-Bikes, E-Tools, and Energy Storage

Introduction:

The JXC Automatic Battery Pack Assembly Line offers a revolutionary solution for the assembly of battery packs used in various applications, including electric vehicles (E-Vehicles), E-Bikes, E-Tools, and energy storage units. This cutting-edge technology streamlines the manufacturing process, ensuring efficiency, precision, and high-quality output. Let's delve into the features and benefits of the JXC Automatic Battery Pack Assembly Line.

1. Automated Assembly Process:

The JXC Assembly Line eliminates the need for manual labor, reducing human error and ensuring consistent production quality. With its advanced robotics and intelligent control systems, the assembly process is automated, resulting in faster production rates and increased efficiency.

2. Versatility and Adaptability:

Designed to cater to a wide range of applications, the JXC Assembly Line can handle various battery pack sizes, shapes, and chemistries, accommodating the diverse needs of E-Vehicles, E-Bikes, E-Tools, and energy storage units. This versatility allows manufacturers to streamline their production lines, saving time and resources.

3. Quality Control:

The JXC Assembly Line integrates advanced quality control mechanisms, including automated testing and inspection systems. These measures ensure that each battery pack meets the highest industry standards, guaranteeing reliability, safety, and performance.

4. Traceability and Data Management:

With built-in traceability and data management features, the JXC Assembly Line enables manufacturers to monitor and track the production process. This comprehensive data collection facilitates analysis, troubleshooting, and optimization, ensuring continuous improvement in manufacturing operations.

5. Modular Design and Scalability:

The JXC Assembly Line is built with a modular design, allowing for easy customization and scalability. Manufacturers can add or remove modules based on their specific requirements, adapting to changing market demands and expanding production capabilities effortlessly.

6. Enhanced Worker Safety:

By automating the assembly process, the JXC Assembly Line reduces the need for manual labor, minimizing potential risks for workers. This emphasis on worker safety not only ensures a secure working environment but also boosts productivity and employee satisfaction.

7. Cost-effectiveness and ROI:

Investing in the JXC Assembly Line yields substantial cost savings in the long run. By streamlining the assembly process, reducing labor costs, and minimizing errors, manufacturers can achieve increased production output and improved overall efficiency. This, in turn, maximizes return on investment (ROI) and enhances competitiveness in the market.

Conclusion:

The JXC Automatic Battery Pack Assembly Line revolutionizes the manufacturing process for E-Vehicles, E-Bikes, E-Tools, and energy storage units. With its automated assembly process, versatility, quality control measures, traceability features, and scalability, the JXC Assembly Line ensures manufacturers can meet the growing demand for battery packs while maintaining high standards of efficiency and precision. Embrace this cutting-edge technology to transform your battery pack assembly operations and stay ahead in the evolving market of electric mobility and energy storage. Automatic Packing Line

#JXC #Automatic #Battery #PACK #Assembly #Line #EVehicles #EBikesEToolsEnergy #storage