Check out the leading manufacturer for all your coil packing needs here:

Are you tired of spending valuable time and effort manually wrapping your cabinet doors for shipping? Look no further than the Automatic Orbital Stretch Wrapper! This innovative machine from Plasticband, the industry leader in packaging solutions, is revolutionizing the way cabinet doors are wrapped and protected during transit.

In this article, we will dive deep into the features and benefits of the Automatic Orbital Stretch Wrapper, providing you with a comprehensive understanding of how it can streamline your packaging process and improve efficiency. Whether you are a sales engineer in the manufacturing industry or simply interested in the latest packaging technology, this article is for you.

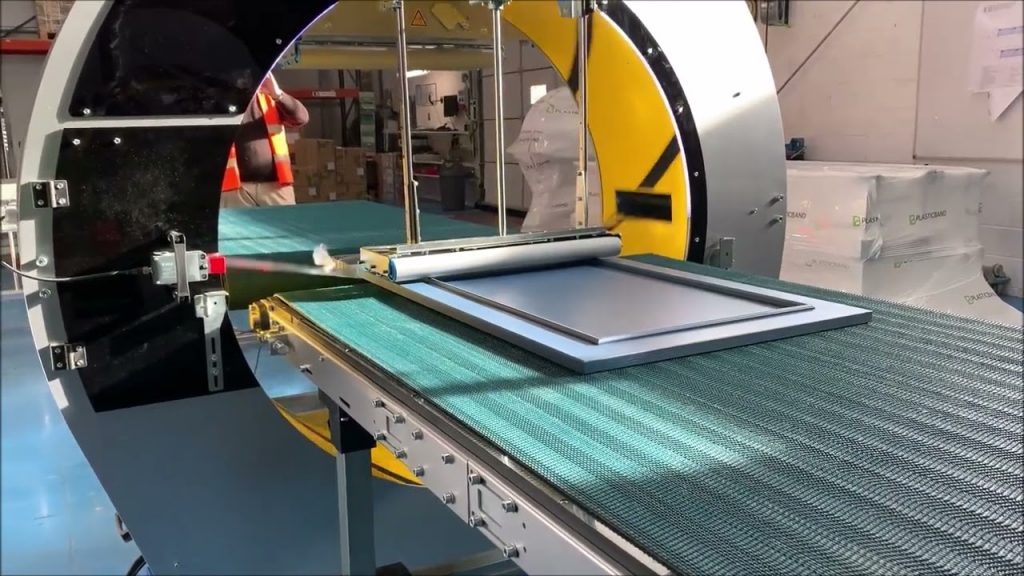

The Automatic Orbital Stretch Wrapper, specifically the Plasticband ATIS-125 model, is designed to automate the process of wrapping cabinet doors securely and efficiently. With its state-of-the-art technology, this machine can significantly reduce labor costs and eliminate the risk of human error. Plus, it ensures consistent wrapping quality, providing added protection to your valuable products.

One of the key features of the Automatic Orbital Stretch Wrapper is its automatic feeding system. This system allows for seamless integration with your production line, ensuring a continuous flow of cabinet doors to be wrapped. With its high-speed capabilities, this machine can handle a large volume of doors in a short amount of time, increasing productivity and meeting tight deadlines.

The Orbital Stretch Wrapper also boasts an intelligent control system, equipped with user-friendly interfaces and customizable settings. This allows operators to easily adjust wrapping parameters such as wrap tension, speed, and film overlap to cater to specific packaging requirements. With its advanced technology, the machine can adapt to various door sizes and shapes, ensuring a secure and tight wrap every time.

Furthermore, the Automatic Orbital Stretch Wrapper features a cutting-edge film carriage system. This system optimizes film usage, reducing waste and saving costs. The machine utilizes a pre-stretch mechanism that elongates the film before it is applied to the cabinet door, maximizing its stretchability and minimizing film consumption. This not only reduces packaging material expenses but also contributes to a more sustainable and eco-friendly packaging process.

In addition to its impressive features, the Automatic Orbital Stretch Wrapper is built with durability and reliability in mind. Its robust construction and high-quality components guarantee long-term performance and minimal maintenance requirements. This ensures that your investment in the machine will yield significant returns and contribute to your overall operational efficiency.

Now that you have a comprehensive understanding of the Automatic Orbital Stretch Wrapper and its benefits, it's time to take your packaging process to the next level. With Plasticband's leading manufacturing expertise and commitment to customer satisfaction, you can trust that their packaging solutions will meet your specific needs.

So why wait? Upgrade your packaging process today with the Automatic Orbital Stretch Wrapper. Visit the leading manufacturer's website to explore their range of innovative packaging solutions and find the perfect fit for your business. Don't miss out on the opportunity to streamline your operations, improve efficiency, and protect your valuable cabinet doors during transit.

Check out the leading manufacturer for all your coil packing needs here: Orbital Stretch Wrapper

"Efficient and Reliable Orbital Cabinet Door Stretch Wrapping Machine for Streamlined Packaging"