Title: High-Speed Automatic Filling and Packing Machine - Revolutionizing Pot Filling and Sealing for Yoghurt Packaging

Description:

[Code Box]

Introduction:

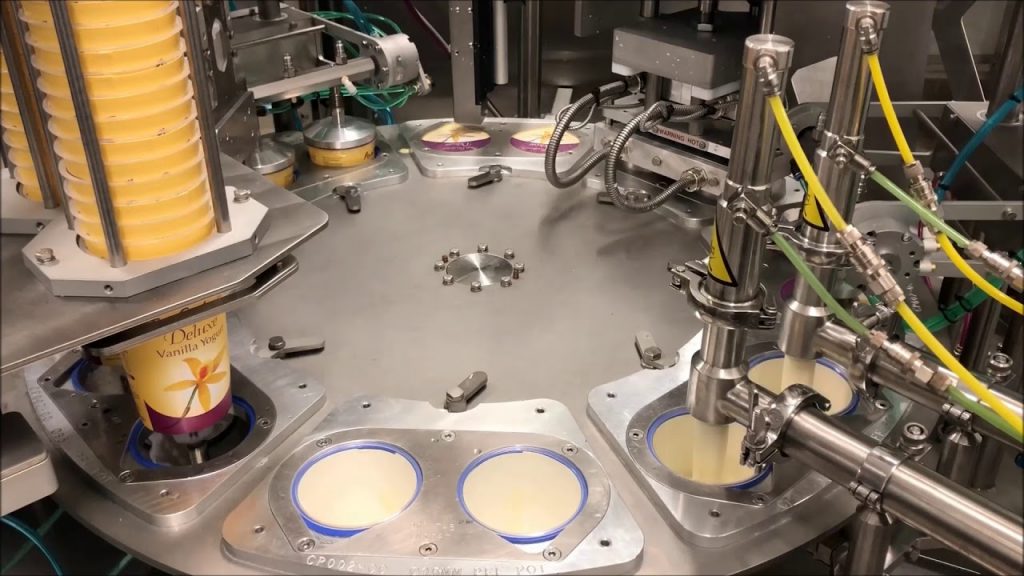

Welcome to our informative video showcasing the incredible capabilities of the Automatic Filling and Packing Machine, specifically the Rotofill Pot Filling and Sealing Machine designed for packing yoghurt. This versatile, high-speed rotary machine is a game-changer in the packaging industry, offering unlimited flexibility and exceptional performance to future-proof your production line.

Video Content:

In this video, we will provide a comprehensive overview of the Automatic Filling and Packing Machine, highlighting its key features, benefits, and operation steps. With a focus on the Rotofill Pot Filling and Sealing Machine, we will delve into the details and explain how it revolutionizes the packaging process for yoghurt products.

Key Features:

- Unlimited Flexibility: The Automatic Filling and Packing Machine is designed to adapt to various pot sizes and shapes, catering to different packaging needs. Its adjustable settings and customizable options ensure seamless integration into your production line.

- High-Speed Performance: With its advanced rotary technology, this machine enables rapid filling and sealing, significantly boosting productivity and efficiency.

- Precision and Accuracy: The machine ensures precise measurement and consistency in filling, guaranteeing the perfect portion of yoghurt in every pot.

- Future-Proof Solution: The Automatic Filling and Packing Machine is built to withstand evolving industry demands, offering scalability and adaptability for future growth.

Operation Steps:

1. Pot Loading: The machine's automated system efficiently loads empty pots onto the conveyor belt, ready for filling.

2. Filling Process: The Rotary Filling System accurately dispenses the desired quantity of yoghurt into each pot.

3. Sealing: Once filled, the pots move to the sealing station, where a reliable sealing mechanism securely seals the containers.

4. Labeling and Date Coding: The machine can be integrated with labeling and date coding systems to ensure product traceability and compliance.

5. Output and Packaging: Finally, the filled and sealed pots are discharged, ready for further packaging or distribution.

Call to Action:

If you found this video informative and valuable, please consider giving it a thumbs up, subscribing to our channel for more insightful content, and sharing it with others in the industry. Stay updated with the latest advancements in packaging technology by clicking the notification bell.

Additional Tags and Keywords:

Automatic Filling and Packing Machine, Rotofill Pot Filling and Sealing Machine, yoghurt packaging, high-speed rotary machine, packaging industry, flexibility, performance, future-proof, operation steps, precision, scalability, efficiency, labeling, date coding, productivity.

Hashtags:

#AutomaticFillingMachine #PackingMachine #PotFilling #SealingMachine #YoghurtPackaging #HighSpeedRotaryMachine #FutureProof #Productivity #Efficiency #Precision #Scalability #Labeling #DateCoding #PackagingTechnology

Here's a sample tilter for the Rotofill Pot Filling and Sealing Machine:

Title: Rotofill Pot Filling and Sealing Machine Tilter for Yoghurt Packaging

Introduction:

The purpose of this tilter is to provide a step-by-step guide on how to effectively use the Rotofill Pot Filling and Sealing Machine for packing yoghurt. This machine is designed to efficiently fill pots with yoghurt and seal them securely, ensuring product freshness and longevity. By following the instructions outlined below, operators can maximize the machine's potential and achieve optimal packaging results.

Materials Needed:

1. Rotofill Pot Filling and Sealing Machine

2. Yoghurt pots

3. Yoghurt supply

4. Sealing film

5. Cleaning supplies

Step 1: Machine Setup

1. Ensure that the Rotofill Pot Filling and Sealing Machine is clean and free from any residue.

2. Position the machine on a stable surface, allowing sufficient space for operation and easy access to the various components.

3. Connect the machine to a reliable power source, ensuring that all electrical connections are secure.

4. Ensure that the machine's settings are appropriate for the desired packaging requirements, such as pot size, filling amount, and sealing parameters.

Step 2: Preparation of Yoghurt Pots

1. Prepare clean yoghurt pots that are compatible with the machine's specifications, such as size and shape.

2. Ensure that the pots are free from any defects or damages that may compromise the sealing process.

3. Place the yoghurt pots in a convenient location near the machine, allowing easy access for filling.

Step 3: Filling the Yoghurt Pots

1. Open the machine's lid or access panel to reveal the filling station.

2. Pour the desired amount of yoghurt into the machine's designated reservoir or hopper.

3. Adjust the filling amount using the machine's controls to match the required quantity for each pot.

4. Position an empty yoghurt pot under the filling nozzle, ensuring proper alignment.

5. Activate the machine's filling mechanism, allowing the yoghurt to flow into the pot until the desired level is reached.

6. Repeat steps 4 and 5 for each pot, ensuring consistent filling.

Step 4: Sealing the Yoghurt Pots

1. Ensure that the sealing film is compatible with the machine and cut it into appropriate sizes.

2. Place a cut sealing film on top of a filled yoghurt pot, ensuring proper alignment and coverage.

3. Close the machine's lid or access panel to secure the pot and film in place.

4. Activate the sealing mechanism using the machine's controls, applying heat or pressure to seal the pot.

5. Wait for the sealing process to complete, ensuring a tight and secure seal.

6. Repeat steps 2 to 5 for each filled pot, maintaining a consistent sealing process.

Step 5: Machine Cleaning

1. After completing the filling and sealing process, power off the machine and unplug it from the electrical source.

2. Remove any remaining yoghurt from the machine's reservoir, hopper, and filling station.

3. Clean the machine thoroughly using appropriate cleaning supplies, ensuring all parts are free from residue or debris.

4. Allow the machine to dry completely before storing it in a clean and dry location.

Conclusion:

By following this tilter, operators can effectively utilize the Rotofill Pot Filling and Sealing Machine for packing yoghurt. It ensures that the machine is set up correctly, yoghurt pots are prepared properly, filling and sealing processes are performed accurately, and the machine is cleaned after use. Following these steps will lead to efficient yoghurt packaging, enhancing product quality and customer satisfaction. Automatic Packing Line

#Rotofill #Pot #Filling #Sealing #Machine #Packing #Yoghurt