Title: High-Speed Automated Tray Packer for Blister Packs of Batteries | Aagard's Innovation

Description:

Introduction:

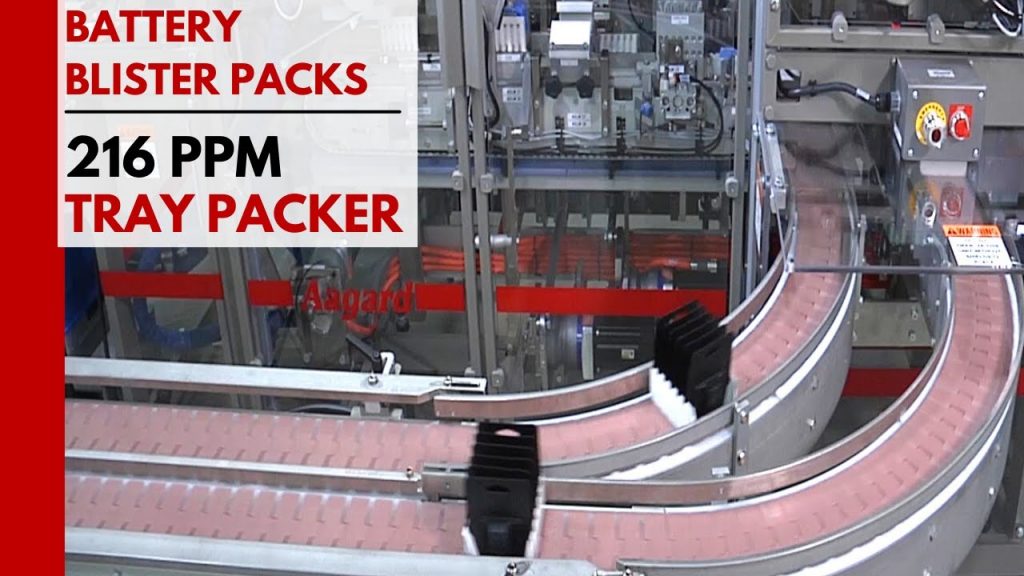

Welcome to our video showcasing the cutting-edge Automated Packing Systems, specifically the high-speed Automated Tray Packer designed for blister packs of batteries. In collaboration with Aagard, an industry leader in packaging solutions, this revolutionary system handles an impressive 216 products per minute. Get ready to explore the advanced features and seamless operation of this packaging system through our comprehensive video.

Video Content:

Our video dives deep into the functionalities and advantages of the Automated Tray Packer for Blister Packs of Batteries, developed by Aagard. This state-of-the-art packaging system utilizes gantry technology to ensure optimal efficiency and precision. With its remarkable speed and accuracy, it significantly enhances the productivity of battery packaging processes.

Key Highlights:

1. Lightning-fast Packing: Witness the astounding capability of the Automated Tray Packer as it swiftly handles 216 products per minute, streamlining your packaging operations like never before.

2. Custom Tray Packer: Discover how Aagard's tailored tray packer caters specifically to blister packs of batteries, ensuring a seamless fit and optimal protection during transportation.

3. Gantry Technology: Learn about the advanced gantry system employed in this packaging solution, which enables precise and consistent product placement with minimal errors.

4. Enhanced Efficiency: Experience the remarkable increase in productivity and reduced downtime achieved with the Automated Tray Packer, ultimately resulting in significant cost savings.

5. User-Friendly Interface: Explore the intuitive interface of the system, allowing operators to easily monitor and control various parameters for seamless operation.

Operation Steps:

Our video provides a step-by-step demonstration of the Automated Tray Packer for Blister Packs of Batteries, offering a comprehensive understanding of its operation. Witness how the system precisely loads blister packs onto trays, ensuring secure and efficient packaging. From the loading process to the final sealing stage, every step is executed flawlessly, ensuring the highest quality and consistency.

Call to Action:

If you found our video informative and captivating, we encourage you to like, subscribe, and share it with others who may benefit from this advanced packaging solution. Stay tuned for more exciting content on Automated Packing Systems and other innovative technologies in the industry.

Additional Tags and Keywords: Automated Packing Systems, Battery Packaging, Tray Packer, Blister Pack Automation, Packaging Technology, Gantry System, High-Speed Packaging, Aagard Innovation

Hashtags: #AutomatedPackingSystems #TrayPacker #BlisterPackAutomation #BatteryPackaging #GantryTechnology #PackagingSolutions #AagardInnovation

Title: Automated Tray Packer for Blister Packs of Batteries: Enhancing Efficiency and Productivity

Introduction:

In today's fast-paced manufacturing industry, efficiency and productivity are crucial for businesses to remain competitive. The introduction of automated tray packers for blister packs of batteries has revolutionized the packaging process, offering significant advantages over traditional manual methods. This article aims to present a tilter for an automated tray packer, highlighting its benefits, features, and how it enhances the overall efficiency and productivity of blister pack packaging.

1. Increased Efficiency:

The tilter is a fundamental component of an automated tray packer system for blister packs of batteries. It streamlines the packaging process by automatically tilting the trays, allowing for easy and precise placement of batteries. This eliminates the need for manual tilting, reducing the risk of errors and enhancing overall efficiency.

2. Precise Tray Positioning:

The tilter ensures accurate tray positioning, aligning the blister packs perfectly for further processing. It consistently maintains the correct orientation, preventing misaligned packs and reducing the chances of damage during packaging.

3. Versatile Tray Handling:

The tilter is designed to handle a wide range of blister pack tray sizes, accommodating various battery sizes and pack configurations. Its adaptability allows manufacturers to efficiently package batteries of different shapes and sizes, eliminating the need for multiple packaging machines.

4. Improved Safety:

Automated tray packers equipped with a tilter prioritize workplace safety. By eliminating manual tilting, the risk of ergonomic injuries such as strains and sprains is significantly reduced. This ensures a safer working environment for employees, minimizing downtime due to injuries.

5. Enhanced Productivity:

The tilter operates at high speeds, significantly increasing the packaging throughput. The automated process reduces the time required for tray handling, allowing for faster and more efficient production. This leads to higher productivity, meeting increased market demands and reducing overall production costs.

6. Integration with Existing Systems:

The tilter can seamlessly integrate with existing automated tray packer systems, maximizing the utilization of current equipment and minimizing additional investments. This makes it a cost-effective solution for manufacturers looking to enhance their packaging processes without significant disruptions or expenses.

Conclusion:

The tilter for an automated tray packer for blister packs of batteries offers substantial benefits in terms of efficiency, precision, versatility, safety, and productivity. Its ability to automate the tray tilting process ensures accurate positioning and reduces the risk of errors, leading to improved overall packaging quality. By integrating this technology into existing systems, manufacturers can enhance their production capabilities and stay ahead in a competitive market. Automatic Packing Line

#Automated #Tray #Packer #Blister #Packs #Batteries