Check out the cutting-edge automatic packing system offered by a leading manufacturer for professional packaging solutions. With the advancement in technology, companies are now embracing automated systems to streamline their packing processes and enhance efficiency. In this article, we will explore the benefits and features of an automatic packing system and how it can revolutionize your packaging operations.

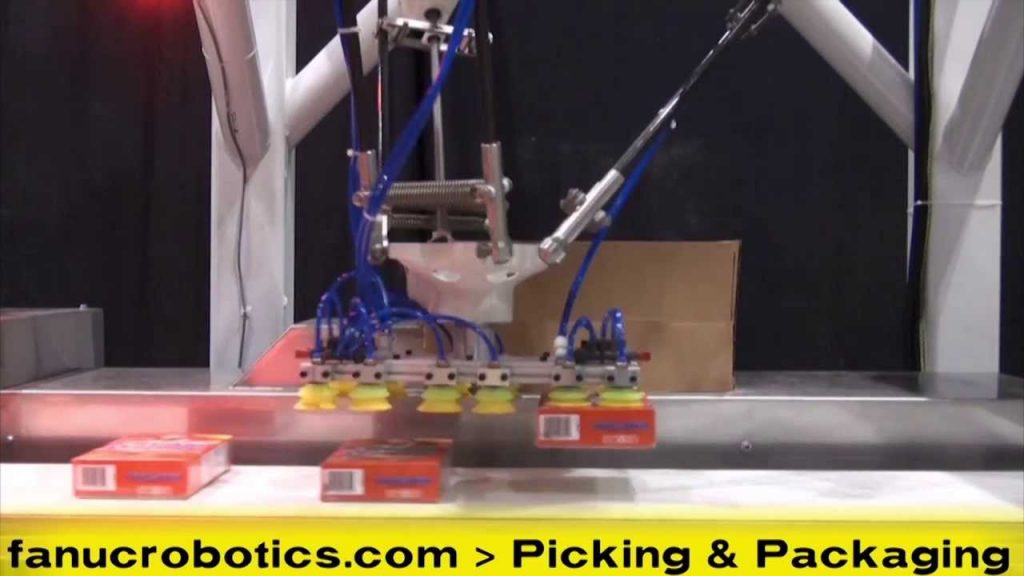

Automated packing systems have become an essential component for modern businesses. With the help of robotics and advanced technology, these systems can significantly improve packing speed, accuracy, and overall productivity. The FANUC M-3iA Four-Axis Delta Robot is a prime example of an automated packing system that offers exceptional performance and reliability.

One of the key advantages of an automatic packing system is its ability to handle a wide range of products and packaging materials. Whether you are dealing with boxes, bags, bottles, or other items, the system can be easily programmed to accommodate different shapes and sizes. This versatility eliminates the need for manual labor and ensures consistent packaging quality.

The FANUC M-3iA Four-Axis Delta Robot is equipped with advanced sensors and vision systems, allowing it to detect and handle products with precision. This ensures that each item is placed correctly and securely in the packaging, minimizing the risk of damage during transportation. Additionally, the system can efficiently handle fragile or delicate items, providing a gentle but efficient packing process.

Another significant advantage of an automatic packing system is its speed and efficiency. With the ability to pack products at high speeds, businesses can significantly increase their output and meet customer demands more effectively. This not only improves productivity but also reduces labor costs and optimizes overall operational efficiency.

Furthermore, automated packing systems offer enhanced safety features, reducing the risk of accidents and injuries in the workplace. The FANUC M-3iA Four-Axis Delta Robot is designed with built-in safety mechanisms, including collision detection sensors and emergency stop buttons. These features ensure a safe working environment for employees while maintaining high productivity levels.

Implementing an automatic packing system can also contribute to sustainability efforts. By optimizing packaging processes and reducing material waste, businesses can minimize their environmental impact. The system can be programmed to use the appropriate amount of packaging material, eliminating excess waste and promoting eco-friendly practices.

In conclusion, automated packing systems, such as the FANUC M-3iA Four-Axis Delta Robot, offer numerous benefits for businesses looking to enhance their packaging operations. From improved efficiency and productivity to enhanced safety and sustainability, these systems are revolutionizing the way companies pack their products. By embracing automation, businesses can stay ahead of the competition and deliver high-quality packaging solutions to their customers.

Check out the leading manufacturer's coil packing solutions for a professional and efficient packaging solution. With their expertise and cutting-edge technology, they can provide you with the perfect solution to meet your packaging needs. Don't miss out on the opportunity to revolutionize your packaging operations and take your business to new heights. Contact the leading manufacturer today for a customized and reliable automated packing system. Packing System

"Efficient Packaging with the Advanced M-3iA Four-Axis Delta Robot"