Title: Revolutionize Your Packaging Process with the FWC350 High-Speed Flow Wrapper | Automatic Packaging Line

Description:

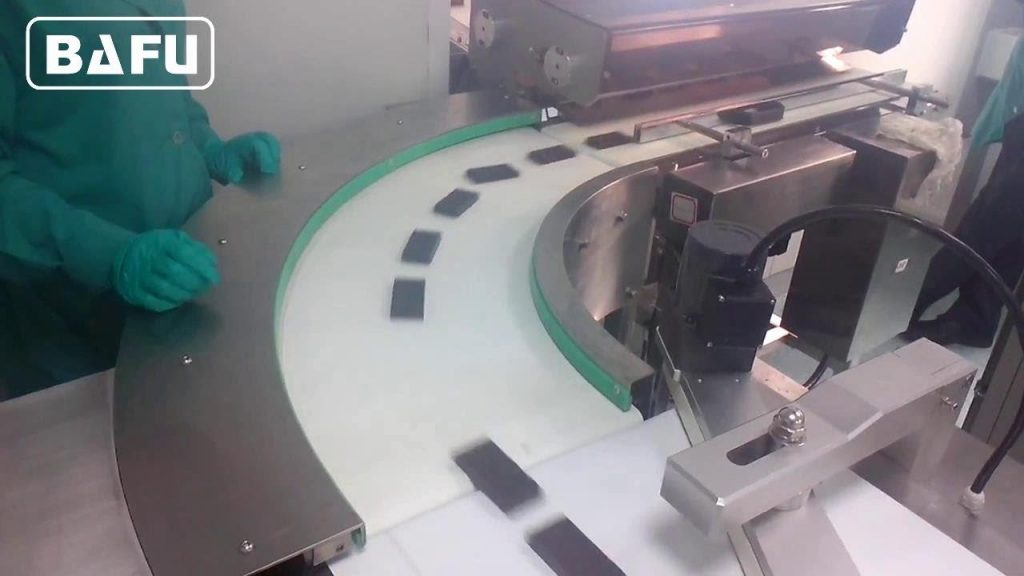

Welcome to our YouTube video showcasing the game-changing Automatic Packaging Line, specifically highlighting the cutting-edge FWC350 high-speed flow wrapper. If you're searching for an automated solution for bars packaging that guarantees efficiency and precision, you've come to the right place.

In this video, we delve deep into the world of automated packaging, presenting the FWC350 high-speed flow wrapper as the ultimate solution for small and medium-sized products. With its in-line feeder, this advanced machine seamlessly handles the automatic feeding and wrapping process, ensuring seamless operations and increased productivity.

[Heading 1: The Power of Automation]

Discover the immense power of automation as we explore the capabilities of the Automatic Packaging Line. Say goodbye to manual labor and tedious packaging processes, as this state-of-the-art system revolutionizes your production line. With its high-speed flow wrapper, you can achieve unrivaled efficiency and accuracy, allowing your business to thrive in today's competitive market.

[Heading 2: Unparalleled Speed and Precision]

Unleash the full potential of the FWC350 high-speed flow wrapper as we dive into its remarkable features. This advanced machinery boasts an impressive speed that enables it to handle a large volume of products in a short amount of time. Witness the precision and consistency it offers, ensuring that each item is perfectly wrapped and ready for distribution.

[Heading 3: Versatility for Various Products]

Whether you're packaging bars, snacks, or other small to medium-sized products, the Automatic Packaging Line has got you covered. The FWC350 high-speed flow wrapper is designed to accommodate a wide range of items, providing exceptional flexibility for your packaging needs. Its in-line feeder ensures a seamless feeding process, optimizing your production line's efficiency.

[Heading 4: Simplified Operation Steps]

We break down the operation steps of the Automatic Packaging Line, demonstrating how easy it is to integrate this innovative system into your production process. From initial setup to maintenance, you'll gain valuable insights into maximizing the potential of the FWC350 high-speed flow wrapper. Streamline your operations and reduce downtime with this user-friendly solution.

Don't forget to like, subscribe, and share this video to spread the word about the incredible capabilities of the Automatic Packaging Line and the FWC350 high-speed flow wrapper. Enhance your packaging process today and stay ahead of the competition.

Additional Tags and Keywords: automatic packaging, bars packaging, high-speed flow wrapper, automated packaging line, in-line feeder, packaging efficiency, productivity, packaging automation, advanced packaging solutions.

Hashtags: #AutomaticPackagingLine #FlowWrapper #PackagingAutomation #ProductivityBoost

Title: Automated Bars Packaging Tilter: Enhancing Efficiency in High-Speed Flow Wrapper and Automatic Packaging Line

Introduction:

In the fast-paced world of manufacturing, automated packaging solutions play a crucial role in optimizing productivity and ensuring consistent quality. With the rising demand for efficiently packaged bars, the need for a reliable and high-speed flow wrapper integrated with an automatic packaging line becomes increasingly important. This article introduces the concept of an Automated Bars Packaging Tilter, a solution designed to enhance efficiency and streamline the packaging process.

1. Streamlining the Packaging Process:

The Automated Bars Packaging Tilter is a cutting-edge technology that seamlessly integrates with high-speed flow wrappers and automatic packaging lines. Its primary objective is to optimize the packaging process by efficiently handling bars before and after the wrapping phase.

2. Efficient Bar Tilting Mechanism:

The tilter incorporates an advanced tilting mechanism that positions the bars in the optimal orientation for wrapping. By automatically aligning the bars in the correct position, the tilter eliminates the need for manual intervention, reducing human error and maximizing productivity.

3. Customizable Parameters:

The Automated Bars Packaging Tilter offers the flexibility to adjust various parameters according to specific bar dimensions, packaging requirements, and production line speeds. This customization ensures that the tilter can efficiently handle a wide range of bar sizes and shapes without compromising on speed or accuracy.

4. Seamless Integration with Flow Wrappers:

The tilter seamlessly integrates with high-speed flow wrappers, enabling a smooth transition from bar tilting to the actual wrapping process. The synchronized operation ensures a continuous and uninterrupted flow of bars, minimizing downtime and maximizing throughput.

5. Enhanced Packaging Line Efficiency:

By automating the tilting process, the tilter significantly reduces the time and effort required to position bars correctly for packaging. This enhanced efficiency translates into increased throughput, reduced labor costs, improved overall equipment effectiveness (OEE), and ultimately, higher profitability for manufacturers.

6. Quality Assurance:

The Automated Bars Packaging Tilter incorporates advanced sensors and control systems to ensure precise bar positioning, minimizing the risk of misalignment during the wrapping process. This feature guarantees consistent packaging quality, reducing the likelihood of product rejects and customer complaints.

7. User-Friendly Interface:

The tilter's user-friendly interface allows operators to easily control and monitor the tilter's performance. Detailed real-time data, including production rates, count, and error logs, facilitate effective decision-making and troubleshooting.

Conclusion:

The Automated Bars Packaging Tilter is an innovative solution that revolutionizes the packaging process for bars, offering increased efficiency, enhanced quality assurance, and seamless integration with high-speed flow wrappers and automatic packaging lines. By eliminating the need for manual bar positioning, this technology optimizes productivity, reduces labor costs, and ensures consistent packaging quality, ultimately benefiting manufacturers in the highly competitive market. Automatic Packing Line

#automated #bars #packaginghigh #speed #flow #wrapper #automatic #packaging #line