Are you in the market for a plastic injection machine? Look no further! In this article, we will explore the world of plastic injection machines and how they are revolutionizing the manufacturing industry. Whether you are a seasoned professional or just starting out, this article will provide you with valuable insights into the world of plastic injection machines.

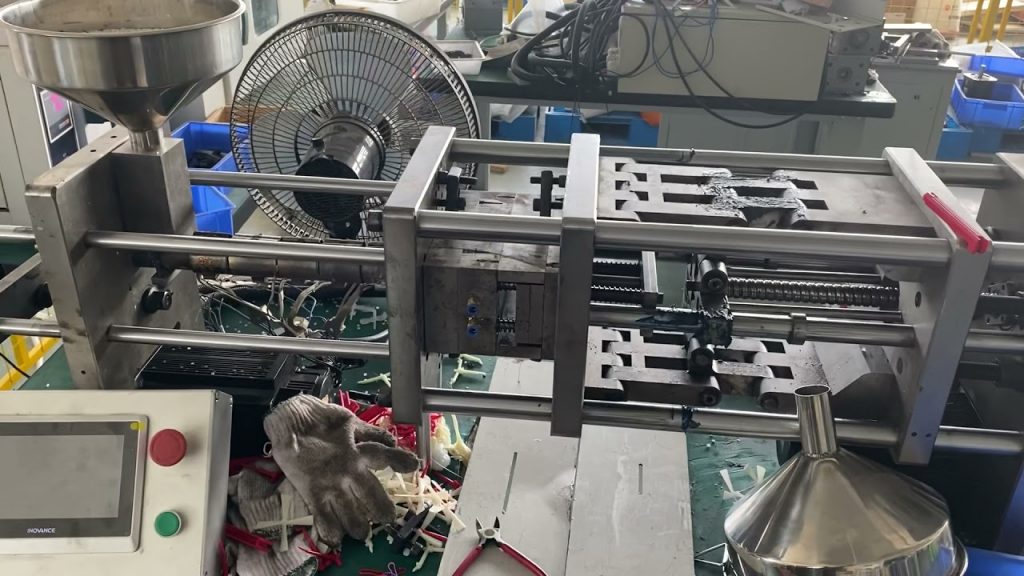

Plastic injection machines are a vital component in the manufacturing industry. They are used to create a wide range of products, from simple household items to complex automotive parts. These machines work by injecting molten plastic into a mold cavity, which then cools and solidifies to form the desired product. The process is fast, efficient, and highly accurate, making it a popular choice for manufacturers worldwide.

One of the key benefits of using a plastic injection machine is its versatility. These machines can produce a wide range of products, from small and intricate parts to large and complex components. This makes them an ideal choice for a variety of industries, including automotive, electronics, medical, and consumer goods.

Another advantage of plastic injection machines is their ability to produce high-quality products with minimal waste. The injection molding process allows for precise control over the shape, size, and texture of the product, resulting in consistent and uniform parts. Additionally, the ability to use recyclable plastics reduces the environmental impact of manufacturing.

Micro plastics injection molding machines are a specialized type of plastic injection machine that is designed for producing micro-sized parts. These machines are capable of producing extremely small, detailed, and intricate components with high precision. They are often used in industries such as electronics, medical devices, and telecommunications.

When choosing a plastic injection machine, there are several factors to consider. The size of the machine, the type of product you are manufacturing, and your production volume are all important considerations. It is also crucial to select a machine from a reputable manufacturer that offers reliable after-sales support and service.

To ensure the longevity and efficiency of your plastic injection machine, regular maintenance and inspection are essential. This includes cleaning and lubricating the machine, checking for any worn or damaged parts, and ensuring proper calibration. It is also important to follow the manufacturer's guidelines for operating the machine and to train your operators on proper usage and safety protocols.

In conclusion, plastic injection machines are a valuable tool in the manufacturing industry. Their versatility, precision, and efficiency make them an ideal choice for producing a wide range of products. Whether you are a small business owner or a large-scale manufacturer, investing in a plastic injection machine can greatly enhance your production capabilities.

Check out the leading manufacturers in the industry for professional coil packing solutions. They offer a wide range of options to meet your specific needs. Don't miss out on the opportunity to improve your packaging process and increase efficiency. Contact us today to learn more about our innovative solutions!

Remember, a plastic injection machine is not just a machine; it is an investment in the future of your business. Choose wisely and watch your production soar to new heights! Plastic Injection Machine

"Revolutionizing Plastic Manufacturing: Micro Plastics Injection Molding Machines and Plastic Injection Machines Unveiled!"