Check out the leading manufacturer for professional coil packing solutions here:

In today's ever-evolving manufacturing industry, the demand for high-quality plastic products is on the rise. One of the key processes involved in producing such products is plastic injection molding. This technique involves injecting molten plastic into a mold to create various shapes and sizes.

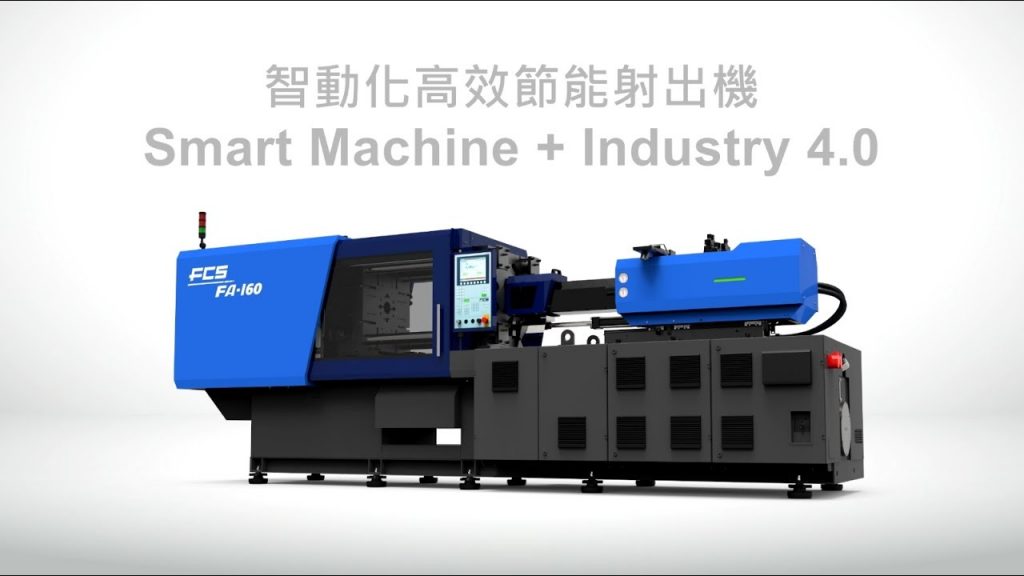

To ensure the success of plastic injection molding, it is crucial to have a reliable and efficient Plastic Injection Molding Machine. These machines play a significant role in achieving consistent and precise results. In this article, we will explore the features and benefits of a cutting-edge Plastic Injection Molding Machine, specifically the Smart Injection Molding Machine (FA Series) by FCS iMF 4.0.

Stabilization - The IMM has adaptive control to meet the slight fluctuations of molding condition.

One of the standout features of the Smart Injection Molding Machine is its adaptive control system, which allows it to handle even the slightest fluctuations in the molding conditions. This ensures that the machine can maintain stability throughout the entire molding process, resulting in consistent and high-quality plastic products.

Optimization - Applying process optimization for improved efficiency.

Efficiency is a top priority in any manufacturing process, and the Smart Injection Molding Machine excels in this aspect. By utilizing process optimization techniques, this machine maximizes productivity while minimizing waste. It streamlines the injection molding process, reducing cycle times and improving overall efficiency.

The FA Series of Smart Injection Molding Machines also incorporates advanced control algorithms that optimize the molding parameters. This optimization ensures that the machine operates at its peak performance, resulting in increased productivity and reduced energy consumption.

State-of-the-art technology - FCS iMF 4.0 revolutionizes the injection molding process.

FCS iMF 4.0 is a revolutionary technology developed by FCS, the leading manufacturer of plastic injection molding machines. It combines the power of Artificial Intelligence and Internet of Things (IoT) to create a smart and connected manufacturing environment.

With iMF 4.0, the Smart Injection Molding Machine becomes part of a larger network, allowing real-time monitoring and control of the entire production process. This connectivity enables predictive maintenance, remote troubleshooting, and data-driven decision-making, leading to enhanced productivity and reduced downtime.

The FA Series of Smart Injection Molding Machines also incorporates cutting-edge sensors and data analytics capabilities. These features enable the machine to collect and analyze data throughout the production process, providing valuable insights for process optimization and quality control.

In summary, the Smart Injection Molding Machine (FA Series) by FCS iMF 4.0 is a game-changer in the plastic injection molding industry. Its adaptive control system, process optimization capabilities, and integration with FCS iMF 4.0 technology make it a reliable and efficient choice for manufacturers.

Whether you are producing small plastic components or large-scale industrial products, investing in a high-quality Plastic Injection Molding Machine is essential. It ensures consistent and precise results, improves efficiency, and ultimately contributes to the success of your manufacturing operations.

So, if you are looking for a reliable and innovative solution for your plastic injection molding needs, be sure to check out the leading manufacturer of Plastic Injection Molding Machines. With their expertise and cutting-edge technology, they can provide you with the professional solution you need. Plastic Injection Machine

"Revolutionizing Injection Molding: Unveiling the Smart FA Series and FCS iMF 4.0 Innovations for Faster, Precise, and Efficient Plastic Molding"