If you are in the market for a small plastic injection machine, then you have come to the right place. In this article, we will explore the benefits of using a small plastic injection machine and how it can help you create high-quality plastic parts. Whether you are a hobbyist or a professional in the plastic molding industry, this article will provide you with all the information you need to know.

Introduction to Small Plastic Injection Machine

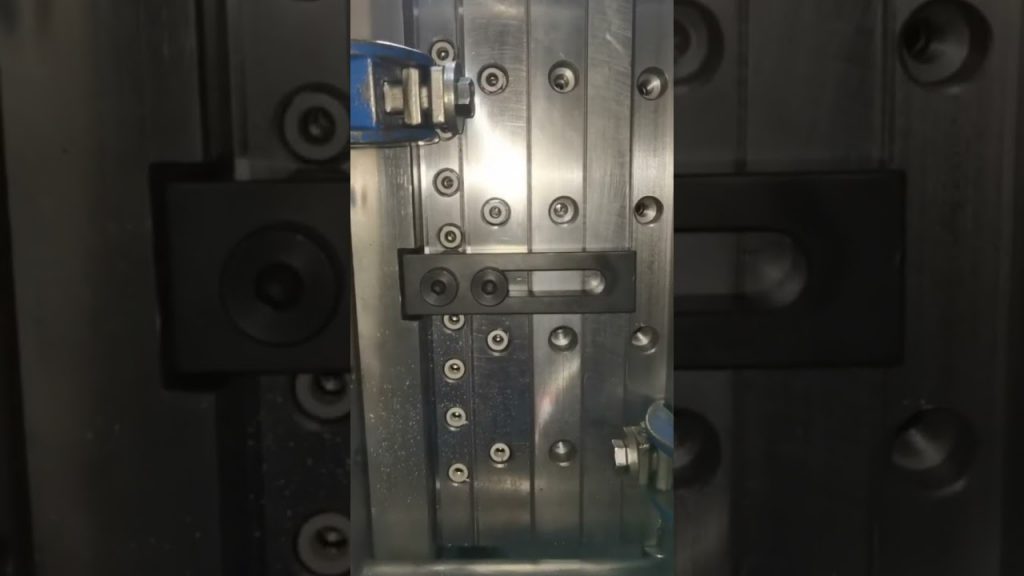

A small plastic injection machine is a compact and efficient tool used to create plastic parts through the process of injection molding. Injection molding is a manufacturing process in which molten plastic material is injected into a mold cavity, where it cools and solidifies to form the desired shape. Small plastic injection machines are specifically designed for molding small cavities plastic parts, making them ideal for industries that require precision and accuracy in their products.

Benefits of Small Plastic Injection Machine

There are several benefits to using a small plastic injection machine for your manufacturing needs. Firstly, the compact size of these machines makes them highly portable and easy to move around, allowing for greater flexibility in your production process. Additionally, small plastic injection machines are cost-effective, as they require less material and energy to operate compared to larger machines. This means that you can save on production costs without compromising the quality of your products.

Moreover, small plastic injection machines offer high precision and accuracy in the molding process. They are equipped with advanced control systems that allow for precise control of the injection speed, pressure, and temperature. This ensures consistent and uniform results, resulting in high-quality plastic parts. Whether you are creating intricate designs or simple shapes, a small plastic injection machine can meet your specific requirements.

Choosing the Right Small Plastic Injection Machine

When selecting a small plastic injection machine, there are several factors to consider. Firstly, you need to determine the size and complexity of the plastic parts you will be molding. This will help you determine the appropriate machine specifications, such as the clamping force, injection capacity, and mold size. Additionally, it is important to choose a machine that is user-friendly and easy to operate. Look for features such as a touch screen interface and intuitive controls to ensure a seamless production process.

Case Study: Injection Molding Machine for Small Cavities Plastic Part Mould Maker Factory

To illustrate the effectiveness of small plastic injection machines, let's take a look at a case study of a small cavities plastic part mould maker factory. This factory specializes in creating small plastic parts for various industries, including automotive, electronics, and packaging. By using a small plastic injection machine, they were able to achieve precise and consistent results, meeting the strict requirements of their clients.

The factory implemented a small plastic injection machine with advanced control systems, allowing them to adjust the injection speed, pressure, and temperature according to the specific requirements of each mold. This resulted in high-quality plastic parts with minimal defects and wasted materials. The small size of the machine also allowed for efficient use of space in the factory, optimizing their production process.

Conclusion

In conclusion, a small plastic injection machine is a valuable tool for anyone in the plastic molding industry. With its compact size, cost-effectiveness, and high precision, it offers numerous benefits for creating small cavities plastic parts. Whether you are a hobbyist or a professional, investing in a small plastic injection machine can greatly enhance your production process and help you achieve superior results.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Plastic Injection Machine

"Efficient Small Plastic Injection Machine for Precision Molding of Small Cavities in Plastic Parts - The Ultimate Guide"