Title: Industrial Packing Line | MAHARSHI IV Fluid Bottle Packing Line | Complete IV Fluid Bottle Packing Line

Description:

Introduction:

Welcome to our video showcasing the cutting-edge Industrial Packing Line, specifically the MAHARSHI IV Fluid Bottle Packing Line and the Complete IV Fluid Bottle Packing Line. In this video, we will explore the features, benefits, and operational steps of these advanced packaging solutions.

Video Content:

1. Overview of Industrial Packing Line:

- We begin by providing an in-depth overview of the Industrial Packing Line, which is revolutionizing the packaging industry with its high efficiency and precision.

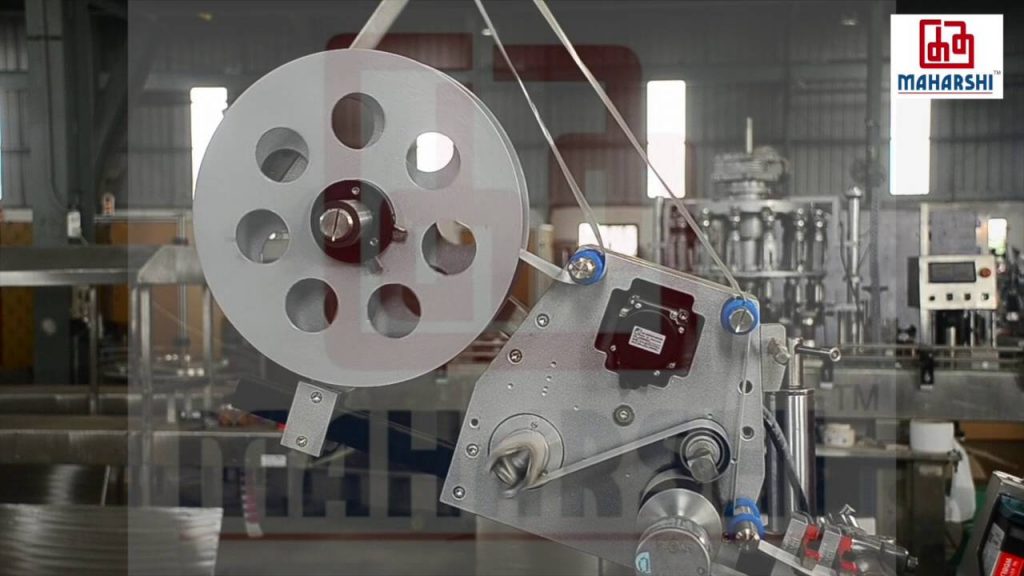

2. MAHARSHI IV Fluid Bottle Packing Line:

- Discover the innovative MAHARSHI IV Fluid Bottle Packing Line, designed to streamline the packaging process for IV fluid bottles. This state-of-the-art system ensures optimal accuracy and speed, reducing manual labor and increasing productivity.

3. Complete IV Fluid Bottle Packing Line:

- Dive into the details of the Complete IV Fluid Bottle Packing Line, a comprehensive solution that encompasses various stages of the packaging process. From bottle sorting and filling to capping and labeling, this system ensures seamless automation and maximum output.

4. Key Features and Highlights:

- Explore the key features of both the MAHARSHI IV Fluid Bottle Packing Line and the Complete IV Fluid Bottle Packing Line. Learn about their advanced technologies, customizable options, and how they meet the specific requirements of the pharmaceutical and healthcare industries.

5. Operational Steps:

- Gain a comprehensive understanding of the step-by-step operational process of these packing lines. We will guide you through each stage, highlighting the efficiency, accuracy, and reliability of the systems.

Call to Action:

If you found this video informative and valuable, we invite you to like, subscribe, and share it with others who may benefit from this technology. Stay updated with the latest advancements in the packaging industry by joining our community.

Additional Tags and Keywords:

Industrial packing line, MAHARSHI IV Fluid Bottle Packing Line, Complete IV Fluid Bottle Packing Line, packaging solutions, automation, pharmaceutical industry, healthcare industry, bottle sorting, filling, capping, labeling, advanced technologies, high efficiency.

Hashtags:

#IndustrialPackingLine #IVFluidPacking #AutomatedPackaging #PharmaceuticalPackaging #HighEfficiency

Here is a sample tilter for the Maharshi IV fluid bottle packing line:

Title: Maharshi IV Fluid Bottle Packing Line Tilter

Objective:

The objective of this tilter is to effectively and efficiently rotate fluid bottles to the desired position for packing on the Maharshi IV Fluid Bottle Packing Line.

Procedure:

1. Ensure that the tilter is properly installed and connected to the Maharshi IV Fluid Bottle Packing Line.

2. Perform a safety check to ensure all necessary safety precautions are in place before operating the tilter.

3. Place the fluid bottles on the conveyor belt leading to the tilter.

4. Activate the tilter by pressing the designated start button.

5. The tilter will receive the bottles from the conveyor and begin rotating them to the desired position.

6. Adjust the speed and angle of rotation as per the specifications of the fluid bottle packing line.

7. Monitor the tilter's performance to ensure bottles are properly rotated and aligned.

8. In case of any malfunction or deviation from the desired position, stop the tilter immediately and address the issue.

9. Once the bottles are correctly positioned, the tilter will transfer them to the next stage of the packaging line.

10. Regularly inspect and maintain the tilter to ensure its optimal performance.

Safety Precautions:

1. Ensure all operators are trained in the proper operation and safety guidelines of the tilter.

2. Always wear appropriate personal protective equipment (PPE) such as safety glasses and gloves.

3. Regularly inspect the tilter for any signs of wear and tear or malfunction.

4. Keep the working area clean and free from any obstructions.

5. Follow lockout/tagout procedures when performing maintenance or repairs on the tilter.

6. Do not overload the tilter beyond its specified capacity.

7. In case of emergency, have an emergency stop button easily accessible to immediately halt the tilter's operation.

Note: This tilter procedure is a general guideline and may need to be modified to fit the specific requirements and specifications of the Maharshi IV Fluid Bottle Packing Line. Always refer to the manufacturer's instructions and guidelines for accurate and safe operation. Automatic Packing Line

#MAHARSHI #FLUID #BOTTLE #PACKING #LINE