Check out our coil packing solution with a leading manufacturer for the professional solution right here:

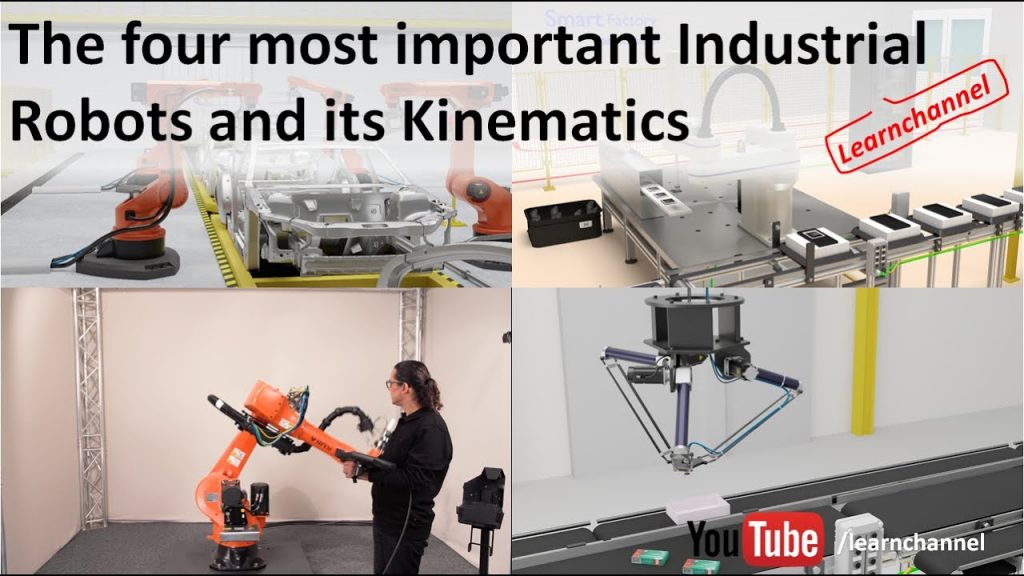

In this video, we will introduce you to the four most commonly used industrial robots, along with their kinematics and applications. Industrial robots have become an integral part of various industries, revolutionizing the way we manufacture and automate processes.

Types of Industrial Robots

Industrial robots come in different shapes and sizes, each designed for specific tasks and applications. Let's take a closer look at the most commonly used types:

1. Cartesian Robots:

Cartesian robots, also known as gantry robots, are characterized by their three linear axes of motion. These robots move in a rectangular Cartesian coordinate system, making them ideal for applications that require precise positioning and heavy payloads. They are commonly used in industries such as automotive, electronics, and packaging.

2. SCARA Robots:

SCARA robots, which stands for Selective Compliance Assembly Robot Arm, are widely used in assembly and pick-and-place applications. These robots have two parallel rotary joints and a prismatic joint, allowing them to move in a horizontal plane. SCARA robots offer high-speed and precise movement, making them suitable for applications in industries like electronics and pharmaceuticals.

3. Articulated Robots:

Articulated robots are known for their flexibility and versatility. These robots have multiple rotary joints, giving them a wide range of motion similar to a human arm. Articulated robots are commonly used in industries such as automotive, aerospace, and food processing. They can perform tasks like welding, material handling, and painting with great precision.

4. Delta Robots:

Delta robots, also known as parallel robots, are designed for high-speed and precise motion. These robots have a unique structure consisting of three or more arms connected to a common base. Delta robots are ideal for applications that require fast pick-and-place operations, such as packaging, sorting, and assembly in industries like food and pharmaceuticals.

Kinematics and Applications

Each type of industrial robot has its own kinematics, which refers to the study of motion without considering the forces that cause the motion. Understanding the kinematics of a robot is crucial for programming and optimizing its movements.

Cartesian robots utilize linear motion along three axes, making them suitable for tasks like palletizing, material handling, and assembly. SCARA robots excel in pick-and-place operations, assembly, and precision tasks requiring a high level of repeatability.

Articulated robots offer a wide range of motion and can perform complex tasks like welding, painting, and machine tending. Their versatility makes them valuable in various industries.

Delta robots are known for their speed and precision in pick-and-place operations. They are commonly used in industries that require high throughput and accuracy, such as packaging and sorting.

Conclusion

Industrial robots have revolutionized manufacturing processes across industries. Understanding the different types of industrial robots and their kinematics is essential for selecting the right robot for specific applications.

Whether it's Cartesian robots for precise positioning, SCARA robots for assembly, articulated robots for flexibility, or delta robots for high-speed operations, each type has its own unique capabilities and advantages.

By leveraging the power of industrial robots, businesses can increase productivity, improve efficiency, and enhance overall manufacturing processes.

Check out our coil packing solution with a leading manufacturer for the professional solution right here: [Insert URL]

*Note: This article is for informational purposes only and does not endorse any specific brand or company. Industrial Robot

"Revolutionizing Automation: Discovering the Kinematics and Types of Industrial Robots in Manufacturing Processes"