Title: Orbital Stretch Wrapper - Efficient Packaging Solution for Long Board, Steel Profile, Furniture, Door, Window, and More

Description:

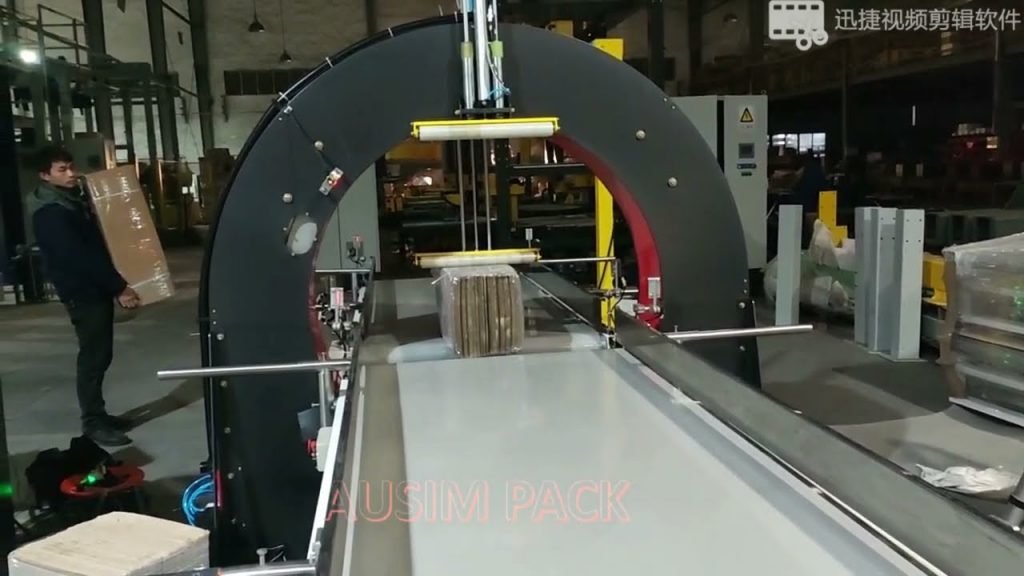

Welcome to our comprehensive video showcasing the incredible capabilities of the Orbital Stretch Wrapper, a cutting-edge orbital wrapping machine designed for efficiently packaging long board, long box, steel profile, furniture, door, window, steel, and wood box products. This horizontal stretch wrapping machine is widely recognized for its exceptional performance in securely winding and protecting various long items, including welded pipes and much more.

In this video, we will delve into the extensive features and benefits of the Orbital Stretch Wrapper, highlighting its versatility and suitability for different industries. Whether you are in the construction, manufacturing, logistics, or retail sector, this machine offers a reliable solution for your packaging needs.

[Heading 1: Key Features]

Discover the remarkable features that set the Orbital Stretch Wrapper apart from conventional packaging machines. With its advanced technology and innovative design, this machine offers:

1. Precise and Consistent Wrapping: Achieve consistent wrapping tension throughout the entire packaging process, ensuring product integrity and stability during transportation.

2. Adjustable Speed and Wrapping Patterns: Tailor the wrapping speed and patterns to match the unique requirements of your products, providing optimal protection and aesthetics.

3. User-Friendly Interface: Experience seamless operation with an intuitive interface that allows for easy adjustments and control.

4. Reliable Performance: Benefit from the robust construction and high-quality components, guaranteeing long-lasting performance and minimal maintenance requirements.

5. Versatile Compatibility: Accommodate a wide range of long products, including welded pipes, steel profiles, furniture, doors, windows, and wood boxes, enhancing the machine's flexibility in various industries.

[Heading 2: Video Content]

In this video, we will cover the following key points:

1. Introduction to the Orbital Stretch Wrapper: Get acquainted with the machine's purpose and its ability to streamline packaging processes.

2. Application in Different Industries: Explore the diverse applications of this machine across industries such as construction, manufacturing, and logistics.

3. Operation Steps: Understand the step-by-step process of operating the Orbital Stretch Wrapper, ensuring optimal results and efficiency.

4. Key Benefits and Advantages: Discover the advantages that this machine offers, including time and cost savings, enhanced product protection, and improved workflow.

5. Real-life Examples: Gain insights from real-life case studies and success stories, illustrating the machine's effectiveness in different scenarios.

[Heading 3: Call to Action]

If you found this video informative and helpful, we would greatly appreciate it if you could like, subscribe, and share it with your colleagues and industry peers. Stay up to date with our latest videos by subscribing to our channel.

[Heading 4: Additional Tags and Keywords]

Orbital Stretch Wrapper, Horizontal Stretch Wrapping Machine, Long Board Packaging, Steel Profile Wrapping, Furniture Packaging, Door and Window Wrapping, Steel Box Packaging, Wood Box Wrapping, Welded Pipes Packaging

[Heading 5: Hashtags]

#OrbitalStretchWrapper #StretchWrappingMachine #PackagingSolution #LongBoardPackaging #SteelProfileWrapping #FurniturePackaging #DoorWindowWrapping #SteelBoxPackaging #WoodBoxWrapping #WeldedPipesPackaging #EfficientPackaging

Here is a simple tilter program for an orbital wrapping machine that can handle long boards, long boxes, steel profiles, furniture, doors, windows, steel, and wooden boxes:

```

#include

void tiltLongBoard() {

// Code to tilt long board

std::cout << "Tilting long board..." << std::endl;

}

void tiltLongBox() {

// Code to tilt long box

std::cout << "Tilting long box..." << std::endl;

}

void tiltSteelProfile() {

// Code to tilt steel profile

std::cout << "Tilting steel profile..." << std::endl;

}

void tiltFurniture() {

// Code to tilt furniture

std::cout << "Tilting furniture..." << std::endl;

}

void tiltDoor() {

// Code to tilt door

std::cout << "Tilting door..." << std::endl;

}

void tiltWindow() {

// Code to tilt window

std::cout << "Tilting window..." << std::endl;

}

void tiltSteel() {

// Code to tilt steel

std::cout << "Tilting steel..." << std::endl;

}

void tiltWoodenBox() {

// Code to tilt wooden box

std::cout << "Tilting wooden box..." << std::endl;

}

int main() {

// Assuming you have a list of items to tilt

std::string items[] = {"long board", "long box", "steel profile", "furniture", "door", "window", "steel", "wooden box"};

int itemCount = sizeof(items) / sizeof(items[0]);

// Iterate through the items and call the respective tilter function

for (int i = 0; i < itemCount; i++) {

std::string currentItem = items[i];

if (currentItem == "long board") {

tiltLongBoard();

} else if (currentItem == "long box") {

tiltLongBox();

} else if (currentItem == "steel profile") {

tiltSteelProfile();

} else if (currentItem == "furniture") {

tiltFurniture();

} else if (currentItem == "door") {

tiltDoor();

} else if (currentItem == "window") {

tiltWindow();

} else if (currentItem == "steel") {

tiltSteel();

} else if (currentItem == "wooden box") {

tiltWoodenBox();

}

}

return 0;

}

```

This is a basic implementation that simulates the tilter program for different items. You can replace the placeholder code inside each tilter function with the actual code specific to your orbital wrapping machine.Orbital Stretch Wrapper

#orbital #wrapping #machine #long #board #long #boxsteel #profilefurnituredoorwindowsteelwoodbox