Title: Automatic Packaging Line - Car Air Filter Element Product Automatic Pillow Bag Packaging Machine

Description:

Introduction:

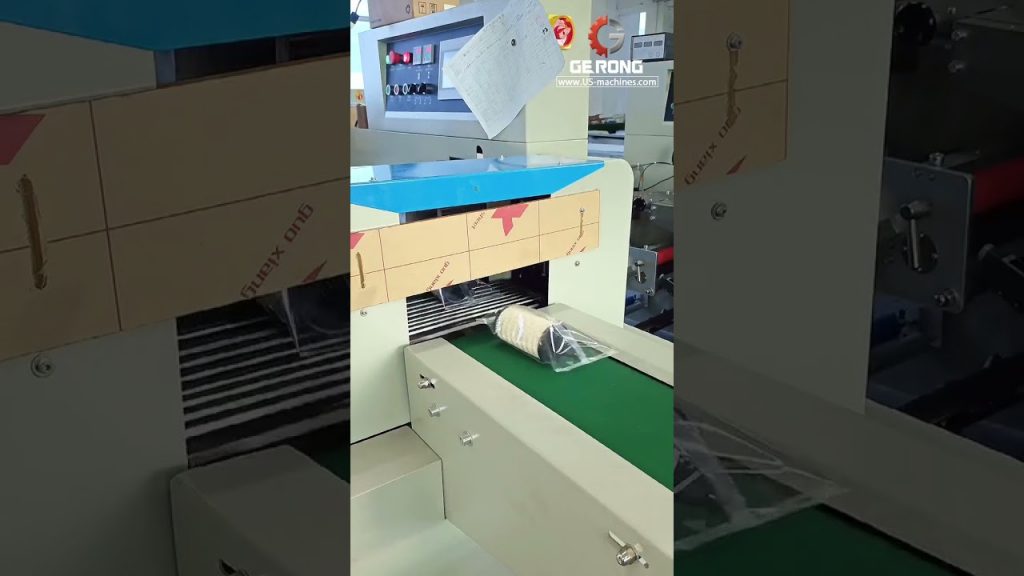

Welcome to our video showcasing the cutting-edge Automatic Packaging Line for Car Air Filter Element products. In this video, we present an innovative and efficient machine that automates the packaging process, ensuring quick and accurate pillow bag packaging.

Video Content:

Our Automatic Packaging Line is designed to streamline the packaging of Car Air Filter Element products. With its advanced technology, this machine guarantees high productivity and exceptional packaging quality.

Key Features:

1. Efficient Pillow Bag Packaging: The Automatic Packaging Line utilizes state-of-the-art technology to automatically package Car Air Filter Element products in pillow bags. This ensures consistent and visually appealing packaging every time.

2. Speed and Accuracy: With its automated operation, this machine can efficiently package a large volume of products, improving overall productivity. The precise packaging process guarantees accurate and reliable results.

3. Versatility: The Automatic Packaging Line is designed to accommodate various sizes and shapes of Car Air Filter Element products. This flexibility allows for easy adaptation to different packaging requirements.

4. Made in China & U.S. Standards Worldwide: Our machine adheres to both Chinese and U.S. quality standards, ensuring its reliability and durability. It combines the expertise of Chinese manufacturing with internationally recognized standards.

5. User-Friendly Interface: The machine features a user-friendly interface, making it easy to operate and adjust settings as needed. This simplifies the packaging process and minimizes the training required for operators.

Call to Action:

If you're looking for an efficient and reliable solution for packaging Car Air Filter Element products, our Automatic Packaging Line is the perfect choice. Don't forget to like, subscribe, and share this video to stay updated with the latest advancements in packaging technology.

Additional Tags and Keywords: Automatic packaging machine, pillow bag packaging, Car Air Filter Element packaging, packaging technology, efficient packaging, automated packaging line, packaging process, Chinese manufacturing, U.S. quality standards, productivity improvement.

Hashtags: #AutomaticPackagingLine #PillowBagPackaging #CarAirFilterElement #PackagingTechnology #Efficiency

Title: Automated Pillow Bag Packaging Machine for Car Air Filter Elements

Introduction:

In the automotive industry, the quality of air filters is critical to ensure optimal engine performance and longevity. To streamline the packaging process for car air filter elements, an automated pillow bag packaging machine offers efficiency, accuracy, and convenience. This article presents a comprehensive overview of a state-of-the-art pillow bag packaging machine designed specifically for car air filter elements.

1. High-Speed Packaging:

The automated pillow bag packaging machine is equipped with advanced technology that enables high-speed packaging. With a robust conveyor system and intelligent controls, it can efficiently handle a large volume of car air filter elements, minimizing production time and maximizing output.

2. Precise Placement:

Ensuring accurate placement of the air filter elements in the pillow bags is essential to maintain product integrity. The packaging machine incorporates cutting-edge sensors and precision-driven mechanisms to consistently position the filters within the bags, eliminating the risk of misalignment or damage during the packaging process.

3. Adjustable Bag Sizes:

Car air filter elements come in various sizes, which necessitates a flexible packaging system. The pillow bag packaging machine offers adjustable bag sizes, allowing manufacturers to accommodate different filter dimensions effortlessly. This adaptability enhances operational efficiency and reduces the need for manual adjustments, resulting in a more streamlined production process.

4. User-Friendly Interface:

To facilitate ease of use, the packaging machine features a user-friendly interface that enables operators to control and monitor the packaging process with simplicity. The intuitive touchscreen display provides real-time status updates, error alerts, and allows operators to access various settings, ensuring smooth operation and reducing downtime.

5. Automated Tilter Function:

An innovative feature of this packaging machine is its automatic tilter for air filter elements. This mechanism ensures that each filter is properly positioned within the pillow bag for optimal packaging. By eliminating the need for manual tilting, it enhances efficiency, reduces labor costs, and minimizes the risk of human error.

6. Quality Assurance:

The pillow bag packaging machine incorporates quality assurance mechanisms to guarantee the integrity of the packed car air filters. It includes sensors and detectors to identify any defects or inconsistencies in the filters, ensuring that only high-quality products are packaged and delivered to customers.

Conclusion:

The automated pillow bag packaging machine for car air filter elements revolutionizes the packaging process, offering speed, precision, and convenience. With its adjustable bag sizes, user-friendly interface, and automatic tilter function, it optimizes production efficiency while maintaining product quality. By investing in this advanced packaging machine, automotive manufacturers can elevate their operations and meet the growing demand for superior car air filter elements. Automatic Packing Line

#Car #air #filter #element #product #automatic #pillow #bag #packaging #machine