Title: Automatic Filling and Packing Machine: A Comprehensive Guide to DIY Automatic and Semi-Automatic Packaging

Description:

Introduction:

Welcome to our comprehensive guide on Automatic Filling and Packing Machines. In this video, we will provide you with an in-depth overview of DIY Automatic and Semi-Automatic Packaging Machines, their functionalities, and the benefits they offer to businesses in various industries.

Video Content:

In this video, we will delve into the world of Automatic Filling and Packing Machines, exploring their capabilities and applications. Our experts will guide you through the operation steps and highlight key points to help you understand the intricacies of these machines.

Key Highlights:

1. Advanced Packaging Technology: Discover the cutting-edge features and technologies incorporated in Automatic Filling and Packing Machines, ensuring accuracy, speed, and efficiency in the packaging process.

2. DIY Automatic Packaging: Learn about the advantages of DIY Automatic Packaging, empowering businesses to streamline their production lines and reduce dependence on manual labor.

3. Semi-Automatic Packaging: Explore the flexibility and cost-effectiveness of Semi-Automatic Packaging, enabling businesses to strike a balance between automation and manual intervention.

4. Operation Steps: Gain valuable insights into the step-by-step process of operating Automatic and Semi-Automatic Packing Machines, ensuring optimal performance and output.

5. Benefits and Applications: Understand the wide range of benefits these machines offer, including increased productivity, improved product quality, reduced wastage, and enhanced packaging precision. Explore the diverse industries that can benefit from Automatic Filling and Packing Machines, such as food and beverage, pharmaceuticals, cosmetics, and more.

Call to Action:

If you found this video informative and helpful, we encourage you to hit the like button and subscribe to our channel for more insightful content. Don't forget to share this video with others who might find it valuable.

Additional Tags and Keywords:

Automatic Filling and Packing Machine, DIY Automatic Packaging, Semi-Automatic Packing Machine, Packaging Technology, Operation Steps, Benefits of Automatic Packaging, Applications, Productivity Improvement, Packaging Precision, Cost-Effectiveness, Streamlined Production.

Hashtags:

#AutomaticFillingAndPackingMachine #DIYAutomaticPackaging #SemiAutomaticPacking #PackagingTechnology #ProductivityImprovement #PackagingPrecision #CostEffectiveness #StreamlinedProduction

Here's a sample tilter for a DIY Automatic & Semi-Automatic Packing Machine:

Title: DIY Automatic & Semi-Automatic Packing Machine Tilter: Streamline Your Packaging Process

Introduction:

- Save time and effort by building your own DIY Automatic & Semi-Automatic Packing Machine Tilter.

- This innovative tilter will revolutionize your packaging process, making it faster, more efficient, and hassle-free.

- In this guide, we will provide step-by-step instructions to help you construct your very own tilter at an affordable cost.

Section 1: Understanding the Benefits of a Packing Machine Tilter

- Define the purpose and advantages of using a packing machine tilter in your packaging operations.

- Highlight how it reduces manual effort, improves productivity, and enhances safety in the workplace.

- Discuss how the tilter ensures consistent and accurate packaging, reducing the risk of damage to products.

Section 2: Gathering the Required Materials and Tools

- Provide a comprehensive list of materials and tools needed to build the tilter.

- Include specific measurements and quantities required for each component.

- Suggest alternative options for certain materials to suit different budgets and availability.

Section 3: Step-by-Step Construction Guide

- Present detailed instructions on assembling the tilter, starting from the base structure.

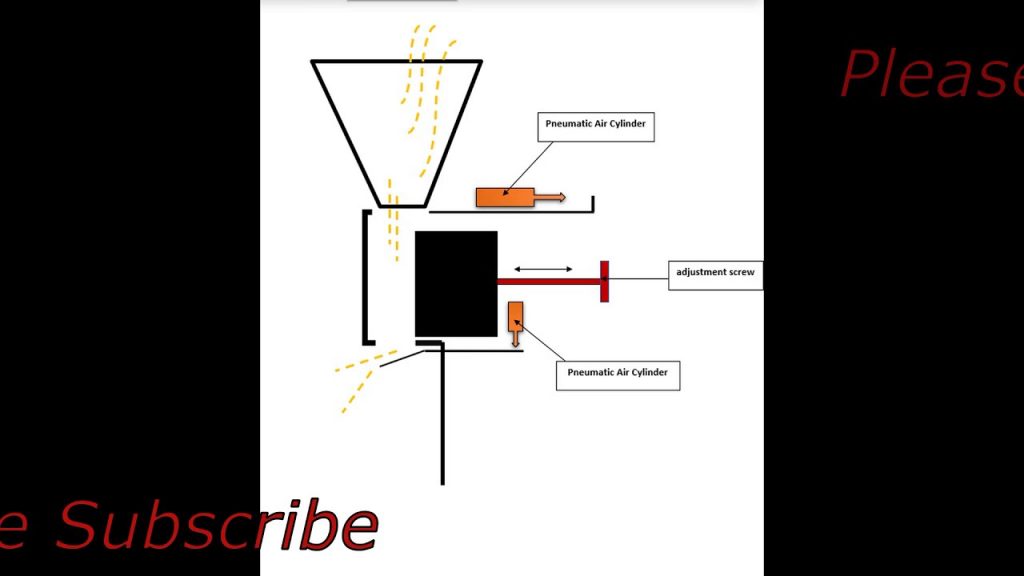

- Include diagrams, images, and measurements to ensure clarity and accuracy.

- Break down the process into manageable steps, allowing readers to easily follow along.

Section 4: Adding Automation and Semi-Automation Features

- Explain how to integrate automation and semi-automation capabilities into the tilter.

- Discuss the use of sensors, actuators, and control systems to automate the tilting process.

- Provide guidance on wiring and programming the tilter to achieve desired functionalities.

Section 5: Troubleshooting and Maintenance

- Offer troubleshooting tips and solutions for common issues that may arise during the tilter's operation.

- Provide recommendations for regular maintenance and upkeep to ensure optimal performance.

- Emphasize the importance of safety precautions and regular inspections.

Section 6: Final Thoughts and Future Enhancements

- Summarize the benefits and convenience of having a DIY Automatic & Semi-Automatic Packing Machine Tilter.

- Encourage readers to experiment and customize the tilter based on their unique packaging needs.

- Suggest potential upgrades or enhancements to further improve the tilter's capabilities.

Conclusion:

- Reiterate the advantages of using a DIY Automatic & Semi-Automatic Packing Machine Tilter in your packaging operations.

- Encourage readers to embark on their own tilter-building journey, highlighting the cost-effectiveness and flexibility of the DIY approach.

- Inspire readers to streamline their packaging processes and boost productivity with this innovative tilter. Automatic Packing Line

#DIY #Automatic #semiautomatic #Packing #Machine