Check out our video on Dyehome Intelligent's range of products, from semi-automatic wrapping machines to automatic packaging solutions. In this article, we will explore the benefits of using a Used Paper Packing Machine and how it is used in the packaging industry.

Introduction:

The packaging industry is constantly evolving, with new technologies and innovations being introduced to improve efficiency and productivity. One such innovation is the Used Paper Packing Machine, which offers a cost-effective and sustainable solution for packaging various products.

What is a Used Paper Packing Machine?

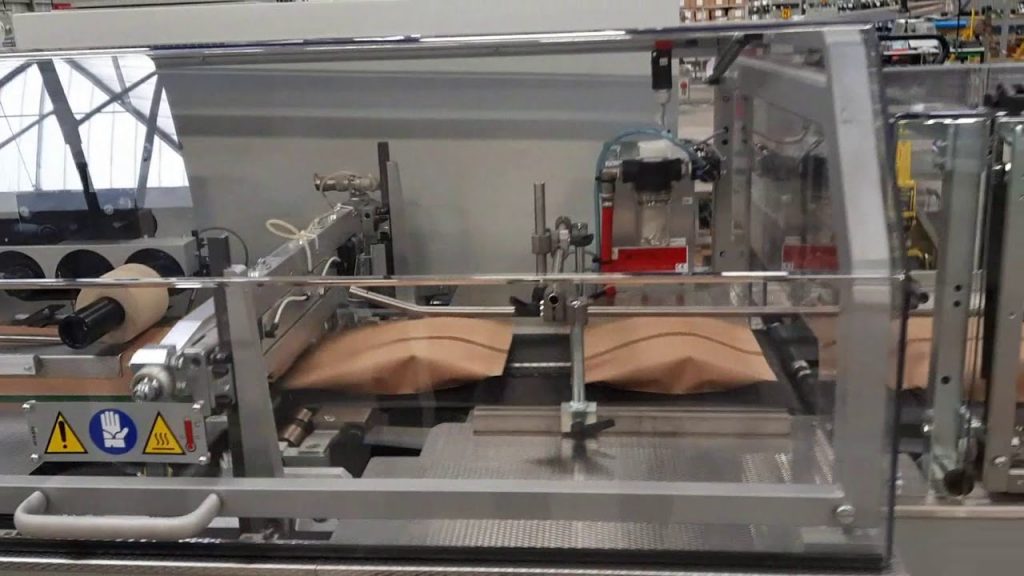

A Used Paper Packing Machine is a type of wrapping machine that is specifically designed to package products using paper as the primary material. It is an ideal solution for industries that require eco-friendly packaging options while also ensuring the protection of their products during transportation and storage.

Benefits of Using a Used Paper Packing Machine:

1. Sustainability: With increasing environmental concerns, businesses are looking for more sustainable packaging options. A Used Paper Packing Machine provides a solution by utilizing paper, a renewable and biodegradable material. By using paper instead of plastic, companies can significantly reduce their carbon footprint and contribute to a greener future.

2. Cost-effectiveness: Paper is generally more affordable than other packaging materials such as plastic or metal. By investing in a Used Paper Packing Machine, businesses can save on packaging costs in the long run. Additionally, the machine's efficiency ensures faster packaging processes, leading to increased productivity and reduced labor costs.

3. Versatility: Used Paper Packing Machines are highly versatile and can handle various products of different shapes and sizes. Whether it's packaging rolls of paper, textiles, or even food products, these machines can adapt to different packaging requirements, making them suitable for a wide range of industries.

How is the Paper Roll Wrapping Machine used?

The Paper Roll Wrapping Machine is a specific type of Used Paper Packing Machine designed to package paper rolls securely. Here are the steps involved in using a Paper Roll Wrapping Machine:

1. Preparation: Ensure that the machine is properly set up and all necessary materials, such as paper rolls and wrapping film, are ready.

2. Loading: Place the paper roll onto the machine's rotating platform, ensuring it is centered and balanced.

3. Wrapping: Activate the machine to start the wrapping process. The wrapping film will be automatically fed and tightly wrapped around the paper roll, ensuring its stability and protection.

4. Cutting and sealing: Once the wrapping is complete, the machine will cut and seal the film, securing it in place.

5. Unloading: Remove the wrapped paper roll from the machine's platform and proceed with further handling or storage.

Conclusion:

In conclusion, a Used Paper Packing Machine, particularly the Paper Roll Wrapping Machine, offers numerous benefits for businesses in need of sustainable and cost-effective packaging solutions. By investing in these machines, companies can reduce their environmental impact, save on packaging costs, and ensure the safe transportation of their products. If you're looking for a professional and reliable coil packing solution, we recommend checking out leading manufacturers in the industry.

Check out the coil packing solution with a leading manufacturer for the professional solution just here: [Insert relevant manufacturer link] Paper Packing Machine

"Efficient and Reliable Paper Roll Wrapping Machine: Unveiling Its Usage and Benefits"