Title: Complete Packaging Line for Pellet: Industrial Packing Line with VFFS MF 54, MF PCA SMART Cartesian Palletiser, and MF WRAP 35

Description:

Welcome to our comprehensive video showcasing the Industrial Packing Line, a complete packaging solution for pellets. This turn-key system is designed to optimize efficiency and productivity in the packaging process, ensuring seamless operations from start to finish.

Industrial Packing Line Components:

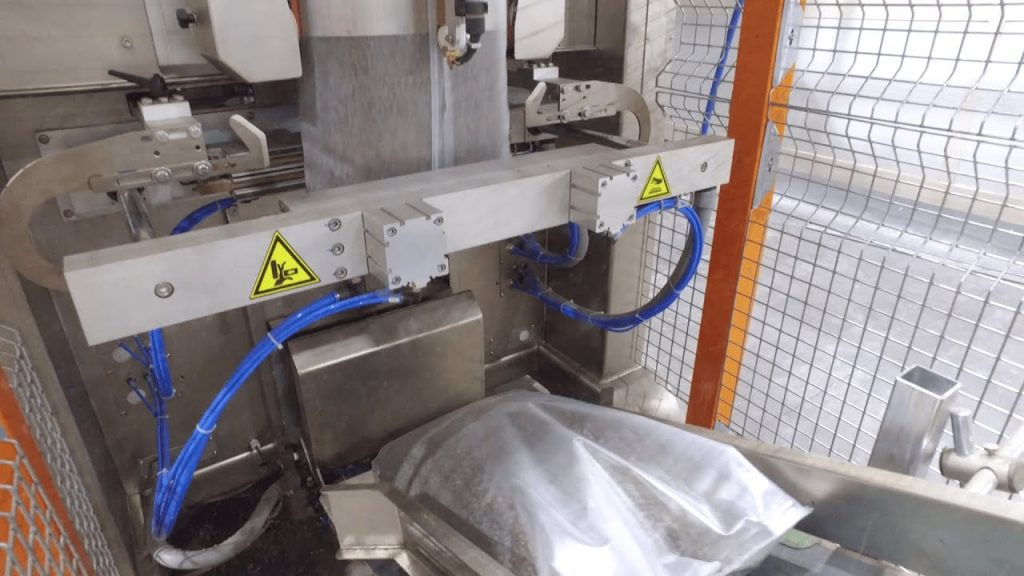

- VFFS MF 54: The VFFS MF 54 is a state-of-the-art vertical form-fill-seal machine that offers precise and efficient packaging for pellets. Its advanced technology enables high-speed filling and sealing, resulting in consistent and reliable packaging.

- MF PCA SMART Cartesian Palletiser: Our MF PCA SMART Cartesian Palletiser is an innovative solution for automated palletizing. This intelligent machine utilizes advanced robotics to stack and arrange packaged pellets onto pallets with utmost precision and accuracy, minimizing errors and maximizing efficiency.

- MF WRAP 35: The MF WRAP 35 is a cutting-edge wrapping machine that ensures secure and stable packaging of palletized pellets. With its adjustable settings and advanced features, it provides optimal protection for your products while maintaining excellent load stability.

Key Highlights and Operation Steps:

In this video, we will guide you through the entire packaging process using the Industrial Packing Line. We'll demonstrate the key highlights and operation steps, allowing you to gain a comprehensive understanding of the system's capabilities and benefits.

From the initial filling and sealing of the pellets with the VFFS MF 54 to the precise palletizing process with the MF PCA SMART Cartesian Palletiser, and finally, the secure wrapping with the MF WRAP 35 – each step will be explained in detail, highlighting the efficiency, accuracy, and reliability of this complete packaging line.

Call to Action:

If you found this video informative and helpful, please consider liking, subscribing, and sharing it with others in the industry. Don't forget to hit the notification bell to stay updated with our latest content.

Additional Tags and Keywords:

Industrial packing line, complete packaging line, pellet packaging, VFFS MF 54, MF PCA SMART Cartesian Palletiser, MF WRAP 35, pellet packaging system, turn-key packaging solution, automated palletizing, wrapping machine, efficient packaging, reliable packaging, high-speed filling, precise sealing, optimized efficiency, seamless operations.

Hashtags:

#IndustrialPackingLine #PelletPackaging #CompletePackagingSolution #VFFSMF54 #MFPcaSmartCartesianPalletiser #MFWrap35 #AutomatedPalletizing #EfficientPackaging #ReliablePackaging #TurnkeyPackaging

Title: Streamlining Your Pellet Packaging Process: A Complete Packaging Line Solution

Introduction:

In the fast-paced world of manufacturing, optimizing efficiency and productivity is crucial for businesses to stay competitive. When it comes to packaging pellets, having a complete packaging line can greatly enhance your operations. This article presents a comprehensive guide to setting up a packaging line specifically designed for pellet packaging, offering a streamlined solution to meet your packaging needs.

1. Automated Bagging Machine:

The first component of a pellet packaging line is an automated bagging machine. This machine is designed to accurately and efficiently fill bags with pellets. It can handle various bag sizes and weights, allowing for flexibility in your packaging options. The automated bagging machine eliminates the need for manual labor, reducing the risk of errors and increasing the overall speed of the process.

2. Conveyor System:

A conveyor system is an essential part of any packaging line. It transports the filled bags from the bagging machine to the next stage of the packaging process. The conveyor system can be customized to fit the layout of your facility, ensuring a smooth and seamless transition between different packaging stages. It also helps to maintain a continuous flow of bags, minimizing downtime and maximizing productivity.

3. Checkweigher:

To ensure accurate weight measurements of the filled bags, a checkweigher is an indispensable tool in the packaging line. This equipment automatically weighs each bag and compares it to a pre-set target weight. If any bags are outside the acceptable weight range, they are flagged for inspection or removal. This quality control measure guarantees consistency and prevents under or overfilled bags from reaching customers.

4. Metal Detector:

Another important component of the pellet packaging line is a metal detector. Metal contaminants can be present in the pellets, which can be hazardous to end-users. A metal detector scans each bag for any metal particles, ensuring that only safe and contaminant-free pellets are packaged. If any metal is detected, an alarm is triggered, and the bag is diverted for further inspection or removal.

5. Palletizing System:

The final stage of the packaging line is the palletizing system. This system automatically stacks filled bags onto pallets, ready for shipping or storage. It can be configured to arrange the bags in various patterns, maximizing space utilization and stability. The palletizing system eliminates the need for manual labor, reducing the risk of injuries and increasing efficiency.

Conclusion:

Investing in a complete packaging line specifically designed for pellet packaging can significantly improve your operational efficiency, product quality, and customer satisfaction. With automated bagging machines, conveyor systems, checkweighers, metal detectors, and palletizing systems, you can streamline your packaging process, reduce labor costs, and minimize errors. Embracing this comprehensive solution will help you stay ahead in the competitive market while meeting the growing demand for pellet packaging. Automatic Packing Line

#Complete #packaging #line #Pellet