Filling and Sealing Machine - A Revolutionary Solution for Packaging Needs

Introduction:

In today's fast-paced world, efficient packaging solutions are vital for businesses to meet the demands of their customers. One such solution that has gained immense popularity is the Filling and Sealing Machine. This innovative technology has revolutionized the packaging industry by providing a seamless and efficient way to fill and seal various products. In this article, we will explore the benefits and features of the Filling and Sealing Machine, with a specific focus on the Aseptic Blow-Fill-Seal System for Plastic Container Parenterals (BFS MACHINE).

The Importance of Packaging:

Packaging plays a crucial role in product preservation, transportation, and consumer satisfaction. It not only protects the product from external factors but also enhances its shelf appeal. With the increasing demand for packaged products, businesses are constantly seeking efficient and reliable packaging solutions.

Introducing the Filling and Sealing Machine:

The Filling and Sealing Machine is a versatile and advanced technology designed to streamline the packaging process. It provides a comprehensive solution for filling and sealing various types of products, including liquid, semi-liquid, and powder-based substances. This machine offers exceptional accuracy, speed, and efficiency, making it an ideal choice for industries such as pharmaceuticals, food and beverages, cosmetics, and more.

Features of the Filling and Sealing Machine:

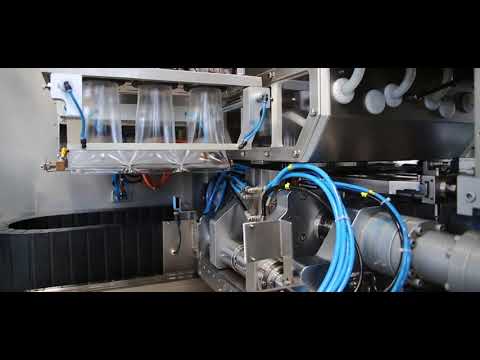

1. Aseptic Blow-Fill-Seal System for Plastic Container Parenterals (BFS MACHINE):

The Aseptic Blow-Fill-Seal System for Plastic Container Parenterals, commonly known as the BFS MACHINE, is a state-of-the-art technology that ensures aseptic packaging of pharmaceutical products. This system eliminates the need for traditional filling and sealing methods, reducing the risk of contamination and increasing product safety.

2. Precision and Accuracy:

The Filling and Sealing Machine guarantees precise and accurate filling and sealing of products, minimizing wastage and ensuring consistent quality. Its advanced technology and automated processes enable precise control over product quantity, ensuring that each package is filled to the desired level.

3. Speed and Efficiency:

With its high-speed capabilities, the Filling and Sealing Machine significantly increases production efficiency. It can handle a large volume of packaging in a short period, reducing production time and costs. This allows businesses to meet tight deadlines and cater to the ever-increasing market demands.

4. Versatility:

The Filling and Sealing Machine is designed to accommodate various packaging requirements. It can handle different container sizes, shapes, and materials, providing flexibility for businesses to package their products according to their specific needs.

Conclusion:

The Filling and Sealing Machine has revolutionized the packaging industry with its exceptional features and benefits. From ensuring aseptic packaging to enhancing production efficiency, this technology has become an integral part of various industries. By investing in a Filling and Sealing Machine, businesses can streamline their packaging process, improve product quality, and meet the demands of their customers effectively.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Filling Packing Machine

"Efficient Blow-Fill-Seal System: Streamlining Plastic Container Filling and Sealing Process"