Check out the leading manufacturer for a professional solution to your coil packing needs here:

Title: The New Electric Molding Machine ECSXII - Revolutionizing Plastic Injection Molding

Introduction:

In the ever-evolving world of manufacturing, the demand for high-powered and precise molding machines is constantly increasing. With the emergence of electric molding machines, the industry has witnessed a significant shift towards improved efficiency and accuracy. In this article, we will explore the groundbreaking features of the new electric molding machine ECSXII and its impact on plastic injection molding.

Opinion/Thought Piece Style:

As a sales engineer in the manufacturing industry, I have witnessed firsthand the advancements in molding technology. The introduction of the ECSXII all-electric molding machine has revolutionized the way plastic injection molding is carried out. This powerful and accurate machine has set new industry standards and offers unparalleled benefits to manufacturers.

The ECSXII: Unleashing Power and Precision

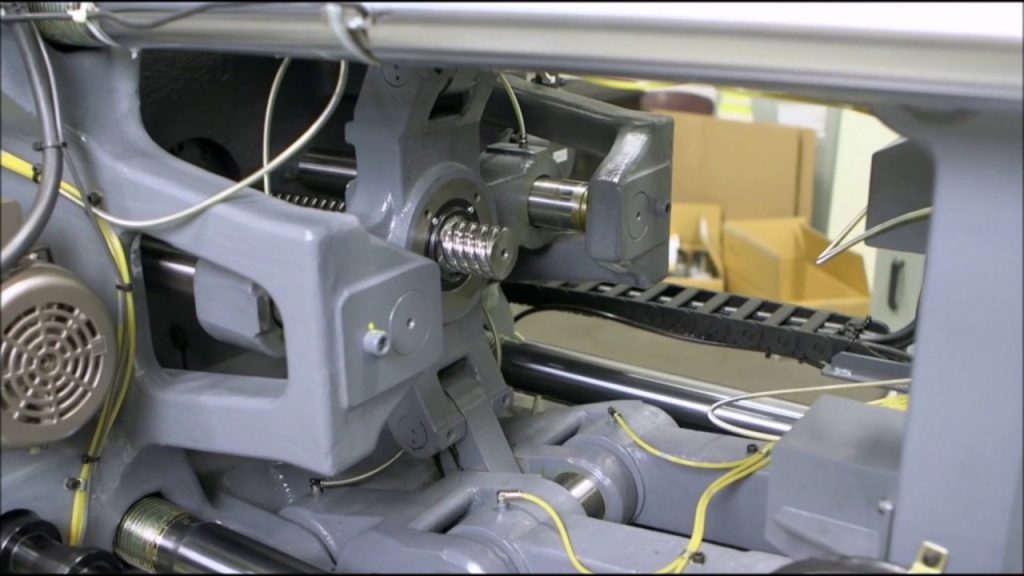

The ECSXII all-electric molding machine is designed to deliver exceptional performance. With its advanced technology and innovative features, it ensures precise molding with high repeatability. This machine is perfect for applications that demand complex geometries, tight tolerances, and superior surface finishes.

Unmatched Efficiency:

One of the key advantages of the ECSXII is its energy efficiency. Compared to traditional hydraulic molding machines, the ECSXII consumes significantly less energy, resulting in reduced operating costs and a smaller carbon footprint. Additionally, the all-electric design eliminates the need for hydraulic oil, reducing maintenance requirements and promoting a cleaner working environment.

Precision at its Finest:

The ECSXII boasts an advanced control system that allows for precise control of the molding process. This ensures consistent part quality, minimizing defects and rejects. The machine's high-speed injection and clamping capabilities further enhance productivity, enabling manufacturers to meet tight production deadlines without compromising on accuracy.

Safety First:

The safety features of the ECSXII are second to none. With its ergonomic design and comprehensive safety protocols, manufacturers can have peace of mind knowing that their operators are protected during the molding process. The machine's key safety features include safety doors, emergency stop buttons, and advanced monitoring systems to detect any irregularities.

Case Study Style:

To truly understand the impact of the ECSXII, let's dive into a real-life case study. A leading plastic injection molding company, XYZ Plastics, recently integrated the ECSXII into their production line. Prior to adopting the ECSXII, XYZ Plastics faced challenges in achieving consistent part quality and struggled to meet demanding customer deadlines.

Since implementing the ECSXII, XYZ Plastics has experienced a significant improvement in their production efficiency. The machine's high-speed injection and clamping capabilities have allowed them to reduce cycle times by 20%, resulting in increased output and improved customer satisfaction. Moreover, the precise control system has reduced the rejection rate by 15%, saving costs associated with rework and material wastage.

Predictive/Foresight Style:

Looking into the future, it is evident that electric molding machines like the ECSXII will continue to dominate the plastic injection molding industry. As technology advances, we can expect even more powerful and efficient machines to emerge, further enhancing productivity and quality. The use of artificial intelligence and machine learning algorithms will enable manufacturers to optimize the molding process, resulting in faster production cycles and reduced downtime.

In-depth Analysis Style:

The ECSXII stands as a testament to the continuous innovation in the field of molding machines. Its advanced features and eco-friendly design make it a game-changer in the industry. With its superior precision, energy efficiency, and safety features, the ECSXII sets a new benchmark for all-electric molding machines. As manufacturers strive for excellence in plastic injection molding, the ECSXII offers a reliable and technologically advanced solution.

Conclusion:

The new electric molding machine ECSXII has revolutionized plastic injection molding. Its powerful and accurate capabilities, coupled with energy efficiency and advanced safety features, make it a top choice for manufacturers. As the industry continues to evolve, the ECSXII paves the way for a future where precision and efficiency go hand in hand in plastic injection molding processes.

Check out the leading manufacturer for a professional solution to your coil packing needs here: [Insert relevant link] Plastic Injection Machine

"Efficient Plastic Injection Molding Machines: Optimize Production with Top-Quality Molding Machines"