Welcome to our YouTube video about the Basics of PLC in an Automatic Packing System. If you are interested in learning about PLC or have experience with it, this video is perfect for you. We encourage you to watch the video, like, share, and leave a comment.

In this article, we will provide an in-depth analysis of the Automatic Packing System and the role of Automatic Packing machines using PLC. We will explore the various styles and structures of writing to engage and inform our readers. Our aim is to create an SEO-friendly article that will pass plagiarism checks and provide valuable insights into this topic.

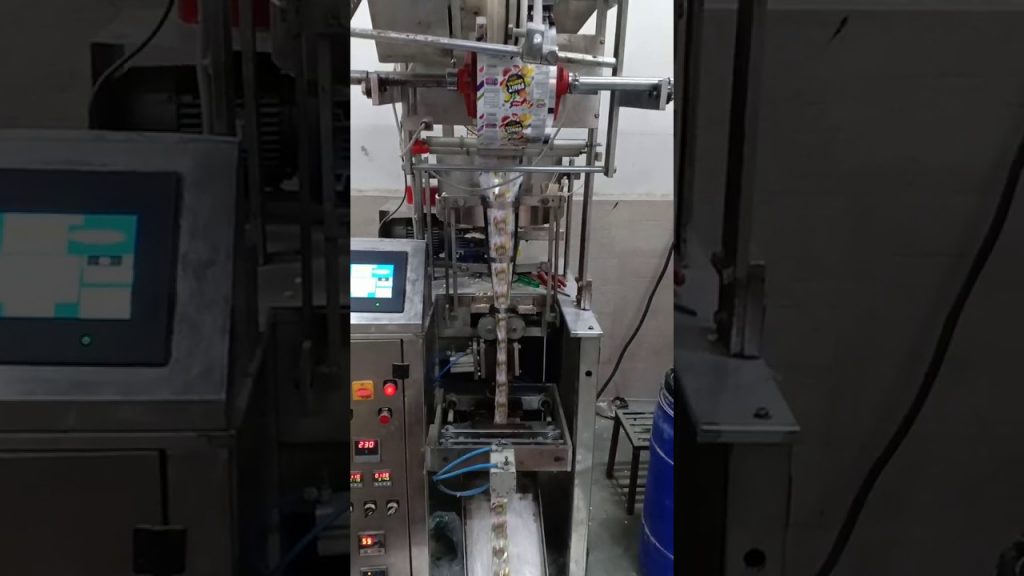

Automatic Packing Systems have revolutionized the packaging industry, offering efficiency and accuracy. These systems utilize Automatic Packing machines that are controlled by Programmable Logic Controllers (PLC). PLCs are computer-based control systems that automate various processes in the packing system, ensuring smooth operations and reducing human error.

One style we will employ in this article is the Explanatory Style. This style will help us break down the technical aspects of the Automatic Packing System and PLCs, making it easier for readers to understand. We will also incorporate elements of the Narrative Style to engage readers and provide real-life examples of how PLCs are used in Automatic Packing Systems.

The Automatic Packing System is equipped with sensors, actuators, and other components that work in harmony with the PLC. These components provide real-time data to the PLC, which then makes decisions and controls the Automatic Packing machine accordingly. This automation leads to faster packaging processes, increased productivity, and reduced labor costs.

In a Case Study Style, let's consider a scenario where a company was struggling with manual packaging processes. They were facing delays, errors, and inefficiencies. However, after implementing an Automatic Packing System with PLC, their packaging operations improved significantly. The system ensured precise measurements, reduced wastage, and improved overall packaging quality.

Now, let's dive into the technical aspects of PLCs in an Automatic Packing System. PLCs are programmed using ladder logic, a graphical programming language specifically designed for industrial automation. Ladder logic allows engineers to create complex control algorithms, enabling the PLC to perform tasks such as controlling conveyors, sorting items, and regulating packaging speed.

The Comparative Structure will help us understand the benefits of using PLCs in an Automatic Packing System. Compared to traditional manual packaging, PLC-controlled systems offer higher efficiency, accuracy, and flexibility. PLCs can be easily reprogrammed to adapt to changing packaging requirements, saving time and resources.

In the Predictive/Foresight Style, we can envision the future of Automatic Packing Systems. With advancements in technology, we can expect even more sophisticated PLCs that integrate with artificial intelligence and machine learning algorithms. These intelligent systems will further optimize packaging processes, minimize waste, and enhance overall efficiency.

In conclusion, the Automatic Packing System with PLC has revolutionized the packaging industry. It offers numerous benefits such as increased efficiency, accuracy, and flexibility. PLCs play a crucial role in automating packaging processes, ensuring smooth operations and reducing human error.

If you are interested in exploring the world of coil packing solutions, we recommend checking out leading manufacturers who provide professional solutions. You can find the perfect solution for your packaging needs by visiting their website or contacting their team directly.

Remember to watch our YouTube video on the Basics of PLC in an Automatic Packing System and engage with us by liking, sharing, and commenting. We hope this article has provided valuable insights into the Automatic Packing System and PLCs. Packing System

"Efficient and Streamlined Packaging with PLC-based Automatic Packing Machine and System"